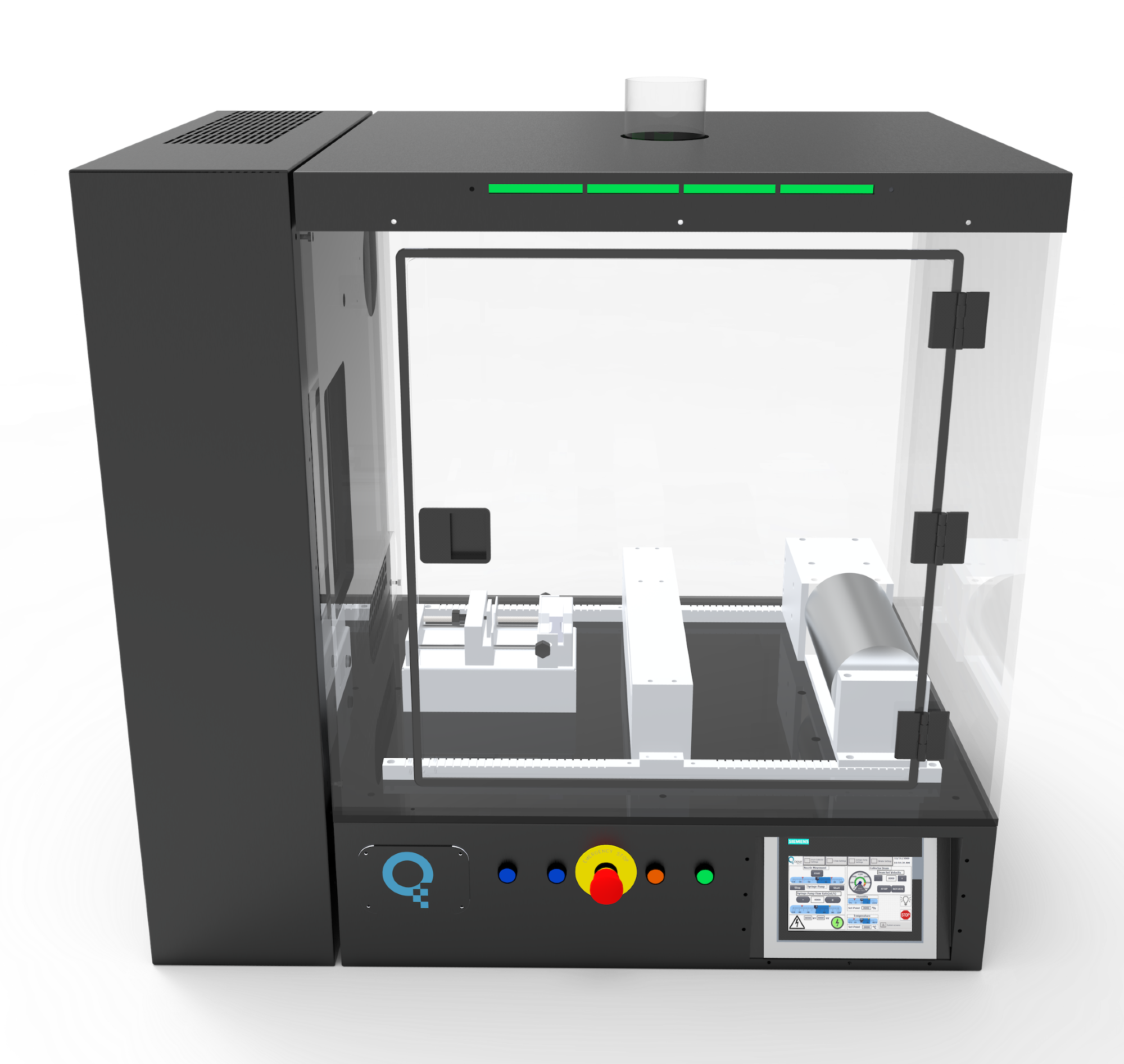

Spingenix SG100 is a fully automated electrospinning system for laboratory research applications.

