Jul 18 2017

Supercapacitors are devices that have been aptly named as they are capable of storing and delivering energy in a much faster manner than standard batteries. They are in great demand for applications including high-powered lasers, wireless telecommunications and electric cars.

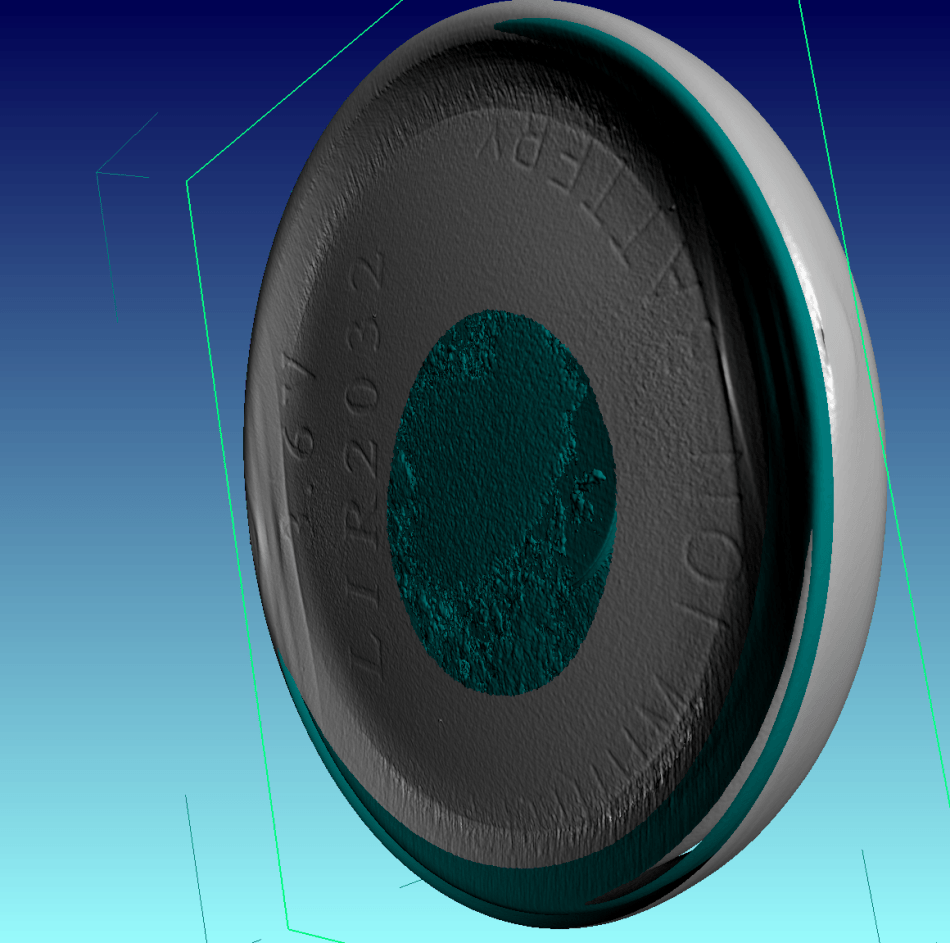

Full x-ray reconstruction of a coin cell supercapacitor. Credit: University of Washington

Full x-ray reconstruction of a coin cell supercapacitor. Credit: University of Washington

However, to realize these applications, supercapacitors require better electrodes, which help in connecting the supercapacitor to the devices that rely on their energy. It is necessary for these electrodes to be both cheaper and quicker in order to produce on a large scale and also to be able to charge as well as discharge their electrical load in a rapid manner. A team of Engineers at the University of Washington believe that they have developed a process for manufacturing supercapacitor electrode materials capable of meeting these stringent usage and industrial requirements.

The Researchers headed by Peter Pauzauskie, UW Assistant Professor of Materials Science and Engineering, published a paper in the July 17th issue of the journal Nature Microsystems and Nanoengineering. In this paper, they describe their supercapacitor electrode and the inexpensive, fast way they produced it. Their unique method begins with carbon-rich materials that have been dried into a low-density matrix known as an aerogel. On its own, this aerogel can behave as a crude electrode, however Pauzauskie’s team more than doubled its capacitance, which indeed is its potential to store electric charge.

