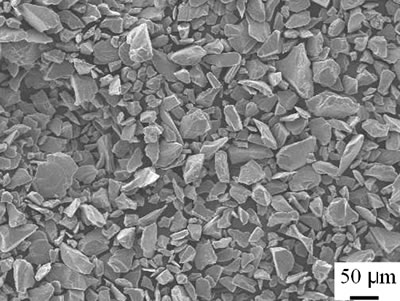

Introduction Thermal spray technology is gaining an increasing interest because it offers the possibility to prepare large active coatings, which can exhibit an excellent adhesion to substrates with rather complex shapes [1]. Indeed, the principle behind plasma spray is to melt material feedstock (commonly powder) and to accelerate the molten particles until impact on a substrate where rapid solidification and deposit buildup occur. The microstructure and the properties of plasma spray coatings depend not only on the characteristics of the feeding powder, but are also markedly influenced by various process parameters. Among all parameters at plasma spraying, spraying power and distance are the two main and important factors for the microstructure and the properties of coatings. Plasma sprayed TiO2 coating possesses high hardness, high density, good ductility and good adhesive bonding to substrate [2, 3]. The coating has been used as a material for light bearings in applications such as shaft bearing sleeves and pump seals to resist wear [4]. In this work, five TiO2 coatings were deposited with altered spraying powers and distances while the other spray parameters were fixed. The effects of the two plasma spraying parameters on phase content, powder deposition efficiency, microstructure including roughness and porosity, and microhardness for these coatings are investigated. Experimental Commercial TiO2 powder (METCO 102, Sulzer Metco Inc., U.S.A) was used to deposit coating samples. The powders obtained from sintering and crushing processes are irregular and angular with the grain size of about 20-50 µm, which is shown in Figure 1. |

| | Figure 1. SEM micrograph of TiO2 powders. | Spraying was performed on an unheated substrate under atmospheric conditions using the Metco A-2000 atmospheric plasma spraying equipment with F4-MB plasma gun (Sulzer Metco AG, Switzerland). The powders were fed with a Twin-System 10-V (Plasma-Technik AG, Switzerland). The thickness of as-sprayed coatings was about 350-420 µm. The stainless steel substrates (50 mm×20 mm×2 mm) were degreased ultrasonically in acetone and grit-blasted with alumina abrasive before the spraying. Five coatings were deposited with different spraying powers and distances (Table 1), while the other deposition parameters were maintained as constant as possible. The spraying power was modulated by changing the flow of H2 gas and the spraying current. Table 1. Spraying powers and distances for TiO2 coatings. | | | 1 | 120 | 40.2 | | 2 | 120 | 42.6 | | 3 | 100 | 42.6 | The crystalline structures of TiO2 coatings were investigated using a x-ray diffractometer (Rint 2000, Rigaku, Tokyo, Japan) operating with Cu Kα (λ= 0.154056nm) radiation. The analyzed range of the diffraction angle 2θ was between 10° and 90° by a step width of 0.04°. The morphology of the starting powder was observed by scanning electron microscopy (SEM; JSM 6400, JEOL, Tokyo, Japan), while the surface morphologies of these coatings were obtained by optical microscopy (Olympus OLS 1100, Olympus, Japan). Standard metallographic procedures were used in the preparation of optical samples. The porosity was determined by image analysis technique due to the principle of gray value analysis. The surface roughness of coating was measured as Ra with a Form Talysurf Plus surface roughness tester (Rank Taylor Hobson, Leicester, England). Vickers microhardness tests were performed on polished surfaces of the TiO2 coatings with a 2.94 N normal load and a dwell time of 15 s. All the reported microhardness values are mean of 20 indentations. To avoid the effect of stress field, the distance between two indentations was kept greater than three times the indentation diagonal [5]. Results and Discussion Effect of Spraying Conditions on Phase Content An x-ray phase analysis carried out on these coatings is shown in Figure 2. All of the coatings show a predominant rutile stable phase structure as a result of rapid solidification. At the same time, there is a small amount of anatase phase content retained for the coating sprayed with lowest spraying power, as Anatase converts to rutile at temperatures of 400-1200℃, and powder begin to transform to rutile at temperature > 900℃ [6]. The results in this study probably imply that TiO2 feedstocks were molten and only a small amount of original anatase phase appears when the spraying power was lower. At the same time, the metastable anatase phase can appear from the liquid state achieved by the granules during their flight inside the plasma jet [7], the longer distance may be the reason for the existence of anatase phase in sample 5. The x-ray diffraction patterns indicate that the change on spraying power and distance have influence on the crystalline structure of TiO2 coating. |

| | Figure 2. XRD spectra of TiO2 coatings. | Effect of Spraying Conditions on Deposition Efficiency Deposition efficiency is defined as the ratio of the coating weight to the weight of total feedstock. Figure 3 shows the variation of deposition efficiencies of TiO2 powders with the spraying power (Figure 3a) and the spraying distance (Figure 3b). The results reveal that the deposition efficiency of TiO2 coatings depend on the two parameters. Within the investigated scope of spraying parameters, the deposition efficiency is decreased from 65.1% to 54.7% with the decrease in the spraying power and the increase in the spraying distance. The deposition efficiency was 56.3% at the spraying power of 40.2 kW and then reached the largest value (65.1%) when the spraying power is 43.8 kW. |

