Since the advent of the first rechargeable battery, portable power has evolved into an indispensable aspect of modern life. Lithium-ion batteries (LIBs) have revolutionized energy storage and usage, catering to a diverse array of applications ranging from cell phones to electric vehicles.

With the highest energy density out of all the types of batteries available, LIBs have a strong potential for improving performance and reducing environmental impact.

Bruker solutions help researchers advance battery technology discoveries and foster a sustainable future.

Next-Generation Batteries

Scientists are now focusing their attention on the next generation of batteries in an effort to develop more environmentally friendly energy sources. Research and development on alternative battery technologies, like solid-state and sodium-ion batteries, is still ongoing and may have advantages in the form of lower costs, higher sustainability, and increased safety.

Sodium-ion batteries, for example, are a more environmentally friendly choice for large-scale energy storage because sodium-ion batteries are constructed from readily available and inexpensive materials. Conversely, solid-state batteries are safer and have a higher energy density, which makes them perfect for use in electric vehicles.

Bruker offers cutting-edge solutions that support a sustainable future for all by enabling academic researchers and battery manufacturers to investigate and innovate in the field of battery technology.

Lithium-Ion Batteries

LIBs have a high energy density, so they are a better option than other battery types because LIBs can improve performance and lessen their environmental impact.

Image Credit: Bruker BioSpin - NMR, EPR and Imaging

Solid-State Batteries

Solid-state batteries are gaining traction as a viable LIB substitute due to their enhanced safety features and higher energy density.

Image Credit: Bruker BioSpin - NMR, EPR and Imaging

Sodium-Ion Batteries

With their low-cost and abundant materials, sodium-ion batteries are gaining traction as a sustainable option for large-scale energy storage.

Image Credit: Bruker BioSpin - NMR, EPR and Imaging

Powering a Greener Future with Magnetic Resonance

Creating a sustainable and greener world is crucial to ensure the future of our planet. To achieve this, advanced, recyclable batteries with higher energy density, longer cycle life, and lower cost are needed. This will enable the uptake of renewable energy, reduce reliance on fossil fuels, and help to mitigate climate change.

New technologies like grid-scale energy storage systems and long-range electric vehicles will be made possible by advancements in battery technology. Researchers are looking into new battery chemistries and materials, as well as new production and recycling techniques, to accomplish this.

Nuclear magnetic resonance (NMR) and electron paramagnetic resonance (EPR) are set to play a massive part in this by offering researchers important new insights into the characteristics of battery materials and contributing to the advancement of battery technology.

Exploring Battery Materials with Advanced Analytical Techniques

Researchers and manufacturers can examine battery materials at the molecular and atomic levels, thanks to the potent instruments of NMR and EPR. These methods offer important insights into the electrochemical processes, the physical and chemical alterations in the electrode and electrolyte materials, and the variables influencing the effectiveness and performance of batteries.

Researchers and manufacturers can create strategies to enhance battery longevity and performance by comprehending the behavior of these materials, which will ultimately result in more sophisticated, economical, and environmentally friendly batteries. By enhancing energy storage, these cutting-edge analytical methods contribute significantly to battery innovation and the fight against climate change.

NMR: A Powerful Tool for Optimizing Battery Performance

In chemistry and materials science, nuclear magnetic resonance (NMR) is a commonly used analytical technique that offers researchers a deeper understanding of the behavior and properties of battery materials. NMR analysis of battery materials’ atomic and molecular structures helps researchers understand the chemical and physical alterations that take place during charge and discharge cycles.

To measure these processes and critical quality attributes effectively, analytical solutions for the characterization of batteries should be able to operate in situ.

NMR spectroscopy offers an ideal analytical method to address the need for accurate, responsive, in situ detection in the battery sector. It assists in identifying reasons for battery degradation and failure, enabling the development of new, more durable, and stable electrode materials.