Brief Explanation

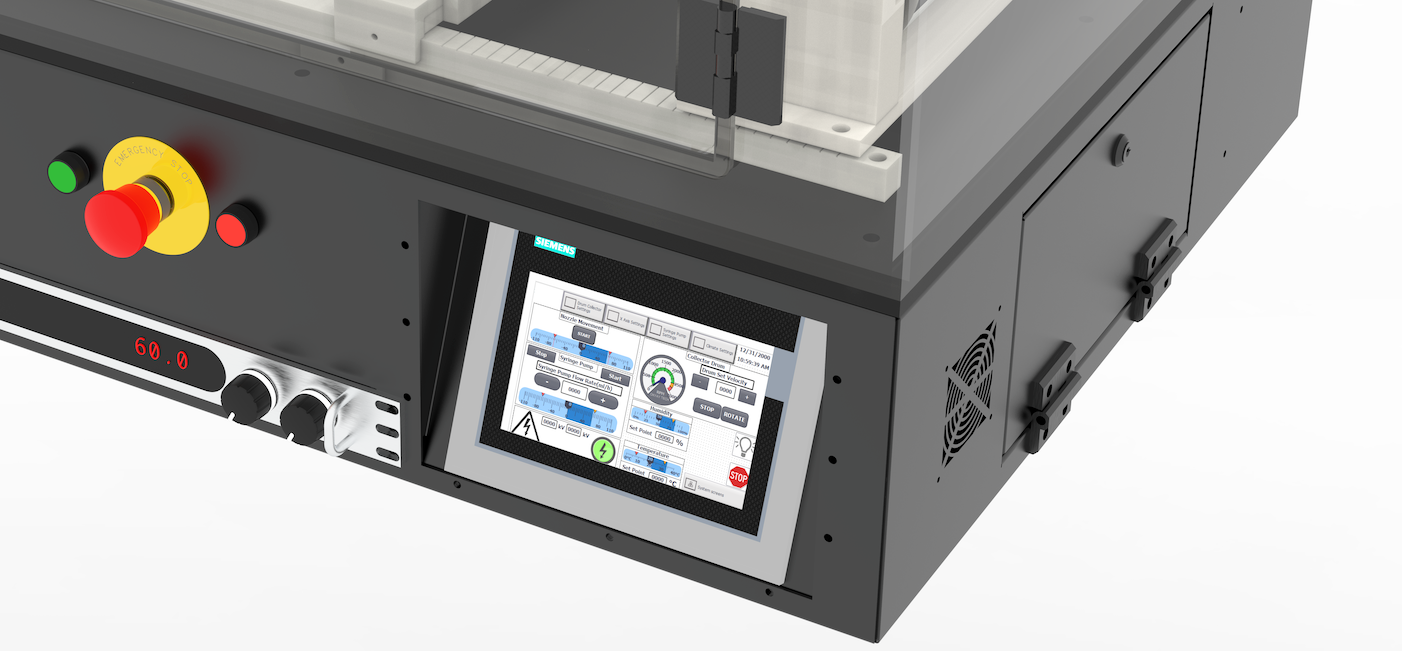

SG100 is a versatile research tool designed for university research laboratories. SG100 is a benchtop system with an efficient design to occupy minimum real estate in your laboratory. SG100 uses Matsusada 0-30kV continuously tunable power supply and it is equipped with a Siemens touch-panel display and Siemens PLC electronics for industry-level reliability.

The built-in software is user-friendly and it can be operated with minimal training. All process parameters can be controlled and monitored from the graphical user interface with an option to create and save recipes. There are also options for upgrades on this system at the time of system purchase or field upgrade after purchase.

Standard recipes to manufacture nanofibers are available from Spingenix as part of the vision for a strong commitment to the scientific and technical support of the users.

Image Credit: Spingenix

Unique Properties

- Flat collector for nanofiber deposition

- Easy to use practical control via touch screen panel

- High throughput production with special single nozzle

Optional Accessories

Different Diameter Needles

Electrospinning needles with the following diameters: (13G, 14G, 15G, 16G, 17G, 18G, 19G, 20G, 21G, 22G, 23G).

Coaxial Nozzle

- Extra syringe pump

- Custom sizes available (e.g., Inner Diameter: 0.8 mm, Outer Diameter: 1.6 mm)

- Specially designed coaxial nozzle to produce core-shell, hollow and bi-component nanofibers

