Oct 31 2016

hxdbzxy/Shutterstock.com

hxdbzxy/Shutterstock.com

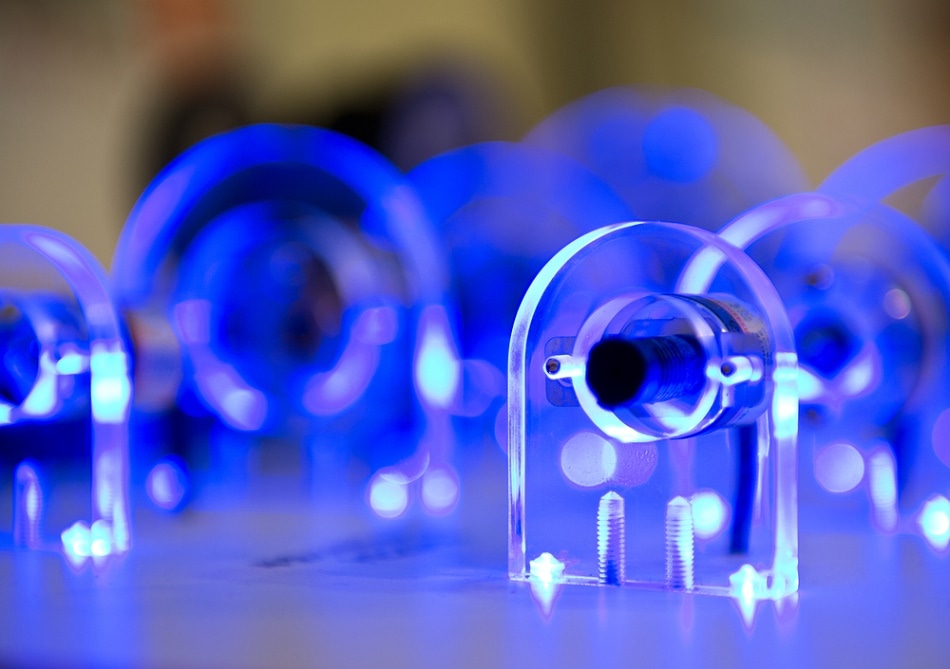

Gallium nitride (GaN) has become one of the most significant and extensively used semiconducting materials. Due to its mechanical and optoelectronic properties it is highly suited for various applications such as high-temperature transistors, light-emitting diodes (LEDs), biocompatible electronic implants in humans and sensors.

In 2014, three Japanese researchers were awarded the Nobel Prize in physics for their discovery of GaN’s important role in generating blue LED light, which must be combined with green and red lights to generate white LED light sources.

Recently, a previously unknown property of GaN has been reported by a team of four Lehigh engineers - GaN’s wear resistance approaches that of diamonds. This can open new applications in space vehicles, radio-frequency microelectromechanical systems (RF MEMS) and touch screens that need high-vibration technology and high-speed.

This new finding was reported in Applied Physics Letters (APL) under an article titled "Ultralow wear of gallium nitride," in August, 2016. Guosong Zeng, a Ph.D. candidate in mechanical engineering; Nelson Tansu, Daniel E. '39 and Patricia M. Smith Endowed Chair Professor in the Electrical and Computer Engineering department, and Director of the Center for Photonics and Nanoelectronics (CPN); Brandon A. Krick, assistant professor of mechanical engineering and mechanics; and Chee-Keong Tan '16 Ph.D., now assistant professor of electrical and computer engineering at Clarkson University are the authors of the article.

Lead author of the article, Zeng said that GaN’s optical and electronic properties have been extensively explored for many decades, but no one has studied its tribological properties - the semiconductor’s resistance to the mechanical wear caused by reciprocated sliding.

Our group is the first to investigate the wear performance of GaN. We have found that its wear rate approaches that of diamonds, the hardest material known.

Guosong Zeng, Ph.D. Candidate, Lehigh University

Wear rate is expressed in the form of negative cubic millimeters of Newton meters (Nm). The wear resistance of chalk, which is virtually non-existent, is on the order of 10 2 mm3/Nm. Diamond’s wear resistance, however, ranges between 10-9 and 10-10. This means that chalks are eight orders of wear resistance less than that of diamonds. The wear resistance of GaN ranges from 10-7 to 10-9, approaching diamonds, and has three to five orders of magnitude higher than that of silicon (10-4).