These cost-effective starting materials, blended with a streamlined synthesis process, will minimize both speed and cost, two common barriers to industrial application.

In industrial applications, time is money. We can make the starting materials for these electrodes in hours, rather than weeks. And that can significantly drive down the synthesis cost for making high-performance supercapacitor electrodes.

Peter Pauzauskie, UW Assistant Professor of Materials Science and Engineering

Efficient supercapacitor electrodes are synthesized from carbon-rich materials that also comprise of a high surface area. The latter requirement is important due to the unique manner in which supercapacitors store electric charge. A standard battery stores electric charges through the chemical reactions taking place within it, while a supercapacitor stores and separates negative and positive charges directly on its surface.

Supercapacitors can act much faster than batteries because they are not limited by the speed of the reaction or byproducts that can form. Supercapacitors can charge and discharge very quickly, which is why they’re great at delivering these ‘pulses’ of power.

Matthew Lim, Co-lead Author, a UW Doctoral Student in the Department of Materials Science & Engineering

“They have great applications in settings where a battery on its own is too slow,” said fellow Lead Author Matthew Crane, a Doctoral Student in the UW Department of Chemical Engineering. “In moments where a battery is too slow to meet energy demands, a supercapacitor with a high surface area electrode could ‘kick’ in quickly and make up for the energy deficit.”

The team used aerogels to get to the high surface area for an efficient electrode. Aerogels are gel-like, wet substances that have gone through a special treatment of drying and heating in order to replace their liquid components with air or another gas. These methods help in preserving the 3D structure of the gel by giving it very low density and a high surface area. It is like removing all the water out of Jell-O with no shrinking.

“One gram of aerogel contains about as much surface area as one football field,” said Pauzauskie.

Crane produced aerogels from a gel-like polymer, which refers to a material with repeating structural units, developed from formaldehyde and various other carbon-based molecules. This guaranteed that their device, just like the currently available supercapacitor electrodes, would comprise of carbon-rich materials.

Lim earlier demonstrated that adding graphene to the gel instilled the resulting aerogel with supercapacitor properties. Graphene refers to a sheet of carbon that is only one atom thick. Crane had to enhance the performance of the aerogel and also make the synthesis process easier and cheaper.

In the earlier experiments carried out by Lim, the addition of graphene did not improve the aerogel’s capacitance. Aerogels were thus loaded with thin sheets of either tungsten disulfide or molybdenum disulfide. Today, both chemicals are extensively being used in industrial lubricants.

Both the materials were treated with high-frequency sound waves in order to break them up into thin sheets and then integrate them into the carbon-rich gel matrix. They were able to synthesize a fully-loaded wet gel within two hours, while other methods would take several days. The team then combined the dried, low-density aerogel with adhesives and another carbon-rich material to produce an industrial “dough,” which Lim could just roll out to sheets just a few thousandths of an inch thick. They cut half-inch disks from the dough and then arranged them into simple coin cell battery casings in order to test the effectiveness of a material as a supercapacitor electrode.

Their electrodes were fast, easy and simple to synthesize, and also contained a capacitance at least 127% greater than the carbon-rich aerogel alone.

Lim and Crane assume that aerogels loaded with much thinner sheets of tungsten disulfide or molybdenum disulfide — theirs were almost 10 to 100 atoms thick — would display a much better performance. However, they first wanted to prove that loaded aerogels would be cheaper and faster to synthesize, a vital step for industrial production. Fine-tuning is the next step.

The Researchers feel that these efforts can help improve science even outside the realm of supercapacitor electrodes. Their aerogel-suspended molybdenum disulfide could remain adequately stable in order to catalyze hydrogen production. It could also be possible to apply their method to trap materials quickly in aerogels to high capacitance batteries or catalysis.

Doctoral Student Xuezhe Zhou in the Department of Materials Science & Engineering was the Co-author. The research was executed with the help of Energ2 Technologies, a UW start-up company based in Seattle that was recently acquired by BASF. The UW and the Clean Energy Institute funded the research. Pauzauskie is also affiliated with the Fundamental and Computational Sciences Directorate at the Pacific Northwest National Laboratory.