Oct 24 2016

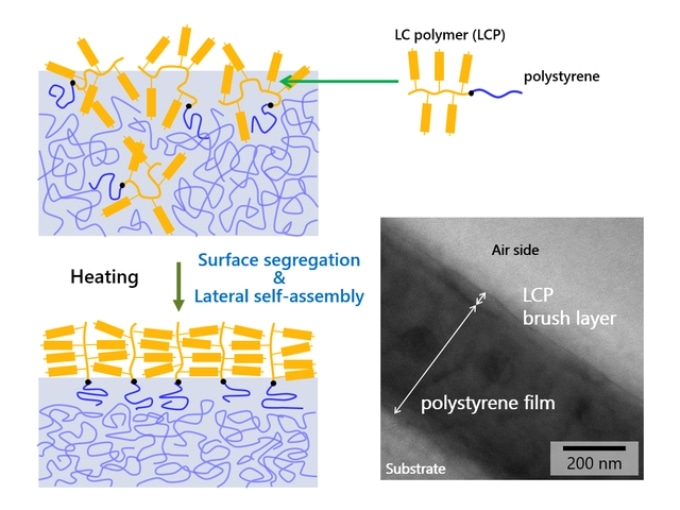

Schematic depiction of polymer brush formation through the surface segregation and lateral self-assembly of a block copolymer consisting of a liquid crystalline polymer (LCP) connected with polystyrene on a polystyrene base film. The photo displays a transmission electron microscopic (TEM) image showing the extended polymer brush layer formed on the air side of a polystyrene film. CREDIT: Nagoya University

Schematic depiction of polymer brush formation through the surface segregation and lateral self-assembly of a block copolymer consisting of a liquid crystalline polymer (LCP) connected with polystyrene on a polystyrene base film. The photo displays a transmission electron microscopic (TEM) image showing the extended polymer brush layer formed on the air side of a polystyrene film. CREDIT: Nagoya University

A group of researchers from Nagoya University have recently developed an approach to obtain polymer brushes on surfaces using diblock copolymers comprising of two kinds of units forming segregated structures.

Polymer surface coatings are vital for manufacturing surfaces that have optimum properties such as low friction, wettability, and biocompatibility. In general, surfaces are reformed using polymers with grafting techniques for forming chemical bonds between the polymer and the surface.

The kind of grafting technique can impact the ordering, having an affect on the characteristics of the polymer coating. For instance, polymer brushes are vertically tethered with reference to the underlying surface, and can exhibit properties that are entirely different from that of an identical polymer that has random orientation. Usually, polymer brushes are produced by initiating polymerization at surfaces.

The formation of polymer brushes was driven by the ability of our copolymers to segregate and self-assemble on a base polymer surface when heated appropriately.

Shusaku Nagano, Nagoya University

Initially, the team synthesized diblock copolymers consisting of poly(azobenzene) (PAz) and polystyrene (PS)-based units with differing properties such as flexibility and surface energy. Such difference in properties resulted in segregation of the copolymers into their disparate blocks on the PS substrate surfaces upon being annealed at a temperature greater than the glass transition temperature of PS.

The segregation was validated with transmission electron microscopy, contact angle measurements, and x-ray photoelectron spectroscopy. It was established that a “skin” was formed by the PAz units on the PS surface. The ratio between the two kinds of polymer units present in the copolymer determined the PAz skin layer’s thickness.

The main chain of PAz in the skin layer was greatly extended to form the brush structure. This phenomenon was due to the occurrence of the bulky azobenzene units in PAz.

Upon making ultraviolet-visible absorption measurements, it was found that a PS substrate blocked the diblock copolymer from being aggregated during the annealing process. The main chains of PAz were found to be in horizontal orientation solely in a film of the copolymer.

On the other hand, an underlying PS surface induced the main chains of PAz to be vertically oriented with reference to the surface. The reason is that the PS units in the diblock copolymer contact the underlying PS layer, forming a surface layer with PAz units that are vertically oriented and arranged like densely packed polymer brushes.

The generation of such a structure was caused mainly due to the lower surface tension of the PAz units when compared to the PS units, as well as due to the PAz units’ potential to get self-assembled.

The benefits of this technique include the potential to obtain polymer brushes on flexible substrates as well as the effortless controllability of brush structure and thickness by modifying the kind and/or number of units present in the diblock copolymer.

These organized polymer surfaces are stable in air and should be resistant to damage.” He further stated that “A damaged surface should be able to self-heal simply by annealing because of the lateral mobility of the polystyrene anchoring units.

Koji Mukai, Nagoya University

The photosensitive azobenzene units present in the PAz brushes can be further aligned by exposing them to light irradiation. This procedure can possibly be extended to form functional surface coatings by carrying out segregation cum self-assembly of the diblock copolymers with other polymer systems.

The article, "High-Density Liquid-Crystalline Polymer Brushes Formed by Surface Segregation and Self-Assembly" was featured in Angewandte Chemie International Edition.

The work received financial aid from Japan Society for the Promotion of Science.