.jpg) By Pritam RoySep 2 2022Reviewed by Susha Cheriyedath, M.Sc.

By Pritam RoySep 2 2022Reviewed by Susha Cheriyedath, M.Sc.In an article published in the journal Progress in Organic Coatings, researchers synthesized two different graphene nanosheets with distinct oxygen group localization to analyze their effect on the electrical characteristics of graphene/epoxy nanocomposite coatings.

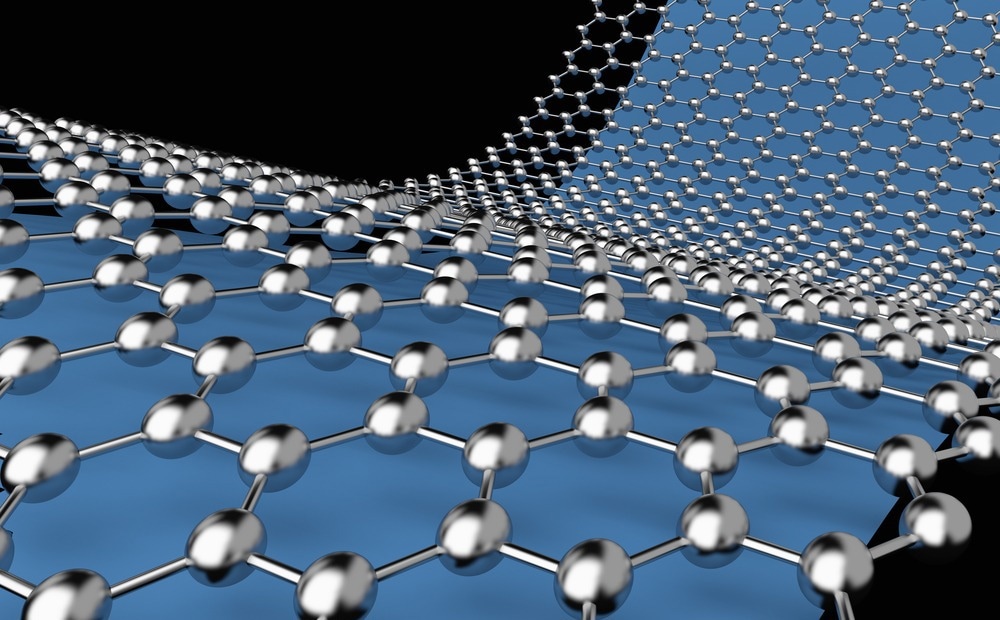

Study: Edge and Basal Functionalized Graphene Oxide Nanosheets: Two Different Behavior in Improving Electrical Conductivity of Epoxy Nanocomposite Coatings. Image Credit: Ambelrip/Shutterstock.com

Basal functionalized (B-GO) and Edge functionalized (E-GO) graphene nanosheets were synthesized using expanded graphite (EG) and graphite natural flakes (NG), respectively, as a carbon precursor. The next step involved distributing B-GO and E-GO into a waterborne epoxy matrix to fabricate polymer nanocomposite coatings.

B-GO demonstrated enhanced performance in network formation. Such a performance improvement could be attributed to the oxygen group similarity between the epoxy matrix and B-GO. Additionally, following the in-situ thermal reduction at 225 °C, the electrical conductivity value of polymer nanocomposite coatings was determined.

Despite E-GO having a greater intrinsic electrical conductivity than B-GO, the results showed that the polymeric coatings containing B-GO nanosheets exhibit higher electrical conductivity values than samples containing E-GO nanosheets. Hence, the findings revealed the B-GO nanosheets’ enhanced capacity to create an electrically conductive network within the epoxy matrix.

About the Study

Coatings were only applied in the past for aesthetic and protective purposes. However, coatings have developed and are now utilized in various applications to enhance several features, including electrical conductivity, corrosion resistance, optical properties, and surface wettability.

Hence, conductive polymeric coatings have drawn much attention because of their use in various fields, including solar cells, liquid crystal displays (LCDs), applications for electromagnetic interference shielding, and organic light-emitting diodes (OLEDs). (i) Copper nanowires and nanoparticles (Cu NWs and NPs), (ii) silver nanowires and silver nanoparticles (Ag NWs and Ag NPs), (iii) gold nanoparticles (Au NPs), (iv) aluminum (Al) and zinc oxide (ZnO), and other conductive metal nanoparticles have all been used as conductive fillers within the polymeric matrix.

