Reviewed by Lexie CornerApr 12 2024

Voids, or empty spaces, are present in matter of all sizes, from the astronomical to the microscopic. In this study, three-dimensional nanoscale gaps were revealed using advanced mathematical and microscopy theory. As a result of this development, many materials used in the home, in the chemical, energy, and medical sectors, and especially in the filtration area, are expected to perform better.

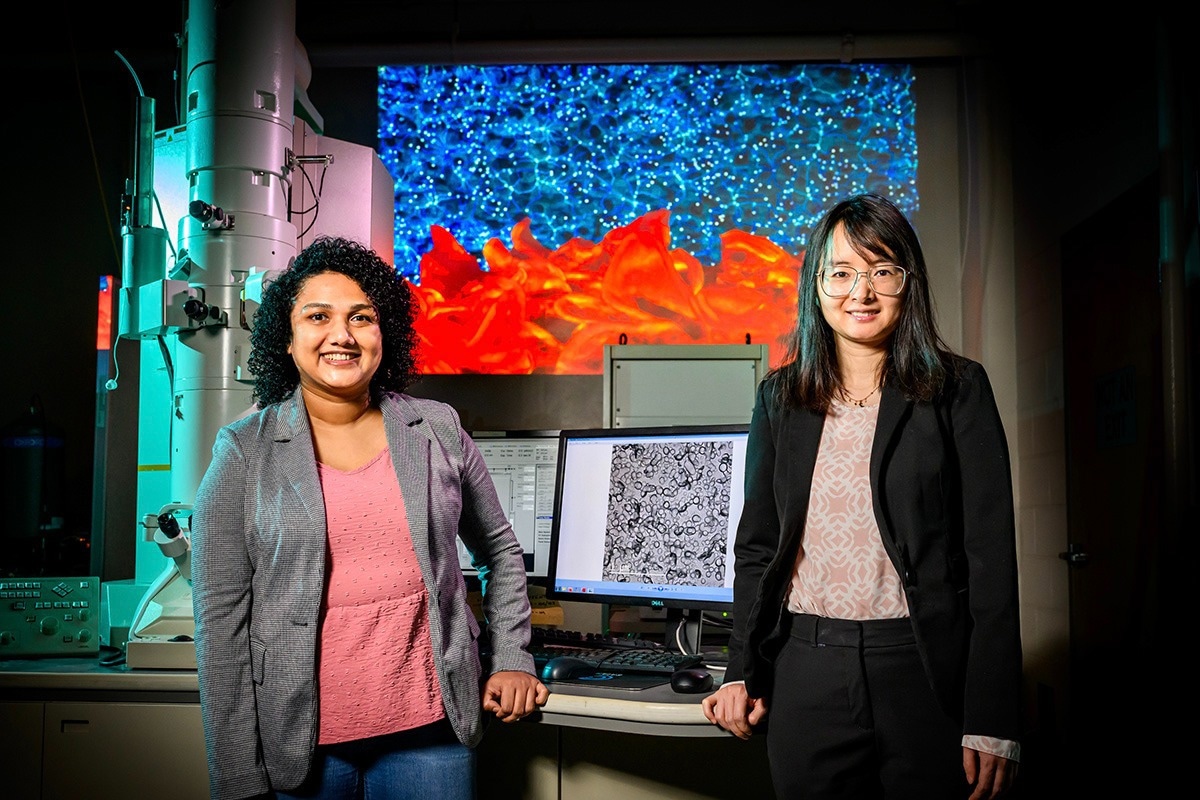

A new study by Illinois materials science and engineering professor Qian Chen, right, and chemistry graduate student Falon Kalutantirige emphasizes the importance of nanoscale empty space in everyday materials. The image in the background, titled “Beyond Nothingness,” was produced using computational modeling and portrays a magnified surface of a water filtration membrane as a mountainous landscape, with computational data points as the starry dark universe in the background. Image Credit: Fred Zwicky