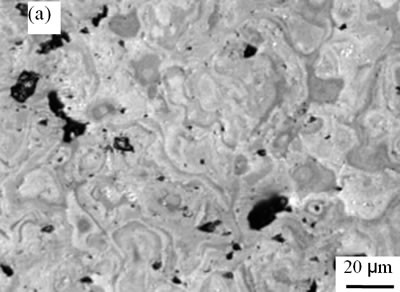

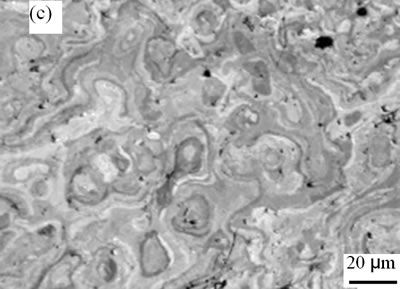

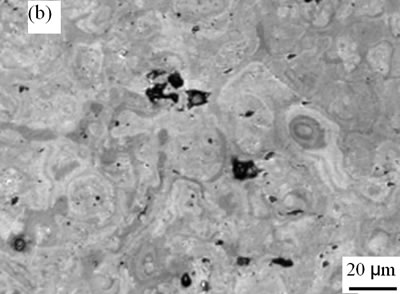

| | Figure 3. Influence of spraying power (a) and distance (b) on the deposition efficiency of TiO2 powder. | In general, the larger the spraying power and the shorter the spraying distance are, the higher the deposition efficiency is. It was metioned above that the molten degree of conventional powders depended strongly on the spraying power. During the spraying, unmolten powders fell out of the substrate, so the largest deposition efficiency (65.1%) appeared at the spraying power of 43.8 kW. Also, the deposition efficiencies were improved when spraying distance decreased to 100 mm due to higher flight velocity of powders sprayed. Effect of Spraying Conditions on Microstructure Figure 4 shows the optical micrographs of TiO2 coatings deposited under different values of the spraying power. It can be seen that the microstructure is apparently related to the spraying power. When the spraying power is the lowest, the sizes of pores are the largest, which can be found in Figure 4(a). On the contrary, samples deposited with higher spraying powers have better microstructure, which can be seen in Figure 4(b) and Figure 4(c). |

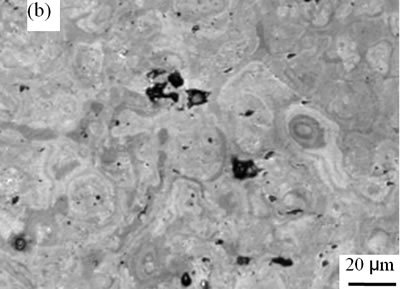

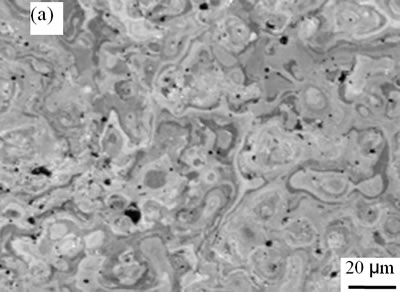

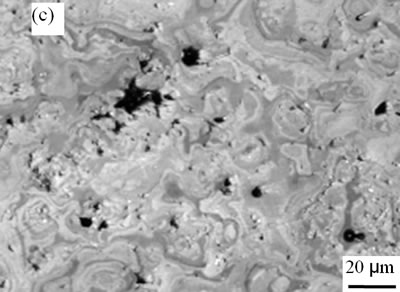

| | Figure 4. The surface morphologies of plasma sprayed TiO2 coatings deposited under spraying distance 120mm and different spraying powers; (a) 40.2 kW, (b) 42.6 kW and (c) 43.8 kW. | The spraying distance influence apparently the microstructure of TiO2 coatings too, which is shown in Figure 5. The sizes of pores increase with the increasing of spraying distance. Figure 6 shows the influence of spraying power (a) and spraying distance (b) on porosity of these TiO2 coatings. The porosity is lower when the spraying power is higher or spraying distance is shorter. |

| | Figure 5. The surface morphologies of plasma sprayed TiO2 coatings deposited under spraying power 42.6 kW and different spraying distances; (a) 100 mm, (b) 120 mm and (c) 140 mm. | |

