The ContourX-200 Optical Profilometer from Bruker Life Sciences Mass Spectrometry offers the ideal blend of sophisticated characterization, tailorable options, and user-friendliness for top-rated quick, precise, and repeatable non-contact 3D surface metrology.

The gage-capable and compact footprint system provides no-compromise 2D or 3D high-resolution measurement abilities utilizing a bigger FOV 5 MP digital camera and a new motorized XY stage.

The ContourX-200 consists of boasting Z-axis resolution and precision and offers all the industry-recognized benefits of Bruker’s proprietary white light interferometry (WLI) technology without the restrictions of traditional confocal microscopes and rival standard optical profilers.

Automation Capabilities

Enables routines for quicker measurement and analysis.

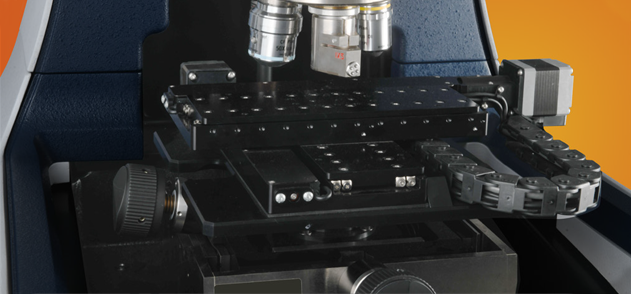

Motorized XY Stage

Offers low-noise and high-speed operation for quantitative metrology.

Vibration-Tolerant Compact Design

Provides measurement stability and gage-capable repeatability.

Features

Uncompromised, Best-in-Class Metrology

Built upon more than 40 years of proprietary WLI innovation, the ContourX-200 optical profilometer offers low noise, high-speed, precision, and precision outcomes that are needed by quantitative metrology.

Using multiple objectives and combined feature recognition, it is possible to monitor the features over a range of fields of observation and at the sub-nanometer vertical resolution, thereby offering scale-independent outcomes for quality control and process-monitoring applications in highly diverse industries.

ContourX-200 is strong in all surface situations ranging from 0.05% to 100% reflectivity. New hardware features consist of an innovative stage design for bigger stitching abilities and a 5 MP camera with a 1200x1000 measurement array for larger field-of-view, lower noise, and greater lateral resolution.

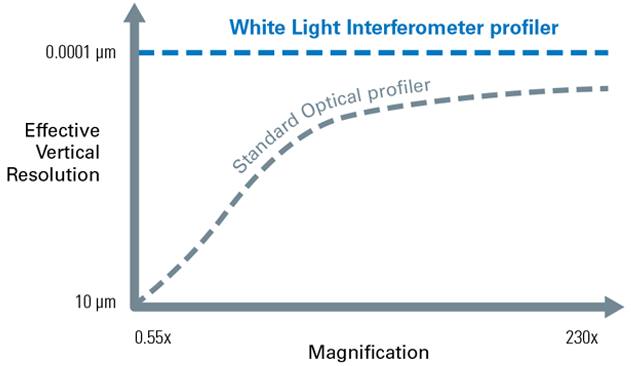

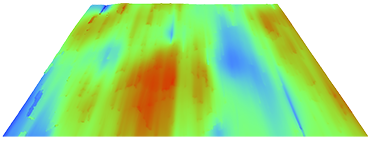

WLI offers constant and ultimate vertical resolution for all objectives. Image Credit: Bruker Life Sciences Mass Spectrometry

Widest Application Analysis Capabilities

With the help of efficient VisionXpress and Vision64 user interfaces, the ContourX-200 provides thousands of tailored analyses for productivity in laboratories and on factory floors.

New Universal Scanning Interferometry (USI) measurement mode from Bruker offers the self-sensing surface texture, and completely automated, optimized signal processing while providing the most precise and realistic computation of the surface topography that is being examined. The bigger FOV offered by the new camera and flexibility of the system afforded by the new motorized XY stage allows more flexibility and greater throughput for a broad range of samples and parts.

The hardware and software integration offer simplified access to top optical performance, thereby entirely outclassing comparable metrology abilities.

ContourX-200 motorized stage. Image Credit: Bruker Life Sciences Mass Spectrometry

Applications

Surface-Independent Metrology with Application-Specific Solutions

Precision Engineering

Users can retain the surface texture and geometric dimensions of precision-engineered parts within tight specification limits. The gage-capable measurement systems offer effective feedback and reporting as users monitor, track, and calculate processes and assess GD&T conformance.

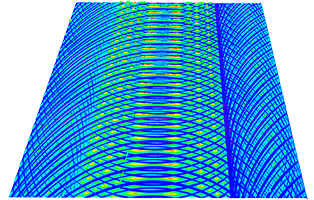

Image Credit: Bruker Life Sciences Mass Spectrometry

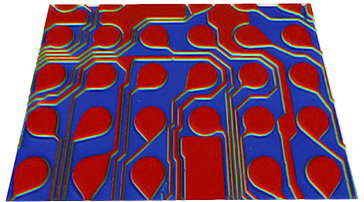

MEMS and Sensors

Users can execute high-throughput, film thickness, highly repeatable etch depth, step-height, and surface roughness measurements, as well as improved critical dimension metrology of optical MEMS and MEMS.

Optical profiling has the potential to define devices across the manufacturing process from wafer to final test, and even via transparent packaging.

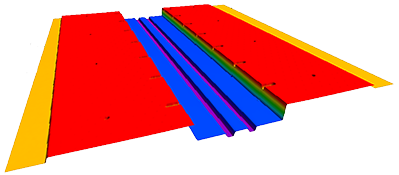

Image Credit: Bruker Life Sciences Mass Spectrometry

Orthopedics/Ophthalmics

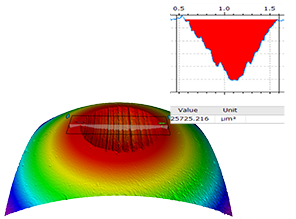

Users can achieve accurate, repeatable measurements of implant materials and components via the whole product life cycle. The WLI optical profilers support R&D, QA, and QC analyses, for applications varying from the characterization of surface parameters of lens and injection molds to surface finish verification and wear of medical devices.

Image Credit: Bruker Life Sciences Mass Spectrometry

Tribology

Examine, quantify, and manage the effect of friction, lubrication, wear, and corrosion on lifespans and material/component performance. Find quantitative wear parameters and execute fast pass/fail inspections on the extensive range of smooth, rough, or shiny surfaces.

Image Credit: Bruker Life Sciences Mass Spectrometry

Semiconductors

Enhance productivity and decrease costs for front- and back-end manufacturing processes using non-contact, automated, wafer-scale metrology systems. Execute post-CMP die flatness inspection; coplanarity, bump height, and flaw determination and examination; and quantify the critical dimensions of component structures.

Image Credit: Bruker Life Sciences Mass Spectrometry

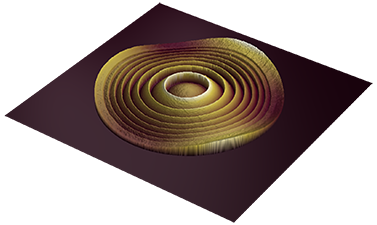

Optics

Better comprehend the underlying reasons for defects and improve polishing and finishing processes with precise and repeatable sub-nm roughness measurements. The non-contact metrology systems allow agreement with increasingly strict conditions and ISO norms for samples that range from tiny aspheric and free-form optics, to optical components that have complex geometries, to microlenses and diffraction gratings.

Image Credit: Bruker Life Sciences Mass Spectrometry