The GranuPack Permeability Unit by Granutools represents a groundbreaking advancement in the field of powder permeability analysis.

The Significance of Understanding Powder Permeability

In powder processing, powder permeability is a crucial factor across various sectors, including pharmaceuticals, food production, and additive manufacturing. Thus, a proper understanding of powder behavior under different packing conditions is essential for enhancing product quality and production efficiency in these sectors.

This is where the GranuPack Permeability Unit can be highly advantageous. This innovative piece of equipment is set to change how powder permeability is quantified and applied.

Exploring the GranuPack Permeability Unit: A Game-Changer in Powder Permeability Measurement

Image Credit: Granutools

The GranuPack Permeability Unit is a cutting-edge instrument specifically designed to test powder permeability under various packing conditions. Setting it apart from other systems on the market, this unit can provide extensive insight into how powders react when subjected to varied amounts of consolidation and density.

Outlined below are some of the stand out components and characteristics of the GranuPack Permeability Unit:

- Permeability Measurement Cell: The permeability measurement cell is fundamental to the GranuPack Permeability Unit. The bottom of this cell has a porous frit that lets air flow through the powder sample. Precise and regulated measurements of permeability are guaranteed by this design.

- Mass Flow Controller: One feature of the unit is a mass flow controller, which controls the airflow rate within the cell. Exact control of the airflow is necessary to ensure consistent and precise readings.

- Unique Measurement Technique: The GranuPack Permeability Unit employs a distinctive measurement technique. By alternating the application of taps to the powder with air insufflation through the powder bed, it is possible to measure the powder permeability at various packing fractions. This enables a comprehensive understanding of how powders behave under different conditions.

Unveiling the Key Features of the GranuPack Permeability

Image Credit: Granutools

The GranuPack Permeability Unit boasts several key features that set it apart:

- Simultaneous Measurement of Permeability and Density: One of its standout features is the simultaneous measurement of both permeability and density. This dual-capability approach offers a comprehensive understanding of powder behavior, leading to enhanced process optimization.

- Measurement of Permeability at Low Consolidation: The unit is highly effective in measuring permeability, even at low consolidation levels, which is vital in industries like pharmaceuticals and food production, where maintaining powder flowability is key.

- Measurement of Permeability in Static Conditions: Distinct from methods that necessitate fluidization, the GranuPack Permeability Unit can measure permeability in static conditions. This unique capability broadens its range of applications, enhancing both its versatility and reliability.

The GranuPack Permeability Unit stands out for its capacity to measure powder permeability under various packing conditions. This distinctive feature enables researchers and manufacturers to fine-tune their processes, guaranteeing consistent product quality.

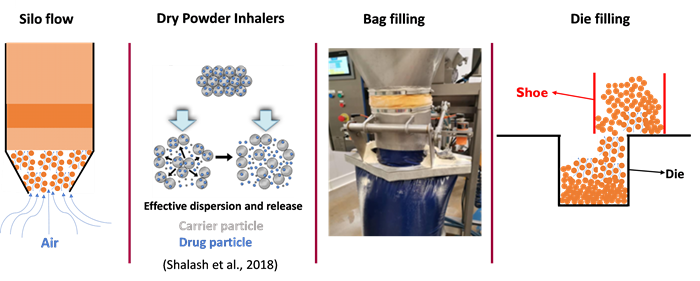

Versatile Applications of the GranuPack Permeability Unit Across Industries

Image Credit: Granutools

The GranuPack Permeability Unit is used in a variety of sectors, including:

- Bag Filling: Efficient bag filling requires knowledge of powder permeability to prevent clogs and ensure uniform filling.

- Dry Powder Inhalers (DPI): The pharmaceutical industry benefits from precise measurements of powder permeability in DPIs, ensuring accurate drug delivery to patients.

- Die Filling: In manufacturing, die filling is crucial for producing consistent and high-quality products. The GranuPack Permeability Unit helps to optimize this process.

- Vertical Flow Inside a Silo: Understanding how powders behave in silos is essential for optimizing storage and flow in industries like agriculture and mining.

A Bright Future for Powder Characterization

To sum up, GranuPack Permeability represents a major development in the field of measurement and processing powders. With its comprehensive insights on powder behavior under different packing conditions—such as low consolidation and static scenarios—it empowers industries to improve product quality, streamline processes, and maintain a competitive edge.

One of the key factors influencing a powder’s processability (flowability, compressibility, packing ability, etc.) is its permeability, which makes quantifying it crucial. This emphasizes how important accurate measurement is, which makes GranuPack Permeability a vital tool for companies looking to streamline their processes.

Never underestimate the importance of this innovative particle permeability analysis tool.