Apr 2 2015

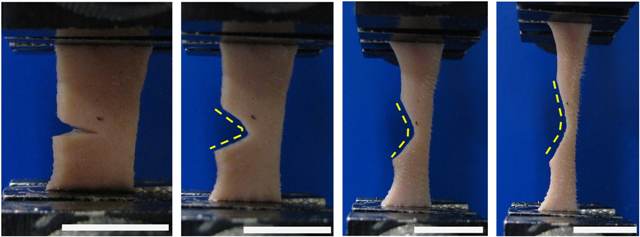

Sequence of images showing how skin when torn does not propagate but progressively yawns open under tensile loading.

Sequence of images showing how skin when torn does not propagate but progressively yawns open under tensile loading.

The team of researchers utilized the Berkeley Lab’s Advanced Light Source (ALS) for the study. X-ray beams were used to observe micro-scale mechanisms that enables skin to be resistant to tearing. The skin tissue’s main structural protein is collagen. This was found to have four specific mechanisms that acted synergistically for reducing the effects of stress.

Collagen fibrils and fibers rotate, straighten, stretch and slide to carry load and reduce the stresses at the tip of any tear in the skin. The movement of the collagen acts to effectively diminish stress concentrations associated with any hole, notch or tear.

Robert Ritchie - Co-leader of the Study

Berkeley Lab's Material Sciences Division

Most people monitor the condition of their skin, with its appearance being of primary importance. The skin serves many important purposes including collection of thermal energy, regulation of temperature, environmental protection, and it acts as a host for sensors.

The skin is made up of three layers; the epidermis, endodermis and dermis. The dermis is the thickest layer and it determines the mechanical properties of skin. Collagen and elastin proteins make up this dermis layer. The mechanical resistance to extension is provided by the collagen. Deformation that takes place in response to low strains is allowed by elastin.

In 1831, a patient with stab wounds visited a physician, and claimed that they were self-inflicted. This led to studies of the mechanical properties of the skin. Based on these studies, scientists characterized skin as a material that had low strain-rate sensitivity and is nonlinear-elastic. Most studies in recent years have been conducted on collagen deformation. Very few studies have been done on tearing of the skin, even though skin demonstrates superior tear-resistance when compared to other natural materials.

“Our study is the first to model and directly observe in real time the micro-scale behavior of the collagen fibrils associated with the skin’s remarkable tear resistance,” Ritchie said.

In situ tension-loading was performed on the dermis, and during this period, structural and mechanical characterizations were done. Ritchie, Marc Meyers (co-leader of the study, UC San Diego) and the other members of their research team performed these characterizations at the ALS beamline 7.3.3. Using small-angle X-ray scattering (SAXS) and ultra high-resolution scanning and transmission electron microscopy the research team obtained images for performing the characterizations.

“The method of SAXS that can be done at ALS beamline 7.3.3 is ideal for identifying strains in the collagen fibrils and watching how they move,” Ritchie said.

The researchers established that when a tear happens to the skin it does not cause a fracture. However, tooth dentin or bone that is made up of mineralized collagen fibrils can be damaged. The research team showed that notching or tearing skin causes structural changes to the dermis layer’s collagen fibrils that led to reduction in stress concentration.

The collagen fibrils became highly disordered and curvy, initially, and when a tear took place, these fibrils rearranged themselves in the direction of the tensile-loading. Before fracturing, they rotated, straightened, stretched, slided and delaminated.

The rotation mechanisms recruit collagen fibrils into alignment with the tension axis at which they are maximally strong or can accommodate shape change. Straightening and stretching allow the uptake of strain without much stress increase, and sliding allows more energy dissipation during inelastic deformation. This reorganization of the fibrils is responsible for blunting the stress at the tips of tears and notches.

Marc Meyers - Co-leader of the Study

UC San Diego

Ritchie and Meyers have been conducting studies on the way in which nature obtains specific properties through structure and architecture. The current study on skin forms part of this study.

“Natural inspiration is a powerful motivation to develop new synthetic materials with unique properties,” Ritchie says. “For example, the mechanistic understanding we’ve identified in skin could be applied to the improvement of artificial skin, or to the development of thin film polymers for applications such as flexible electronics.”

The other authors of this study are Wen Yang, Bernd Gludovatz, Polite Stewart, Eric Schaible and Vincent Sherman. This study has been published as a paper titled “On the tear resistance of skin” in the journal, Nature Communications.

The Air Force Office of Scientific Research provided the primary support for this study.