Anton Paar has launched two advanced models of the MCR Evolution series — the MCR 702e MultiDrive and MCR 702e Space MultiDrive. These are the most versatile commercially available rheometers.

Apart from all standard rheological test modes, it is possible to load additional lower drive units. This implies that the user can perform the rheological test using two torque transducers and drive units simultaneously. This offers multiple possibilities for the research.

The system has no limitations concerning measuring systems, accessories, used test modes, temperature devices and measurement accuracy. Furthermore, MCR 702e Space MultiDrive offers the highest working space to enable simple working with accessories and additional tools. This makes it the system of choice to envelop all possible rheological applications for now and for future requirements.

MCR 702e MultiDrive

- Includes one rheometer, two driving units and all working modes

- The system is a high-end rheometer for complicated rheological research

- Available with 200+ accessories for endless possibilities in research and development

- Ready for DMA in tension, torsion, compression or bending modes

MCR 702e Space MultiDrive

- Maximum working space enables a simple combination with additional optical or mechanical setups, for example, a confocal microscope

- The rheometer can perform sophisticated rheological research and Dynamic Mechanical Analysis

- Designed to work in a glovebox even in an inert gas atmosphere

Key Features

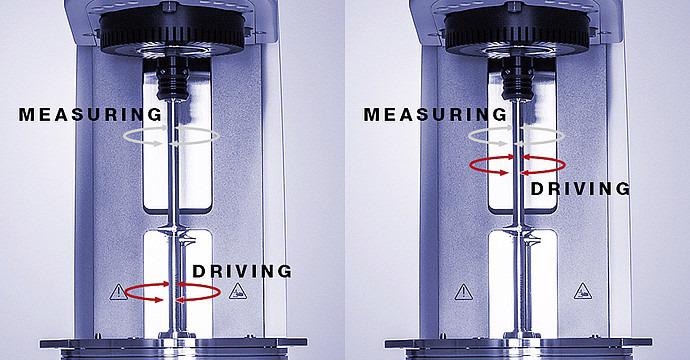

One Rheometer, All Rheological Working Modes

The combination of two air-bearing-supported rotational drive units supports the user to execute rheological measurements in Combined Motor Transducer (CMT) mode and the Separate Motor Transducer (SMT) mode. The use of the single air-bearing-supported EC motor in the CMT mode helps make the most of the motor’s real-time position control (TruStrain™) and carry out “classic” stress-controlled tests.

The SMT mode involves operating one motor solely as a torque transducer, while the other motor is only used as a drive unit, to obtain the purest rheological results even in the transient regime of the measurement (for example, stress relaxation, start-up shear) and over a wide array of amplitude and frequency in oscillatory measurements.

Thanks to all the working modes of MCR 702e MultiDrive and MCR 702e Space MultiDrive, these instruments complete the successful MCR series and contribute to turning the MCR rheometers into the most reliable instruments in scientific rheological investigations.

Image Credit: Anton Paar GmbH

Push Back the Limits of Material Characterization with Counter-Movement Mode

In the counter-movement mode, both air-bearing-supported EC motors are used as drive units and as torque transducers. Both the motors can be easily set to move in opposite directions for making a fixed stagnation plane in a sample for advanced material structure analysis under shear using the microscope.

This mode is also employed with a universal extension fixture for extension tests ranging to the lowest measured torques. When it comes to speed, the counter-movement mode just “doubles the score,” reaching a maximum speed difference of 6000 rpm, which remarkably widens the shear range for high shear applications.

Image Credit: Anton Paar GmbH

Ready for DMA in Torsion, Tension, Bending, Compression and More

An additional lower linear drive can be inserted instead of the lower rotational drive to perform DMA in bending or compression mode using measuring systems like the cantilever, three-point-bending or parallel plates.

Additionally, together with geometrics for films, fibers and rectangular samples, the linear drive can be employed to perform DMA in tension while the upper rotational drive can be employed to execute DMA in torsion both within a single test definition.

The linear drive also has the ability to perform thermomechanical analysis, creep and creep recovery tests and relaxation tests.

Image Credit: Anton Paar GmbH

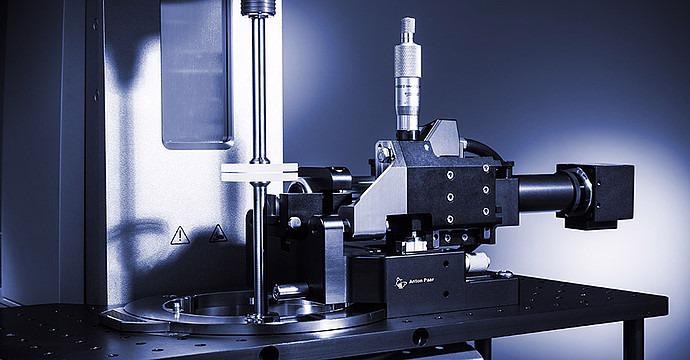

The Best now Better: The Device for Applications that were Previously Unthinkable

The new MCR 702e Space MultiDrive has been engineered to offer an exclusive maximized workspace below the rheometer support plate and on both sides of the instrument. This enables easy installation of accessories and also easy integration with additional external setups ideal for advanced material characterization.

For example, MCR 702e Space MultiDrive enables users to integrate confocal microscopy with rheology. Furthermore, the separate electronics box of the rheometer enables the rheometer to be set up in a compact space or in a laboratory glovebox, even when using inert gas (nitrogen, argon) atmosphere, for example, for high-temperature measurements on samples with a specific hazard level.

Image Credit: Anton Paar GmbH

Measure and Control the Temperature Where it Matters

The system enables the control of the greatest effect of all, that is, the temperature, by using highly accurate temperature control units in association with innovative optoelectronic technology from Anton Paar.

