The E50 De-Contaminators from Evactron are high performance, compact yet streamlined plasma cleaners designed for ion and electron beam instruments, like FIBs, TEMs and SEMs.

The Evactron E50 Plasma Radical Source (PRS) has a compact design that makes it a multipurpose solution for load locks, SEM/FIB chambers, or sample preparation chambers. It provides rapid, effective, and robust cleaning across a broad range of pressures, allowing artifact-free, high quality pictures and improved efficiency of sample analysis.

There are two configurations in the Evactron E50 alternate gas PRS—the precision filter (0.5-μm pore size) model for general laboratory conditions and an ultra-high purity filter (3-nm pore size) model to fulfill the rigorous needs of the semiconductor sector SEMI F38-0699 directive.

The in-line filters avoid the entry of particulates, produced from gas feedlines, into the plasma stream. Alternative gases, which have been verified, include CDA, O2, Ar/O2, Ar/H2, N2, and H2/N2. For safety reasons, the use of 100% H2 is not suggested.

E50 Alternate Gas System Features

- Energy-efficient radiofrequency hollow cathode plasma (RFHC)

- Dual-action cleaning with UV and plasma afterglow

- RF power—75 W peak, up to 50 W continuous

- Wired touchpad programming or Bluetooth Android tablet

- Programmable power, recipes, number of cycles, and cleaning time

- High-vacuum 'pop' ignition

- Compatible with TMP and advanced venting is not required

- External interlock connection (optional)

- A broad range of pressure operation—0.3 Pa/2 mTorr to 80 Pa/600 mTorr

- Does not damage sensitive components—no sputter etch

- Gases for plasma include CDA, O2, Ar/O2, Ar/H2, N2, and H2/N2

- Enables rapid cleaning that is more than 100 times faster than the previous generation Evactron models

- PRS can be set up on the load lock or the SEM chamber

- Match or gas flow changes are not required for plasma ignition

- Push-button cleaning operation

- Complies with RoHS, NRTL, TUV, CE, and SEMI standards

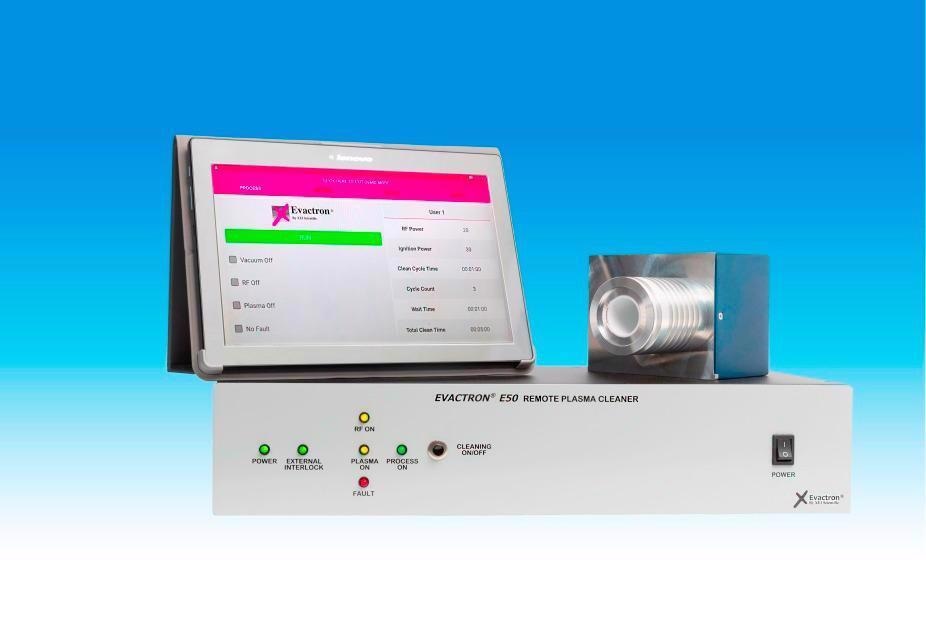

Image Credit: Evactron E50 (XEI Scientific)

Equipped with wireless tablet programming, the Evactron E50 Plasma De-Contaminator was developed to eliminate hydrocarbon contamination from high vacuum chambers, like FIBs and SEMs. The compact design of the Evactron E50 fits a majority of the FIB and SEM models and load-locks. The E50 uses air and alternate gas plasma with UV afterglow to quickly decrease hydrocarbon contamination.

Specifications of Evactron E50 Alternate Gas System

- Hardware interlock

- Desktop controller equipped with push-button operation

- Bluetooth communication package and Android tablet

- Offers 100–240 VAC 50/60 Hz input

- RF power—35 to 75 W at 13.56 MHz RFHC

- Chassis dimensions—width × height × depth: 17.2″ × 3.5″ × 8.6″ (44 × 8.9 × 22 cm)

