Sponsored by Tough TechMar 14 2023Reviewed by Louis Castel

Tough Tech can handle heavy transportation challenges. This article details the most recent installation.

The first windmill in Holland was built in 1221, and the country still has the world’s tallest windmill, standing at 245 m (803 ft). The scale of the windmill can be visualized by comparing some of its components. Each blade is 100 m (328 ft) long, roughly the length of a football field. The tower is taller than Big Ben, the Tower of Pisa, and the Arc de Triomphe combined.

Image Credit: Tough Tech Ltd

The parts that make up wind turbines located all over the world, such as all large-scale machinery, must still be shipped securely by road and often to remote locations to be erected.

Image Credit: Tough Tech Ltd

The Latest Challenge—Pushing the TPMS Boundary

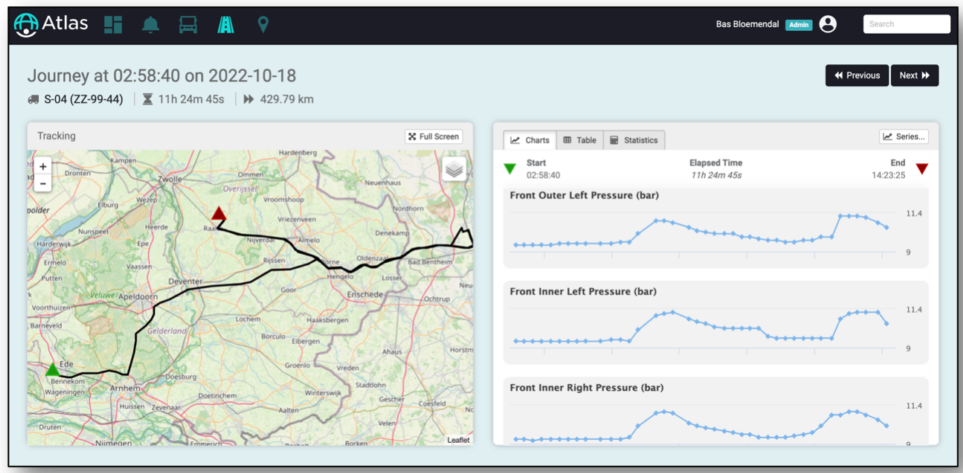

A demanding 55 m wheelbase, trailer, and prime mover with 40 tires on the trailer alone. Even when the trailer is uncoupled and unpowered, it provides linked real-time 24/7 TPMS as well as tracking, security, and many other functions.

The solution had to interact with all relevant safety personnel linked to the vehicle’s and its load’s health by providing data visibility via the Web App and Mobile App, including current tire status. Early intervention for tire and vehicle issues is critical to ensuring the success of the stakeholders responsible for the operation’s effectiveness and security; that of transporting heavy loads across the country boundaries.

To effectively manage efficiencies, safety, and compliance, the customer prioritized the ability to monitor the health of the vehicle and trailer, including the tires—before, during, and after the journey. The digitalization of the vehicles provides real-time tire insight and eliminates the uncertainty associated with a “ghost fleet” operation.

Rich Heritage

For nearly five years, ATLAS has repeatedly demonstrated, with the first-generation classic product, that the ATLAS solution is simple to install, simple to use, and inexpensive, while ensuring that the user has access to precise and clean data. The data belongs to the customer, and they require it to efficiently manage their resources.

ATLAS recently released a second-generation ATLAS solution. This provides much more than TPMS and allows monitoring of multiple tires whether the trailer is powered or not.

Pushing the TPMS Boundary

The Dutch hauler had been unable to find a connected TPMS solution for many years that would deliver the functionality previously mentioned alongside the scale of the technical challenges for each of their prime movers and trailers, including:

- Length: Wheelbase Length 55.3 m

- Axles: Trailer Axles 10

- Tires: Trailer Wheels 40

Other more practical challenges, such as access to the tires, had to be looked at in addition to the scale of size. How were tires checked before, during, and after the delivery of the load? Even though tires contribute to the operation’s success, it is extremely difficult to complete this task safely.

Tires are built to carry a load at a specific speed. Tire pressure must be set at the manufacturer’s recommended pressure to maximize tire life, reduce fuel consumption, and allow the load to be carried safely.

In a multi-axle, twin-wheeled, articulated heavy load trailer or a self-propelled modular trailer (SPMT), the inner wheels are extremely difficult to access, which poses a significant safety risk when the trailer is loaded and moving. This customer was no different from any other. Everyone is concerned about the rising cost of assets, such as fuel and tires.

