Heraeus continues to reduce the silver content per cell with the introduction of SOL205S, a back-side tabbing Ag conductor paste for mono and multicrystalline silicon solar cells. SOL205S requires less paste per cell than previous generations and maintains the advantage of printability ease and excellent cell adhesion. The paste is co-fireable with back-side aluminum and front-side silver pastes.

SOL205S is a Pb and Cd free material that has excellent solderability in both lead and lead-free solders.

Key Benefits

The benefits of SOL205S are:

- Reduced silver content

- Low paste consumption

- Excellent solderability

- High adhesion strength using Pb or Pb-free solders

- Ease of printability

- Cd and Pb Free

- Co-fireable with back-side Al and front-side Ag pastes

Low Ag Content with Improved Adhesion

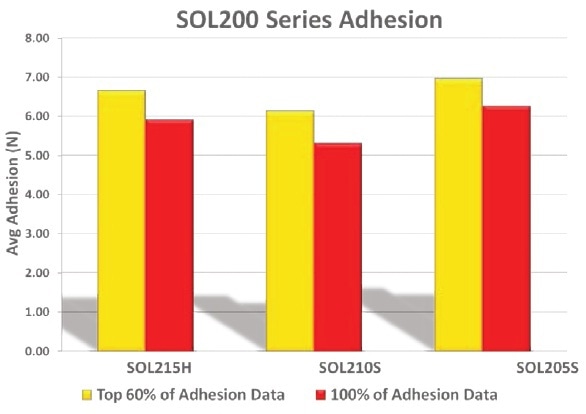

Heraeus SOL205S enables customers to reduce cost and at the same time maintains excellent performance. Reliability is also a factor that must be considered while selecting a back-side paste. SOL205S provides high adhesion for back-side tabbing applications. This reliability in adhesion gives high production yields, thereby lowering your manufacturing costs. Lower silver content must be complemented with high reliability. Figure 1 shows SOL200 series adhesion

Figure 1. SOL200 series adhesion

Lower Paste Consumption

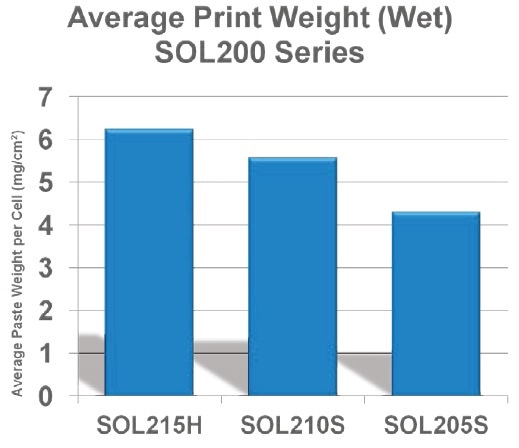

The SOL200 Series continues a downward trend in paste usage per cell. The Heraeus SOL205S requires less paste consumption per cell which will improve a cell’s cost position without sacrificing performance.

Lower silver content, reduced paste consumption per cell, high reliablity and improved performance makes the Heraeus SOL205S an ideal component to lowering the customer’s cells’ cost per watt. Figure 2 shows the average print weight SOL200 series.

Figure 2. Average print weight SOL200 series

Typical Properties

Viscosity

HBT Cone and Plate Viscometer (Brookfield)

- 70 – 130kcps

- CPE-51 spindle, @ 1RPM, 25°C

Solderability

- 96.5Sn/3.0Ag/0.5Cu

- Use with low solids, no clean flux

Solids

55 ± 1%

Processing Guidelines

Printing: Screen Parameter Recommendations

- 230 – 250 mesh, 36µm stainless steel wire

- 280 mesh, 32µm stainless steel wire

- 5 – 15µm emulsion

Other guidelines include:

- Drying: Typically dried in an IR dryer with set points of 250 – 300°C in less than 20 seconds or 150°C for 10 minutes in circulated air oven.

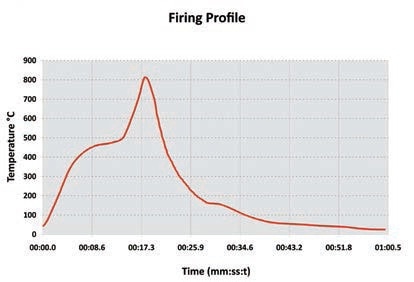

- Firing: IR Furnace with Actual Wafer

- Peak Temperature at 725 – 825°C.

- Thickness: 4 – 8µm (fired)

- Thinner: RV-372

- Storage: Store in a dry location at 5°C – 25°C.

The firing profile is shown in Figure 3.

Figure 3. Firing profile

About Heraeus Photovoltaics

The Heraeus Photovoltaics Business Unit is an industry leading developer and manufacturer of metallization pastes for the photovoltaic industry.

Heraeus has been a manufacturer of thick film pastes for over 40 years. Since 2008, we have been an innovative supplier to the photovoltaics industry, working with c-Si cell manufacturers to improve their cells’ efficiency for both conventional and advanced cell designs.

Heraeus have developed silver metallization pastes that have been integrated into commercially available technologies such as MWT, Double Print, Dual Printing, Selective Emitter, Back Side Passivation and N-Type Cells.

Heraeus have also expanded our capabilities and developed lower temperature processing pastes for Thin Film and other c-Si technologies.

Heraeus' goal is to improve our customers’ cell efficiency and reduce their cell’s cost per watt through our innovative paste design technology.

This information has been sourced, reviewed and adapted from materials provided by Heraeus Photovoltaics.

For more information on this source, please visit Heraeus Photovoltaics.