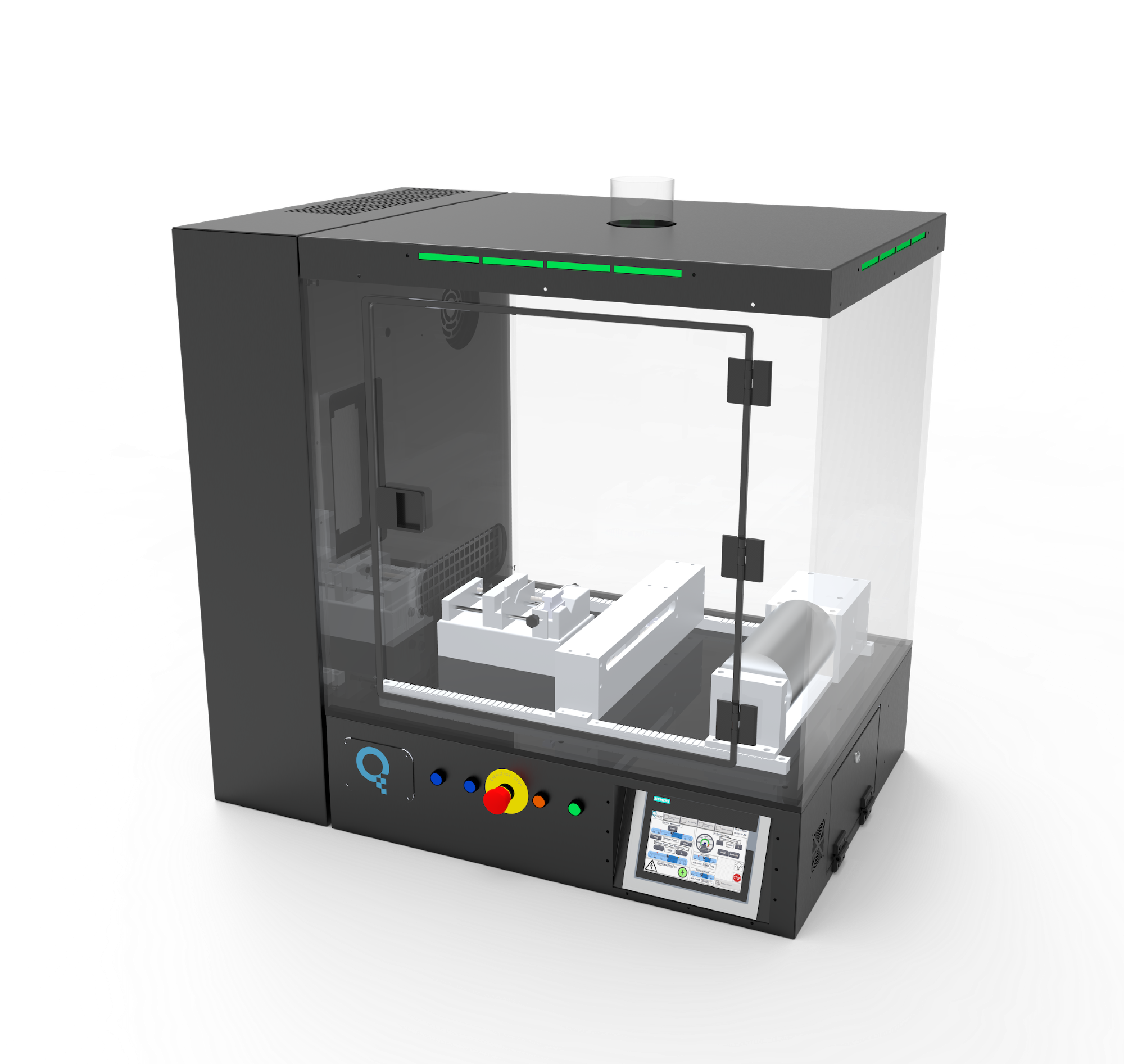

Shelf System

The shelf system organizes accessories and extra parts inside the cabin.

Image Credit: Spingenix

Climate Controlled Chamber

- Fully automated and GUI-integrated

- Cooling/Heating 15 °C–45 °C

- +/–1C Siemens PLC PID control

- Humidity control 20%–50% Rh

- +/– 2% Rh Siemens PLC PID control

Rotating Mandrel Collector

6 mm diameter rotating shaft collectors for tubular nanofiber membrane production.

Bio Sterilization

Deep ultraviolet light is used to sterilize the cabin to produce biocompatible nanofibers.

Fiber Curing

Fiber curing system while producing nanofibers.

Taylor Cone Imaging System

- Real-time close monitoring of the Taylor Cone to enable finding underlying mechanisms

- USB controlled camera, objective lens, and mounts

Extended Warranty

- Annual maintenance contract

- The warranty period for standard systems is one year. Furthermore, an extended warranty is an option to cover the machine.

Image Credit: Spingenix