The technology facilitates contact-free transmission based on light emission and photovoltaic effect. The feature enables temperature determination without impacting the torque sensitivity in Separate Motor Transducer (SMT) mode, including counter-movement mode.

The straightforward positioning of the sensor in the measuring system is very close to the sample, about 1 mm apart, lowering the possible offsets between the sample temperature and the temperature measured at the sensor. This facilitates precise determination of the sample temperature even during step or ramp-like temperature changes.

Image Credit: Anton Paar GmbH

More than 200 Accessories and Smart Features to Fit all of the Users’ Applications

MCR 702e MultiDrive and MCR 702e Space MultiDrive are all set to be loaded with any measuring system, temperature device and/or application-specific accessory known from the Anton Paar MCR series to perform regular and advanced rheological analyses of the sample.

The patented Toolmaster™ feature automates recognition and configuration of all connected devices and measuring systems. Furthermore, the QuickConnect function facilitates the single-handed connection of the measuring systems. Both features ensure the highest flexibility and minimum work required to suit the configuration to the user’s needs.

Image Credit: Anton Paar GmbH

Technical Specifications

Source: Anton Paar GmbH

| |

|

MCR 702e MultiDrive

MCR 702e Space MultiDrive |

| Technical Data |

Unit |

Configuration with 1 EC motor |

Configuration with 2 EC motors |

| Bearing design |

- |

Air, fine-pored carbon |

| Motor design |

- |

Electronically Commutated (EC) - Permanent Magnet Synchronous Motor |

| Displacement transducer design |

- |

High-resolution optical encoder |

Normal force measurement design

(US Pat. 6167752, 1996) |

- |

360 ° capacitive sensor, non-contacting, fully integrated in bearing |

| Active thermal management of bearing and normal force sensor |

- |

Yes |

Yes |

| Working modes |

- |

Combined Motor Transducer (CMT) |

Separate Motor Transducer (SMT),

Counter Movement [1] |

| Minimum torque (rotation) |

nNm |

1 |

1 |

| Minimum torque (oscillation) |

nNm |

0.5 |

0.5 |

| Maximum torque |

mNm |

230 |

230 |

| Minimum angular deflection (set value) |

µrad |

0.05 |

0.05 |

| Maximum angular deflection (set value) |

µrad |

∞ |

∞ |

| Minimum angular velocity [2] |

rad/s |

0 |

0 |

Maximum angular velocity

Maximum speed |

rad/s

1/min |

314

3000 |

628

6000 |

| Minimum angular frequency [3] |

rad/s |

10-7 |

10-7 |

Maximum angular frequency [4]

Maximum frequency |

rad/s

Hz |

628

100 |

628

100 |

| Normal force range |

N |

-50 to 50 |

-50 to 50 |

| With Exposed Support Plate (WESP / Space) [5] |

- |

Yes |

Yes |

| Dimensions (W x H x D) |

mm |

444 x 753 x 586

Space:

212 x 767 x 554 |

444 x 753 x 586

Space:

212 x 767 x 554 |

| Weight |

kg |

48

Space:

51 |

58

Space:

61 |

| Additional Device Features |

Device display with remote control of software

(decoupled from measuring sensor for mechanical and electromagnetic interference prevention) |

- |

Yes |

Yes |

| Direct strain/stress controller |

- |

Yes |

Yes |

TruRate™ / TruStrain™

(sample adaptive controller) |

- |

Yes |

Yes |

| Raw data (LAOS, waveform) |

- |

Yes |

Yes |

| Normal force profiles (set and read) |

- |

Yes |

Yes |

| Velocity profiles, tack, squeeze |

- |

Yes |

Yes |

| Automatic gap control/setting (AGC/AGS) |

- |

Yes |

Yes |

| Electronic trim lock for measuring geometry |

- |

Yes |

Yes |

| Fully automatic temperature calibration |

- |

Yes |

Yes |

TruGap™

(permanent control of the real measuring gap)

(US Pat. 6499336, 2000) |

- |

Optional |

Optional |

T-Ready™ [6]

(detection of sample temperature equilibrium time)

(US Pat. 8904852, 2011) |

- |

Yes |

Yes |

Toolmaster™

(measuring geometries and accessories, storing of zero-gap)

(US Pat. 7275419, 2004) |

- |

Yes |

Yes |

QuickConnect Coupling for measuring geometries

(one-hand operation, screwless) |

- |

Yes |

Yes |

Trimming mirror

(360° blind sample spot prevention) |

- |

Yes |

Yes |

Three-point support of device

(three robust feet for tool-free one hand alignment) |

- |

Yes |

Yes |

Three-point support for mounting of measuring cells

(wobble prevention, no misalignment after changing of cells) |

- |

Yes |

Yes |

| Maximum temperature range |

°C |

-160 to +1000 |

-160 to +600 (950 [7]) |

| Maximum pressure range |

bar |

up to 1000 |

n/a |

| Ready for DMA in torsion and tension |

- |

Yes |

Yes |

Ready for Linear Drive

(DMA in tension, bending and compression)

(US Pat. 9574983, 2015) |

- |

Yes |

Yes |

| Ready for tribology |

- |

Yes |

Yes |

| Ready for powder flow and shear rheology |

- |

Yes |

Yes |

[1] US Pat. 8453496

[2] In controlled shear stress (CSS) mode. In controlled shear rate (CSR) mode depending on measuring point duration and sampling rate.

[3] Theoretical value (duration per cycle = 2 years)

[4] Higher frequencies are possible using multi-wave functionality (942 rad/s (150 Hz) or even higher, depending on measuring system and sample)

[5] MCR 702e Space MultiDrive: Unique maximized workspace below the rheometer support plate and on both sides of the instrument

[6] Depending on used temperature device

[7] Customized systems used in CTD 1000