Image Credit: MIT/Self-Assembly Lab

As a society we are constantly revolutionizing the materials we use. We have created 3D printers that print out digital shapes for us and now we have created printers that produce materials capable of assembling themselves. These self assembling 4D printed objects of the future are quickly becoming a reality in the present.

What is 4D Printing?

The term '4D printing' essentially refers to 3D printed objects that have an added dimension: time. These 3D objects transform and change shape over time upon exposure to certain stimuli.

Such behavior can be achieved by using multiple materials in the print, each of which will absorb water at a different rate. Upon exposure to water absorption occurs resulting in the expansion and contraction of different components. If the components are correctly aligned these expansions and contractions give rise to the bending and folding of the overall structure.

The emergence of "4D printing" | Skylar Tibbits

4D Printing: TED | YouTube

Other 4D printers exploit heat as an external stimulus as extreme temperatures are known to alter a materials shape. However, future 4D printed objects may use small changes in temperature or other stimuli to achieve their transformations such as light, pressure or humidity.

Image Credit: MIT/Self-Assembly Lab

Why is 4D Printing Exciting?

Other similar self assembling and shape changing technologies rely on electricity and robotics to achieve their folding and bending, whilst 4D printing can use heat or water to be activated. The fact that 4D printed materials do not rely on electricity to activate their “programmed” folding means that they fit into a number of applications that other similar technologies cannot.

4D printing will also open the door to the printing of complex, multi-component structures which require only a 4D printer and a computer to create. The design opportunities available appear endless.

Why is 4D Printing Not Everywhere?

There are still a number of hurdles that 4D printing must overcome before it achieves its potential as a widespread commercial manufacturing technology.

Currently the process of bending into a new shape introduces strain and reduces the material's mechanical strength making it more susceptible to future damage. The materials can also take a long time to respond to their stimuli resulting in a slow rate of shape changing. These slow transformations can mean 4D printing not as useful in some applications.

4D printed materials can also have problems when reverting back to their original shapes and in many cases the shape change can be permanent and irreversible.

The Self-Assembly Lab

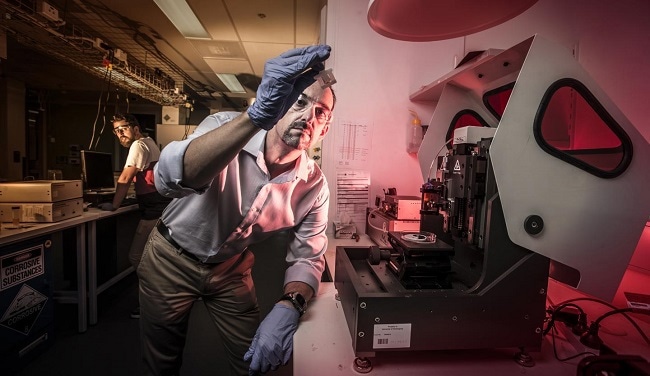

MIT has researched 4D printing through the work and collaboration of Self-Assembly Lab, Stratasys and Autodesk. The project used Stratasys’ Connex multi-material 3D printer technology. This technology allows 3D printing with a variety of different materials.

Using this technology the Self-Assembly Lab have produced a 2D template that folds into a cube when submerged in water.

4D Printing Self Folding Surface Cube HD

4D Printing A Cube: Self-Assembly Lab | YouTube

The Self-Assembly Lab use a Stratasys’ Objet260 Connex1 model printer which has 14 base material options. It allows printing with transparent materials, rubber-like materials, rigid opaque materials and simulated polypropylene materials.

Since 4D printing relies on the varying way materials behave when exposed to the same stimulus the ability to print with several different materials is essential for 4D printed designs.

Self-Regulating Plumbing

MIT is not the only lab to be exploring the world of 4D printing, the ARC Centre of Excellence for Electromaterials Science (ACES) at Wollongong University is also conducting research in the field. ACES is looking into applications in the production of soft robotics for the medical field.

Image Credit: University of Wollongong/Paul Jones

ACE have designed a valve that closes itself when activated by heat. Once printed the valve requires no further activation, meaning it is operational and ready for use without any adjustments. When exposed to hot water the valve activates and begins to shut itself.

This valve is revolutionary as is that it does not require user input to be closed nor does it require electronic sensors and motors. This makes it an incredible tool in the field of medicine as electronic devices are often limited due to their reliance on a power source.

Improving the Print

The team working at Wollongong University in Australia hopes to overcome these obstacles with their 4D printing research.They are using an ionic covalent entanglement (ICE) gel that has proven to be effective at tackling the problems discussed, i.e. irreversibility and strain.

ICE gels use ionic and covalent bonds to link polymers together in order to maximize the strength of the 4D print. The gel’s properties also make it less susceptible to structural mechanical failures like cracking as the it makes up to 20% of the material in the print.

The gel is triggered by a temperature above or equal to 95 ºF (35 ºC) which causes a rapid loss of water content and resulting in the gel to reduce its volume by about half, meaning any attached components will be brought closer together. The researchers have used this volume reduction to create their self adjusting valve.

4D Printing of the Future

Whilst still in its infancy the field of 4D printing is expected to be used extensively in the future, leading MarketsandMarkets to predict that the 4D printing market will reach $63m by 2019 and more than half a billion by 2025.

Image Credit: MIT/Self-Assembly Lab

A lot of excitement surrounds 4D printing technology as a nucleus of creativity. Ideas in the development stage include the development of clothing that responds to environmental stimuli maximize wearer comfort. The idea of 4D printed clothes is being taken further by the military who hope to produce camouflage that actively blends into the surrounding environment.

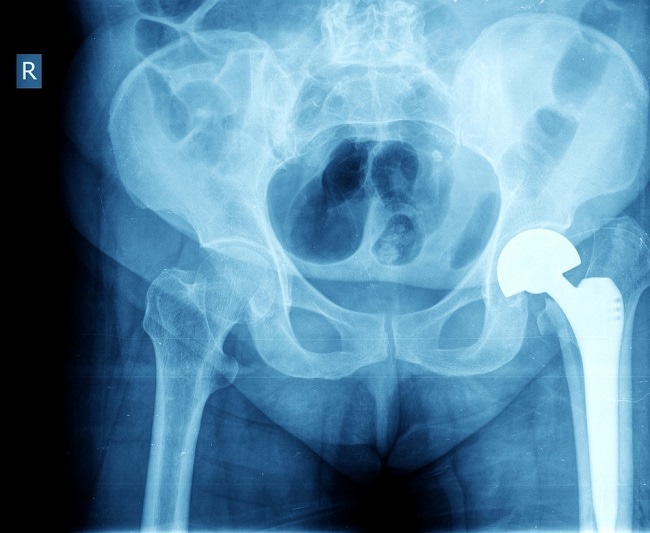

Image Credit: martin81/Shutterstock.com

The medical industry is also expected to make use of 4D printing as shape changing 4D prints are expected to be more compatible with the body than rigid metal supports. The United States Army has already granted $1m to three universities to further research 4D Printing in the aim of developing self assembling weapons and tools, as well as the color-shifting camouflage mentioned previously.

References and Further Reading

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.