Oct 26 2011

Taha International, a Bahrain based company expanded its dross recycling operations throughout the world after recently opening a multimillion-dollar factory at Tiwai Point, Bluff in New Zealand.

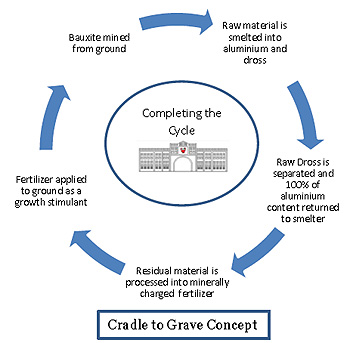

The Dross Recycling Facility was officially opened in October with a formal ceremony and Maori blessing. This Bahrain-based company has developed an environmentally sensitive, efficient, and cost-effective process to separate aluminium from dross, and produce fertilizer from the aluminium oxide residue. The company uses a mechanical separation process, which has found favour in New Zealand and is poised for introduction in other places.

Taha Asia Pacific established a Hot Dross Processing System whereby the majority of metal is recovered without the need for additional energy or additives. The depleted dross is meticulously separated by mechanical means; a process which extracts fine metal particles. What remains is a high grade mineral, known as aluminium oxide.

The extracted metal is then processed even further in a specialised furnace to ensure that the client receives the highest possible return. Taha then converts the aluminium oxide in to various products but it is mainly used in the manufacture of mineral fertilizer that already has international approvals and certification in Germany and the European Union.

Taha Asia Pacific Ltd (the New Zealand subsidiary of Taha International Corporation) currently employs 22 people, and they recycle aluminium dross using a mechanical system to extract every last trace of aluminium metal which is returned to smelter. In August 2011, they began processing dross that the smelter produces annually as well as treating dross that is stored in the landfill (within Tiwai). What remains is high-grade aluminium oxide, which is further processed by another company, Taha Fertilizer Industries, who convert it into mineral fertilizer.

Taha Asia Pacific recently formed a partnership with Invest South Limited Partnership in order to strengthen their ever-expanding operations in the Asia and Pacific region. When Rio Tinto tendered worldwide for dross processing, Taha Asia Pacific put up its hand to take on the job. The Rio Tinto/NZAS plant is one of the most efficient and environmentally conscious of its type in the world, which is why they wanted to set up their first plant there. Transparency is important as the plant operates from within Rio Tinto's Aluminium Smelter, at Tiwai Point.

Taha Fertilizer Industries is scheduled to begin operations in November 2011, and will employ a further 10 people. Staff will regularly test and analyse fertilizer blends, and will create custom product to suit individual crops and locations. Locally manufactured fertilizer is more than just recycling; it also ticks the environmental boxes in terms of miles to market.