However, the metallic nanoparticles’ poor corrosion resistance and weight limit their application in conductive coatings. In contrast, conductive carbon-based nanomaterials like carbon nanotubes and graphene have been developed as excellent candidates for substituting metallic nanoparticles in coatings to reduce coating weight and improve durability and corrosion resistance.

Graphene has become an excellent substitute for conductive materials in many applications because of its exceptional characteristics, particularly in flexible electrical devices. The hexagonal arrangement of the carbon atoms in graphene provides excellent mechanical characteristics, electrical conductivity, optical properties, thermal stability, and overall flexibility. Additionally, the conductive fillers can be integrated to host polymeric matrices using various fabrication techniques and can be applied to surfaces using multiple methods, including spin coating, dip coating, spray coating, and inkjet printing.

This paper presented a method for fabricating graphene oxide nanosheets with basal (B-GO) and edge (E-GO) functionalization that could assist the dispersion of nanosheets within the polymeric host without further chemical functionalization. The role of the edge and basal functionalization in enhancing the electrical characteristics was further demonstrated.

Observations

B-GO and E-GO nanosheets were produced via oxidation of the expanded graphite and natural graphite, respectively, using one equivalent weight of potassium permanganate with sulfuric acid. The graphite precursor was immersed in potassium permanganate and sulfuric acid solution and was heated to 35 °C. This heated solution was then kept at 35 °C for two hours.

The oxidation reaction was stopped by incorporating hydrogen peroxide and cold distilled water into the reaction mixture. Finally, the GO nanosheets were exfoliated with the graphite oxide precursor using a high-shear homogenizer in an alkaline medium.

The nature and inherent qualities of the integrated conductive fillers determined the electrical conductivity of the polymer nanocomposite coatings. At a specific concentration, referred to as the percolation threshold, a conductive channel was developed through the conductive fillers, transforming the insulative nature of nanocomposite coatings into an electrically conductive nature.

The nature and inherent qualities of the integrated conductive fillers determined the electrical conductivity of polymer nanocomposite coatings. Thus, high electrical conductivity fillers were essential to creating an electrically conductive polymer nanocomposite. In this regard, the electrical conductivity values for thermally decreased E-GO and B-GO were 18,833 ± 800 and 5830 ± 106 S/m, respectively, for one hour at 225 °C.

The findings showed that the predominant oxygen-containing groups in the B-GO sample were epoxy and hydroxyl groups. In contrast, the main functional groups on the E-GO graphene oxide nanosheets were carboxylic acid groups, most likely to be found in the E-GO sample.

Since the functional groups on the surface of B-GO graphene oxide and epoxy were more identical, B-GO graphene oxide epoxy nanocomposites had lower estimated percolation thresholds, leading to higher electrical conductivities.

Conclusions

This paper demonstrated the fabrication of basal and edge functionalized graphene oxide nanosheets. The findings showed that the interaction behavior between graphene oxide nanosheets and epoxy matrix fluctuated noticeably depending on the nature of oxygen-containing groups used.

The electrical conductivity findings showed that nanocomposite coatings comprising 1.5 wt% of B-GO had an electrical conductivity value equal to 0.5 S/m. In comparison, coatings containing 1.5 wt% of E-GO had an electrical conductivity value of 0.08 S/m.

Finally, the findings showed that incorporating B-GO graphene nanoplates over E-GO enhanced the ability to synthesize a three-dimensional network. The improvement in the ability to fabricate a three-dimensional network could be attributed to the functional group similarity of B-GO and the host epoxy matrix. Hence, although the inherent electrical conductivity of E-GO graphene nanoplates was higher, B-GO demonstrated enhanced performance.

More from AZoM: A Closer Look at Semiconductor Test Equipment

Reference

Rezvani-Moghaddam, A., Ranjbar, Z., Sundararaj, U., Jannesari, A., Dashtdar, A. (2022). Edge and Basal Functionalized Graphene Oxide Nanosheets: Two Different Behavior in Improving Electrical Conductivity of Epoxy Nanocomposite Coatings. Progress in Organic Coatings, 107143. https://www.sciencedirect.com/science/article/pii/S0300944022004404

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.