TPMS Research

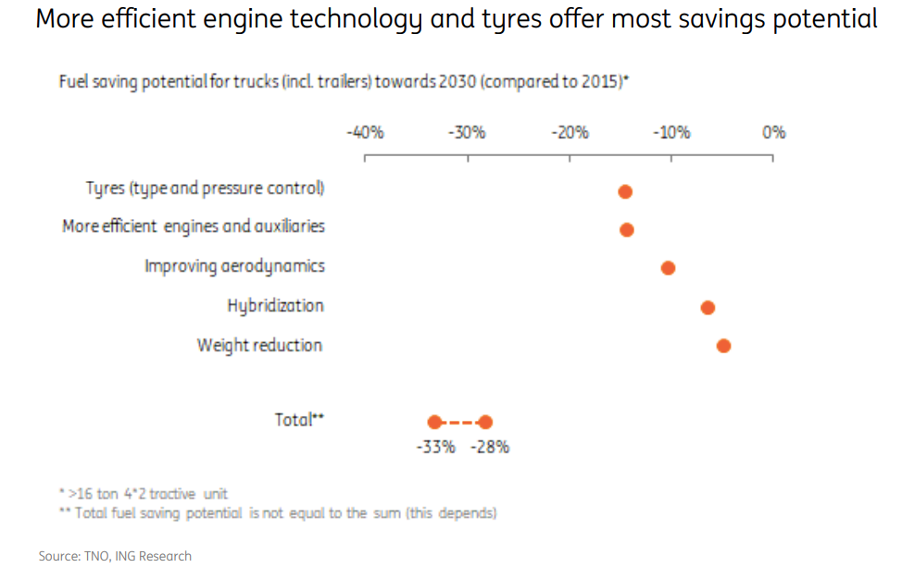

The latest ING research report emphasized the significance of tire pressures as the number one solution for how haulers can save fuel. It is also the most straightforward to address. Other leading solutions outlined in the report included aero dynamics and engine management, both of which require substantial investment.

Regular users of tires for their fleet, especially those in technical sizes, will have noticed the longer delivery times. This is also leading to more situations in which fleet operators must look outside of their preferred brand, even for common sizes.

Image Credit: Tough Tech Ltd

This creates uncertainty for the hauler regarding load and tire performance, especially when performing heavy haulage operations. Some specialist haulage and load operators, for example, are demanding higher increases in tire pressure for load carrying (while trading off speed). Certain tire manufacturers can meet this demand and provide tires that can meet the load’s requirements.

What is missing is the technology that the operator requires to observe these incredible pressure and tire temperatures. If the tires are not available and substitutes are used, the ability to interact with the vehicle and gain insight into its health (including tire temperature and pressures) becomes more important to the operator.

Image Credit: Tough Tech Ltd

TPMS Success

Prevailing data shows that as speed increases, tire pressures can fluctuate by 20–30 psi in a single journey. The need for better insights into tire performance while on the road is more important than ever. The cost of a tire-related breakdown for these heavy haulage companies is evaluated not only financially, but also in their ability to deliver the load to the client’s expectations. Above all, it was delivered safely.

All the challenges mentioned were especially relevant to this fleet. The ATLAS solution was proposed to the customer. It is simple to set up via an app, allowing them to quickly connect and monitor the health of their fleet on every journey, no matter how long. It will provide a 24/7 insight and interactive solution for monitoring tire health and the security/location of any of the fleet’s 40-wheeled trailers or prime movers, even when uncoupled and unpowered.

Fleet Digitization

A potent and dependable connected IOT telematics system built on connected real-time TPMS.

Simple to install and use, and all at a very reasonable price for operators.

Image Credit: Tough Tech Ltd

The latest Atlas generation allows the operator to track key assets and the health of their vehicle, trailer, or machine on every journey.

Image Credit: Tough Tech Ltd

At the same time, the customer needed integration of the ATLAS solution into their back-office system. The ATLAS system is fully customizable and can be translated into multiple languages for the operator’s convenience.

Pushing the TPMS Boundary

ATLAS technology is continually pushing the limits of TPMS technology. “How many tires will one ATLAS unit cover?” is the most prevalent question which is generally met with the following response: “I don't know, we have yet to find the constraints on wheel positions for the unit,” states Gary Brierley.

Needless to say, ATLAS is always up for the challenge of determining how many.

One thing about working with Dutch customers is their pragmatic outlook to any challenge that is swiftly followed by quoting some “well-known Dutch phrase.”

“Zonder wind kan een molen niet draaien” (a windmill does not work without wind).

Simply put, something (e.g. operational efficiency) always requires “something” to work. Humans require food, water, and oxygen to function, and a bank is nothing more than a fancy waiting room without money.

ATLAS and an operator ready to embrace new technology to improve operating effectiveness are that “something.”

Image Credit: Tough Tech Ltd

The customer is empowering their entire fleet with the ATLAS solution in a matter of days.

ATLAS successfully addressed the challenges of scale, number of wheel positions, ease of fitment, and ease of use (which included full training and after-sales service from the Dutch distributor), all at a very low cost.

This information has been sourced, reviewed and adapted from materials provided by Tough Tech.

For more information on this source, please visit Tough Tech.