By providing a detailed analysis of the chemical and physical properties of battery materials, NMR helps optimize battery performance and efficiency.

Image Credit: Bruker BioSpin - NMR, EPR and Imaging

Specialized Solid-State NMR Probes and In-Situ NMR Accessories for Battery Research

Specialized solid-state NMR probes and in situ NMR accessories created in collaboration with ePROBE, a pioneer in battery analysis technology solutions, are among the many tools available from Bruker for battery research.

These probes have current collector ports for charging and discharging electrochemical cells inside the NMR magnet. NMR probes come in single or double-resonance configurations.

The probes also have integrated gas or liquid flow channels, which enable researchers to study systems like metal-air batteries and redox-flow.

The in situ solid-state NMR equipment from Bruker offers a potent tool for battery performance optimization. Analytical solutions for battery characterization that function in situ are able to measure processes that take place during charge and discharge cycles and precisely identify important quality attributes.

With the help of ePROBE’s technologies and Bruker’s state-of-the-art RF generation console, AVANCE NEO, researchers can obtain valuable insights and reap the benefits of optimized R&D and quick and precise quality inspection tasks.

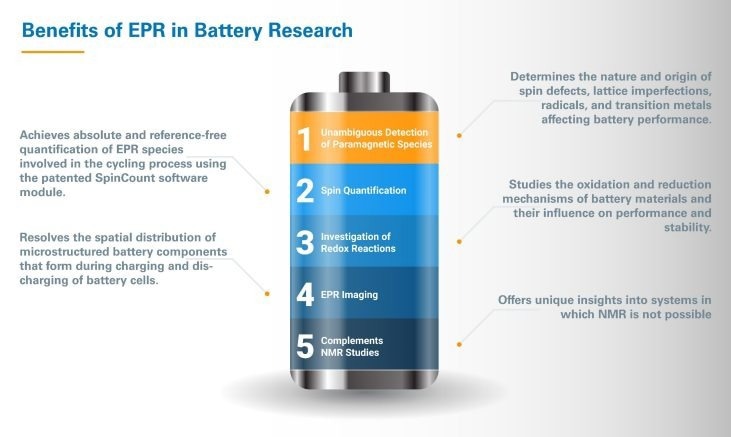

EPR: Advanced Technique for Improving Battery Stability and Efficiency

Electron Paramagnetic Resonance (EPR) is an advanced spectroscopic technique that detects unpaired electrons in materials. EPR offers insights into material behavior under electrochemical conditions by identifying free radicals responsible for electrode material degradation during charge and discharge cycles.

To create more effective electrode materials for energy storage and raise the stability and efficiency of batteries, researchers use electron photovoltaics to study electron transfer processes and determine the factors influencing their rate and efficiency.

Advanced in-situ EPR imaging (EPRI), which offers insights into dendritic microstructural properties, growth mechanisms, and plating/stripping processes for safer and more effective batteries, is part of Bruker’s battery research portfolio. Researchers and manufacturers can improve battery performance and stability by using EPR to understand battery materials better.

Image Credit: Bruker BioSpin - NMR, EPR and Imaging

Optimize Battery Development and Manufacturing with MR

To remain competitive in the market, battery manufacturers are continuously seeking ways to refine their manufacturing workflows, boost production rates, enhance operational speed and efficiency, and maximize the use of resources. In-depth investigations are fundamental to addressing these challenges, and techniques such as solid-state in situ NMR spectroscopy provide a dependable, comprehensive analytical tool. This technique is crucial in maintaining the consistent quality of battery components and materials, such as electrodes, electrolytes, and separators, throughout the entire value and supply chain of battery manufacturing.

Magnetic resonance technology can also monitor battery production processes, identifying any defects or inconsistencies that may compromise battery performance or safety. By leveraging magnetic resonance technology, battery manufacturers can enhance their production capabilities, streamline the value chain, and develop more efficient, durable, and cost-effective battery solutions that meet the growing demands of the market.