Siemens aims to enhance the solar thermal plant’s efficiency and in turn reduce power generation costs. Hence, the company’s researchers intend to use molten salts, a blend of potassium and sodium nitrates, in solar thermal projects.

Researchers from Siemens intend to substantially boost the efficiency of solar thermal power plants and thus reduce the costs of this climate-neutral method of power generation.

Researchers from Siemens intend to substantially boost the efficiency of solar thermal power plants and thus reduce the costs of this climate-neutral method of power generation.

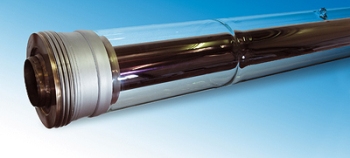

To achieve this aim, Siemens plans to build a pilot facility in Portugal for testing application of molten salts as a heat transfer medium in parabolic power plants. The parabolic power plants employ concave parabolic mirrors, which focuses sunlight using an absorber tube. The tube allows the heat transfer medium to flow through it. Later, the heat gets transformed into power by a generator and a steam turbine. Heat transfer medium’s highest working temperature determines the thermal power process efficiency.

University of Evora in Portugal has been chosen for construction of the pilot facility. The plant will be equipped with a steam generator, pipework system, solar components and pumps to manage the temperatures and properties of heat transfer media and molten salts. Siemens’ scientists will use the pilot results for implementation at commercial plants with more than 50 MW of installed powers. Federal Ministry for the Environment, Germany is funding this solar thermal pilot plant project.

Siemens Corporate Technology and Siemens Energy researchers work on a major goal to enhance properties and composition of molten salts. Molten salts will be used as an alternative for thermal oil. This boosts the working temperatures ranging from 400° to over 500° Celsius. High vapor pressure and extremely flammable property are major drawbacks of thermal oil, whereas molten salts have about zero vapor pressure and they are non-flammable. Hence, power plant operations will be safe without pressure. In addition, molten salt mixtures possess greater heat storage ability and they are economical for use.