The friction coefficients and wear rate of GaN was evaluated by the team, who used a custom microtribometer for performing dry sliding wear experiments. The results surprised them.

"When performing wear measurements of unknown materials," they wrote in APL, "we typically slide for 1,000 cycles, then measure the wear scars; [these] experiments had to be increased to 30,000 reciprocating cycles to be measurable with our optical profilometer.

"The large range in wear rates (about two orders of magnitude)...can provide insight into the wear mechanisms of GaN."

The engineers stated that numerous factors such as crystallographic direction environment, and humidity, in particular are the cause of the range in wear resistance.

The first time we observed the ultralow wear rate of GaN was in winter. These results could not be replicated in summer, when the material's wear rate increased by two orders of magnitude.

Guosong Zeng, Ph.D. Candidate, Lehigh University

In order to discover how GaN’s wear resistance is influenced by the higher summer humidity, the team placed the tribometer in a glove box, which can be backfilled with humid air or nitrogen.

"We observed that as we increased the humidity inside the glove box, we also increased the wear rate of GaN," said Zeng.

In October, 2016 Zeng spoke on this project at the International Workshop on Nitride Semiconductors (IWN 2016) that was held in Orlando, Florida. This presentation was a part of the session titled ‘Wear of Nitride Materials and Properties of GaN-based structures.’ Among the seven presenters who spoke at this session, Zeng was the only one to talk about the wear properties of GaN and that of other III-Nitride materials.

Tansu has been studying GaN for over 10 years, and Krick, who is a tribology expert, became interested in the wear performance of GaN many years ago during a discussion about their projects after a faculty meeting.

"Nelson asked me if anyone had ever investigated the friction and wear properties of gallium nitride," said Krick, "and I said I didn't know. We checked later and found a wide-open field."

Tansu stated that the finding of GaN’s wear performance and hardness can significantly affect the digital devices and electronics industries. He said that smartphones use protective coating of sapphire or glass to protect the electronic components. This can cause compatibility issues that can be prevented with the use of GaN.

The wear resistance of GaN, gives us the opportunity to replace the multiple layers in a typical semiconductor device with one layer made of a material that has excellent optical and electrical properties and is wear-resistant as well. Using GaN, you can build an entire device in a platform without multiple layers of technologies. You can integrate electronics, light sensors and light emitters and still have a mechanically robust device. This will open up a new paradigm for designing devices. And because GaN can be made very thin and still strong, it will accelerate the move to flexible electronics.

Nelson Tansu, Lehigh University

Zeng stated that GaN not only has good wear performance, but it also has good radiation hardness, which is a key property of the solar cells that are used for powering space vehicles. These solar cells come across extremely fine cosmic dust, gamma rays and x-rays in outer space, so they need a wear-resistant coating that must be compatible with the electronic circuitry of the cell. The required hardness can be provided by GaN, which will not cause any compatibility problems with the circuitry.

In order to better understand the interaction of water and GaN under contact, the Lehigh team has started to collaborate with surface chemistry expert, Bruce E. Koel, who is professor of chemical and biological engineering at Princeton University. Koel was earlier a chemistry professor and the vice president for research and graduate studies at Lehigh.

In order to find the evolution of wear with GaN, the researchers subjected GaN to stresses. They run slide tests with varying slide distance and the corresponding number of cycles. An x-ray photoelectron spectrometer (XPS), capable of identifying the elemental composition of the first 12 nanometers of a surface, was used for scanning the scar made by the slide machine, the resultant wear particles dumped by the slide machine and the unworn surface of the GaN.

In order to examine the lattice of atoms under the scar, the researchers intend to employ aberration-corrected transmission electron microscopy. To find out the variations caused by deforming energy, they will also stimulate a test where the lattice is strained with water.

This is a very new experiment. It will enable us to see dynamic surface chemistry by watching the chemical reaction that results when you apply shear, tensile or compressive pressure to the surface of GaN.

Guosong Zeng, Ph.D. Candidate, Lehigh University