A new study by Illinois materials science and engineering professor Qian Chen, right, and chemistry graduate student Falon Kalutantirige emphasizes the importance of nanoscale empty space in everyday materials. The image in the background, titled “Beyond Nothingness,” was produced using computational modeling and portrays a magnified surface of a water filtration membrane as a mountainous landscape, with computational data points as the starry dark universe in the background. Image Credit: Fred Zwicky

Magnification of common filters reveals that, while they appear to be one solid piece of material with consistent holes, they are actually made up of millions of randomly orientated tiny voids that enable small particles to flow through. In some industrial applications, such as water and solvent filtration, paper-thin membranes serve as barriers between fluids and particles.

The materials science community has been aware of these randomly oriented nanoscale voids within filter membranes for a while. The problem was that the complex structure of the membrane as a whole—which looks like nanoscale mountain ranges when magnified—was blocking our view of the void spaces. Because we could not see them, we couldn’t fully understand how they affected filtration properties. We knew that if we could find a way to see them, we could then figure out how they work and ultimately improve filter membrane performance.

Falon Kalutantirige, Study First Author and Graduate Student, University of Illinois Urbana-Champaign

The study, led by Illinois materials science and engineering professor Qian Chen and University of Wisconsin-Madison professor Ying Li, is the first to use materials science and a mathematical concept known as graph theory to image and map out the random placement of these voids in filtration materials. The findings were reported in the journal Nature Communications.

Building on a previous study that employed laboratory models, the researchers stated that the current study focused on significantly more sophisticated membranes used in industrial applications.

“The surfaces of the membranes we studied in this work look flat to the naked eye, but when we zoomed in using transmission electron microscopy, electron tomography, and atomic force microscopy, we could observe these voids nestled within these nanoscale mountainous landscapes that we call crumples,” Kalutantirige added.

However, the researchers need a method to quantify and map these traits to develop a quantitative predictive model and acquire a more comprehensive view of the membrane surfaces.

Mapping and measuring alone will work for materials with a regular or periodic structure, making it mathematically simple to scale up our models and predict how structural properties will influence the material’s performance. But the irregularity we observed in our study pushed us to use graph theory, which gives us a mathematical way to describe this heterogeneous and messy—but practical—material.

Qian Chen, Professor, University of Illinois Urbana-Champaign

Graph theory enabled the researchers to get a more comprehensive understanding of the filter membrane structure, leading to the discovery of a strong link between the distinct physical and mechanical features of random empty space and increased filtration performance.

Kalutantirige stated, “Our method is a very universal technique for describing materials. Many things we use in everyday life and science are not made of materials composed of repetitive uniform structures. So, the beauty of the method, I think, is that we can capture the ‘regularness’ of irregular structures.”

According to the researchers, this development will increase the performance of several next-generation porous materials, including drug-delivery polymers.

Chen further stated, “The title of this study hints at the concept of ‘beyond nothingness,’ and by that, we mean that these empty, void spaces are really important when it comes to developing the best filtration membranes. This work is only possible with our wonderful team of collaborators. Xiao Su helped us with the membrane performance testing. Emad Tajkhorshid, Charles Schroeder, and Jeffrey Moore worked with us on the synthesis and analysis of the polymer systems.”

The US Department of Energy, the Air Force Office of Scientific Research, and the National Science Foundation financed this research.

Chen also has affiliations with chemical and biomolecular engineering, chemistry, the Materials Research Laboratory, and the Beckman Institute for Advanced Science and Technology.

Jinlong He from UW-Madison, Hyosung An from Chonnam National University, Korea, and Illinois researchers Lehan Yao, Shan Zhou, John Smith, and Stephen Cotty also contributed to the study.

Journal Reference:

Kalutantirige, F. C., et al. (2024) Beyond nothingness in the formation and functional relevance of voids in polymer films. Nature Communications. doi:10.1038/s41467-024-46584-2