The size and shape of printer toner particles can considerably impact the image resolution and efficiency of a printer. The consistency of these particles also influences the distribution of charge the particles hold and, as a consequence, can affect overall image quality.

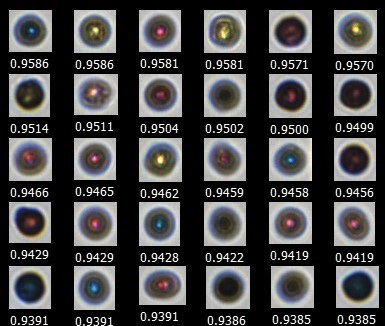

Image characterization can help to determine the size, shape, circularity and material uniformity of printer toner particles during and after production (Fig. 1).

Figure 1. Color printer toner particles imaged by the FlowCam. Circularity value is shown beneath each image. Particles are shown in order of decreasing circularity, where 1 is a perfect circle. Image Credit: Yokogawa Fluid Imaging Technologies, Inc.

This article demonstrates that the FlowCam®, a flow imaging microscope, along with paired image analysis software, VisualSpreadsheet®, can be useful for high-speed quality control characterization of printer toner. The FlowCam is the ideal substitute for aging Sysmex FPIA-3000 systems that are no longer being supported by the manufacturer.

Watch a video: What is Flow Imaging Microscopy?

FlowCam Analysis

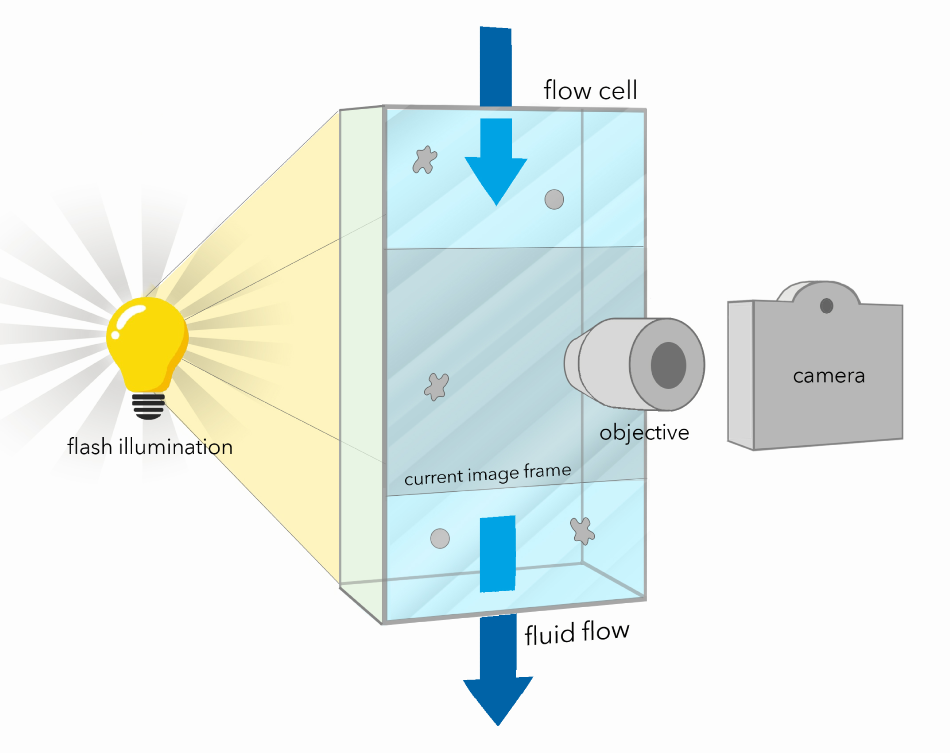

In order to analyze a sample of printer toner using the FlowCam, the toner is mixed with deionized water to create an aqueous slurry. The slurry is then fed into the FlowCam where it is drawn through the flow cell and an image of each singular printer toner particle is captured. VisualSpreadsheet software then compiles a collage of all of the individual particle images from the sample run and measures 40+ properties of the particles from these images (Fig. 1).

Figure 2. A diagram of the flow cell. Flow Imaging Microscopy uses digital images to measure the size and shape of each particle. Image Credit: Yokogawa Fluid Imaging Technologies, Inc.

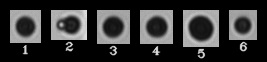

Each particle image collected by VisualSpreadsheet is associated with an ID number and correlated particle property values. The software measures every particle to 4 decimal places for each property value, and these can be exported from VisualSpreadsheet into CSV format for further data manipulation and analysis (Fig. 3 & Table 1).

A software filter was created in VisualSpreadsheet for this analysis to distinguish between printer toner images that meet the given quality parameters from those that do not. This filter was created with an allowed Equavalent Spherical Diameter (ESD) of 4 µm to 8 µm, and an allowed Circularity of 0.8000 to 1.0000, where 1.0000 is a perfect circle/sphere.

Figure 3. Printer toner particles imaged by the FlowCam. Particle ID shown beneath each image correlates with data in Table 1. Image Credit: Yokogawa Fluid Imaging Technologies, Inc.

| Particle ID |

Diameter ESD (µm) |

Circularity |

| 1 |

6.2522 |

1.0000 |

| 2 |

6.6205 |

0.8860 |

| 3 |

6.6205 |

0.9627 |

| 4 |

6.6205 |

0.9405 |

| 5 |

7.9145 |

0.9714 |

| 6 |

5.1755 |

1.0000 |

Table 1. Exported diameter and circularity data for particles in Figure 3. Source: Yokogawa Fluid Imaging Technologies, Inc.

The images and data can be easily sorted to calculate the percentage of particles that meet the parameters specified. The user can also generate a Summary Statistics table that shows selected particle properties that update as the sample runs. This allows for rapid evaluation in real time (Table 2).

| Summary Stats |

Mean |

Minimum |

Maximum |

Std. Dev. |

% CV |

| Circularity |

0.9301 |

0.8000 |

1.0000 |

0.0408 |

4.1781 |

| Diameter (ESD) |

5.8562 |

4.0000 |

8.0000 |

0.9657 |

16.4021 |

Table 2. Summary Statistics calculated by VisualSpreadsheet from a single run of printer toner. Summary statistics are calculated in real time to reflect the analysis. Source: Yokogawa Fluid Imaging Technologies, Inc.

Summary

Image analysis enabled by Flow Imaging Microscopy is crucial to the ability to measure particle circularity, one of the principal properties relevant to quality control analysis in the manufacturing of printer toner. Other high-volume particle analysis techniques are able to determine particle size, but since they assume that all particles are spheres, they do not allow for particle shape analysis. The combination of particle size and shape monitoring, as made possible using the FlowCam, enhances the quality control process essential to printer toner manufacturers.

Implementing a QA/QC filter can help assess the general quality of each analyzed sample. The FlowCam is well adapted for a broad range of applications that necessitate rapid, quantitative results. The instrument has an intuitive design that enables an operator to conduct on-site testing of a product with conformational data, statistics and reporting.

This information has been sourced, reviewed and adapted from materials provided by Yokogawa Fluid Imaging Technologies, Inc.

For more information on this source, please visit fluidimaging.com.