- RoHS, NRTL, TUV, CE, and SEMI compliant

E50 E-TC Alternate Gas System

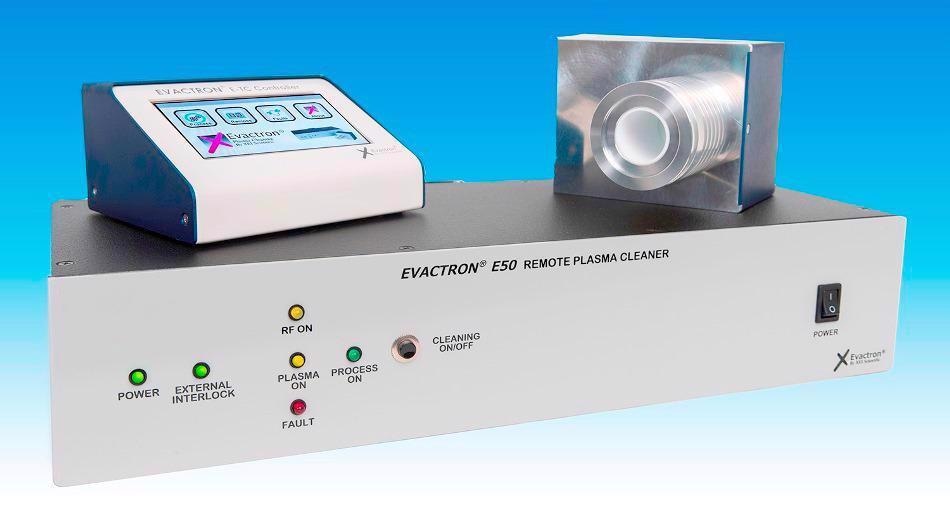

Image Credit: Evactron E50 E-TC (XEI Scientific)

The Evactron E50 E-TC Plasma De-Contaminator was specifically developed for facilities where a wired touchpad interface for programming is required. The touchpad (134 × 112 × 69 mm) is linked to the controller through an RS-232 cable. The Evactron E50 E-TC shares the features of the Evactron E50, using air and alternate gas plasma with UV afterglow to decrease hydrocarbon contamination and thus provides rapid results.

Specifications of Evactron E50 E-TC System

- The tethered touchpad communication package

- Desktop controller with push-button operation

- Hardware interlock

- Offers 100–240 VAC 50/60 Hz input

- RF power—35 to 75 W at 13.56 MHz RFHC

- Chassis dimensions—width × height × depth: 17.2″ × 3.5″ × 8.6″ (44 × 8.9 × 22 cm)

- RoHS, NRTL, TUV, CE, and SEMI compliant

- Plasma chemical etch plus UV active desorption

- External hollow cathode plasma radical source

- No sputter etch damage or debris

- Easy to use sample and chamber cleaning

- Plasma strikes at high vacuum, no venting required

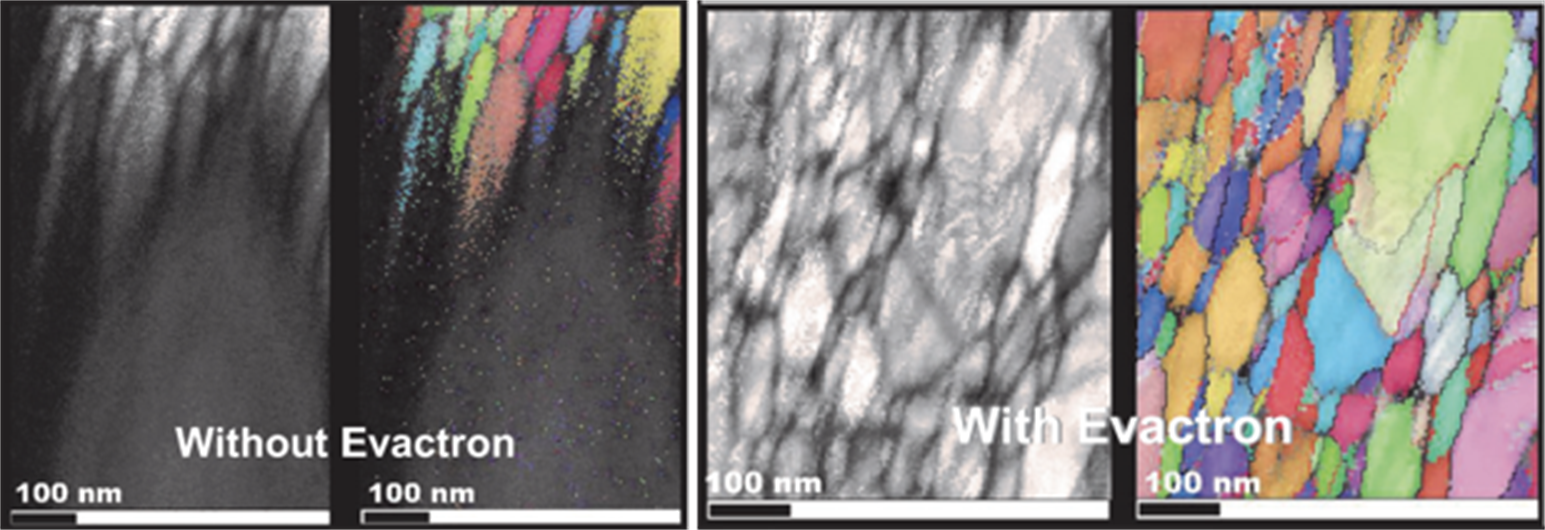

Image Credit: Evactron (XEI Scientific)

Image Credit: Evactron (XEI Scientific)

Plasma cleaning of the sample prior to TKD experiments affords many advantages. The improvement in pattern quality and enhanced measurement efficiency is needed for extended experiments, which can include fast and multiple scans at the same sample position (e.g., for repeated in-situ heating or straining experiments). The advantage of plasma cleaning is recommended for all high resolution TKD experiments. Plasma cleaning the sample inside the microscope chamber is recommended since the chamber, detectors and the holder are cleaned simultaneously.