|

Friction welding has been used by the automotive industry for decades in the manufacture of a range of components. The process is attractive for several reasons:

• The friction heating is generated locally, so there is no widespread softening of the assembly

• The weld is formed across the entire cross-sectional area of the interface in a single shot process

• The technique is capable of joining dissimilar materials

• The process is completed in a few seconds with very high reproducibility - an essential requirement for a mass production industry.

Now, a new variant from the same stable of friction processes, known as ‘friction stir welding’, is finding increasing use in the fabrication of automotive components, even though its processing speed is not yet as rapid.

How does Friction Welding Work?

Traditionally, friction welding is carried out by moving one component relative to the other along a common interface, while applying a compressive force across the joint. The friction heating generated at the interface softens both components, and when they become plasticised the interface material is extruded out of the edges of the joint so that clean material from each component is left along the original interface. The relative motion is then stopped, and a higher final compressive force may be applied before the joint is allowed to cool. The key to friction welding is that no molten material is generated, the weld being formed in the solid state.

Rotary Friction Welding

Rotary friction welding, in which one component is rotated against the other, is the most commonly used of the processes, and many carbon steel vehicle axles and sub-axles are assembled in this way. The process is also used to fabricate suspension rods, steering columns, gear box forks and driveshafts, as well as engine valves, in which the ability to join dissimilar materials means that the valve stem and head can be made of materials suited to their different duty cycles in service, figure 1.

|

|

|

Figure 1. Friction welded parts including valves and a gearbox fork.

|

Linear Friction Welding

Linear friction welding, (so named because the relative motion is linear across the interface, rather than rotary), is already used to join blades onto discs in the aeroengine industry. Lower cost linear friction welding machines are now being developed for automotive applications, such as the fabrication of brake discs, wheel rims and engine parts.

Friction Stir Welding

Friction stir welding also produces a plasticised region of material, but in a different manner. A non-consumable rotating tool is pushed into the materials to be welded and then the central pin, or probe, followed by the shoulder, is brought into contact with the two parts to be joined, figure 2. The rotation of the tool heats up and plasticises the materials it is in contact with and, as the tool moves along the joint line, material from the front of the tool is swept around this plasticised annulus to the rear, so eliminating the interface.

|

|

|

Figure 2. Schematic of the friction stir welding process.

|

Advantages of Friction Stir Welding

The process was patented in December 1991 and the first applications have been in aluminium fabrications. The weld quality is excellent, with none of the porosity that can arise in fusion welding, and the mechanical properties are at least as good as the best achievable by fusion welding. The process is environmentally friendly, because no fumes or spatter are generated, and there is no arc glare or reflected laser beams with which to contend.

Another major advantage is that, by avoiding the creation of a molten pool which shrinks significantly on resolidification, the distortion after welding and the residual stresses are low. With regard to joint fit up, the process can accommodate a gap of up to 10% of the material thickness without impairing the quality of the resulting weld. As far as the rate of processing is concerned, for materials of 2mm thickness welding speeds of up to 2m.min-1 can be achieved, and for 5mm thickness up to 0.75m.min-1. Recent tool developments are confidently expected to improve on these figures.

Materials Suitability

Friction stir welding has been used to weld all wrought aluminium alloys, across the 2xxx, 5xxx, 6xxx and 7xxx series of alloys, some of which are bordering on being classed as virtually unweldable by fusion welding techniques. The process can also weld dissimilar aluminium alloys, whereas fusion welding may result in the alloying elements from the different alloys interacting to form deleterious intermetallics through precipitation during solidification from the molten weld pool.

Friction stir welding can also make hybrid components by joining dissimilar materials such as aluminium and magnesium alloys. The thicknesses of 6082-T6 that have so far been weld have ranged from 1.2mm to 50mm in a single pass, to more than 75mm when welding from both sides. Welds have also been made in pressure die cast aluminium material without any problems from pockets of entrapped high pressure gas, which would violently disrupt a molten weld pool encountering them.

Applications

The original application for friction stir welding was the welding of long lengths of material in the aerospace, shipbuilding and railway industries. Examples include large fuel tanks and other containers for space launch vehicles, cargo decks for high-speed ferries, and roofs for railway carriages.

Automotive Applications

In the automotive sector the drive to build more fuel efficient vehicles has led to the increased use of aluminium in an effort save weight, which also improves recyclability when the vehicles a scrapped. Friction stir welding is being use increasingly to replace fusion welding techniques when alumnium alloys are involve the main advantage being low distortion and the ability to weld awkward materials material combination The process has already been applied to the manufacture of tail light panels by Marine Aluminium Aanensen in Norway, and SAPA in Sweden have recently taken delivery of a new friction stir welding machine from ESAB for the production of automotive parts. However, the technique has not yet been adopted in production for the fabrication of aluminium tanks for bulk road transport of liquids and powders.

With regard to smaller components, automotive suspension arms have been made in Japan by Showa Aluminium and Tokai Rubber, applying the formerly large-scale process to components with diameters as small as 20-30mm. Wheel assemblies using two aluminium alloys have been made by Hydro Aluminium in Norway, figure 3, in which the butt or lap welds can be fabricated in wrought and/or cast materials.

|

|

|

Figure 3. A friction stir welded aluminium wheel.

|

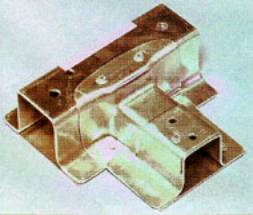

Prototype tailor welded blanks, in which dissimilar thicknesses of material are welded together, are also being made by friction stir welding, for example in the inner door panels of aluminium cars. The AO Smith Corporation in the USA has developed a prototype aluminium friction stir welded engine cradle, while in the same country Tower Automotive has produced the Simulform connector for the fabrication of chassis members and space frames, figure 4. Friction stir welding has also been used to weld lightweight panels made of plastic foam sandwiched between two sheets of aluminium, for which any fusion welding technique would encounter serious problems because of the much higher temperatures involved. Foamed aluminium itself has been friction stir welded too. Other current applications under review include the bodies and floors of coaches and buses, military bridge-laying vehicles (and bridges/pontoons), and waste skips.

|

|

|

Figure 4. A friction stir welded aluminium connector.

|

Applications for the Future

Such has been the interest in friction stir welding, which was patented no so long ago, that considerable effort is being made in transferring the technological benefits from aluminium and magnesium to higher temperature materials such as copper, titanium and steels. TWI has two projects in conjunction with several industrial users to develop the friction stir welding of titanium and steels.

Another project on the friction stir welding of aluminium alloys involving industrial firms has also recently started. This is assessing innovative weld joint geometries for friction stir welding aluminium extrusions and wrought alloys together in transport structures. This will take the process beyond its current use of mainly simple butt and lap joint configurations and make it a much more flexible fabrication process. Other firms who are interested in the benefits of adopting this new technology can join these consortia.

Summary

In the new millennium there is no doubt that the automotive sector will find an increasing number of uses for this process as its cost-effectiveness and ability to weld dissimilar material combinations with minimal distortion is more widely appreciated.

The message for lightweight vehicle design engineers is that they can also specify alloys in welded components and structures that they had previously shied away from using because of their inherent fusion welding problems.

|