| | | Figure 6. Influence of spraying power (a) and distance (b) on porosity of plasma sprayed TiO2 coatings. | | The reason for the difference in microstructure is the difference in the molten degree of the TiO2 powders during the plasma process and the velocity of molten TiO2 powders when they impact the substrate. The coatings are formed by the piling of lamella as individual particles impact, deform and then rapidly freeze. A high level of melting and a higher particle velocity before impact may be expected to give better deformation of the drop, and lead to better bonding between lamella resulting in lower porosity. When the power is increased, all the particles are almost completely molten when they reach the substrate, thus they form the splats, which can pack densely. On the contrary, when the plasma power is low the powder is less molten, and most of the granules fall in pieces when they reach the substrate leading to unmelted small particles. The spraying distance is closely related to the velocity of molten powders when these impact the target substrate. Because the velocity of molten powders from the plasma flow at the spraying distance of 100 mm is higher, less smaller size pores were found as shown in Figure 5(a). In turn, some larger pores were observed clearly in the as-sprayed TiO2 coating deposited at longer spraying distance such as in the sample shown in Figure 5(c). The result stemmed from the combining effects of environmental cooling and long-distance flight. It is to be noted only a little difference on the surface roughness for TiO2 coatings appear when they were deposited with different spraying powers, while apparent decrease in surface roughness appears when spraying distance increase from 100 mm to 140 mm, which is shown in Figure 7. This decrease is attributed to lower velocity molten powers achieved. |

| | Figure 7. Influence of spraying power (a) and distance (b) on roughness of plasma sprayed TiO2 coatings. | Figure 8 shows that the porosity is more important when the roughness is lower. This behavior is probably due to the fact, that small particles could be more densely packed together in the coating resulting in low roughness. This result is the same as Berger-Keller’s [7]. |

| | Figure 8. Relationship between roughness and porosity of plasma sprayed TiO2 coatings. | Effect of Spraying Conditions on Microhardness of as-Sprayed Coatings A similar influence is noted on the Vickers microhardness of these TiO2 coatings. Figure 9 shows the microhardness values of TiO2 coatings sprayed under different parameters. It seems that a corresponding relationship exists between the microstructure and microhardness of TiO2 coating. The lower the porosity is, higher the microhardness is. This can be explained by principle for microhardness measurements. During the indentation process, a complex elastic-plastic field is formed beneath the indentation. Porosity tends to reduce the effective area supporting the load and is detrimental to strength. When porosity or an equivalent defect is present in a sample, the load bearing area is reduced. It can be safely assumed that the defective region will yield first, thereby concentrating the strain. However, voids create a multiaxial stress state and cause local strain concentration in their vicinity [8]. It is clear from Figure 9 that an increase in porosity content decreases the microhardness of TiO2 coatings. |

| | Figure 9. Influence of spraying power (a) and distance (b) on mircrohardness of plasma sprayed TiO2 coatings. | As porosity of the TiO2 coating depends on spraying power and distance, the two parameters can influence microhardness of TiO2 coating. The coating deposited with the higher spraying power and shorter spraying distance has a higher microhardness. Conclusions All results indicate, that phase content, deposition efficiency, microstructure such as porosity and roughness, and microhardness for plasma sprayed TiO2 coating depend on spraying power and distance. It is clear that all the coating process variables and the resulting microstructures strongly affect the mechanical properties of the coating. Acknowledgements This work was supported under the program of the ITEP 1005583 in Korea. The authors would like to thank Mr.Young-Durk Park, manager of Technology Innovation Center in Sun Moon University for his help on optical micrographs. References 1. H. R. Khan and H. Frey, “R. f. plasma spray deposition of LaMOx (M Co, Mn, Ni) films and the investigations of structure, morphology and the catalytic oxidation of CO and C3H8”, J. Alloys Compounds, 190 (1993) 209-217. 2. Yinglong Wang, Yuansheng Jin and Shizhu Wen, “The inspection of the sliding surface and subsurface of plasma-sprayed ceramic coatings using scanning acoustic microscopy, Wear, 134 (1989) 399-411. 3. W.W. Dai, C.X. Ding, J.F. Li, Y.F. Zhang and P.Y. Zhang, “Wear mechanism of plasma-sprayed TiO2 coating against stainless steel”, Wear, 196 (1996) 238-242. 4. Mel I. Mendelson, “Theoretical evaluation of wear in plasma-sprayed TiO2 against grey cast iron”, Wear, 50 (1978) 71-83. 5. S. Leigh, A. Lin and C. C. Berndt, “Elastic response of thermal spray deposits under indentation tests“, J. Am. Ceram. Soc., 80 [8] (1997) 2093-2099. 6. P. I. Gouma and M. J. Mills, “Anatase-to-rutile transformation in powders“, J. Am. Ceram. Soc., 83 [3] (2001) 619-622. 7. N. Berger-Keller, G. Bertrand, C. Filiatre, C. Meunier and C. Coddet, “Microstructure of plasma-sprayed titania coatings deposited from spray-dried powder“, Surf. Coat. Technol., 168 (2003) 281-290. 8. C. H. Cáceres and B. I. Selling, “Casting defects and the tensile properties of an Al-Si-Mg alloy“, Mater. Sci. Eng., A 220 (1996) 109-116. Contact Details |