Raman spectroscopy is a unique technique that is often used in a range of applications such as forensic analysis, medical diagnostics, pharmaceutical manufacturing, and the food and agricultural industries.

This technique is applied for the molecular identification of unknown samples, however in recent years it is being extensively used in the characterization of polymers and plastics for both qualitative and quantitative analysis. Earlier, these materials were examined using burn tests, chromatographic separation, and wet chemical techniques which tend to damage the sample.

Today, Raman analysis has become the preferred method since it eliminates material preparation, inspects additives directly within polymers, and prevents errors that usually occur with other extractive chemical methods. This article discusses the benefits of using Raman spectroscopy for the Identification and characterization of polymers.

Raman Spectroscopy: A Simple and Non-Destructive Tool

Raman spectroscopy is a fast, simple and non-destructive tool and is suitable for examining polymers and additives. Raman spectroscopy measures rotational and vibrational frequencies of a molecule. A Raman spectrum is achieved by directing the light’s wavelength and collecting the resulting scattered light.

The combination of a portable, high resolution Raman spectrometer and advanced chemometric software from B&W Tek enables users to process their data with principal component analysis (PCA) or multivariate regression algorithms (MRA) in order to correlate all spectral data to the chemical properties of interest.

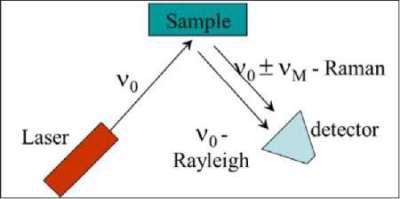

Through this technique, slight differences in the matrices can be utilized for instant analysis which otherwise would not be possible using conventional univariate techniques. Figure 1 illustrates the basic principles of a Raman analyzer, along with Raman spectra of five similar molecules. These Raman spectra can be clearly distinguished.

Figure 1. Principles of Raman spectroscopy, showing spectra of five similar molecules – Acetone, Ethanol, Dimethyl Sulfoxide, Ethyl Acetate, and Toluene.

Measurement on Brominated Flame Retardants in Plastics

The plastics industry uses the largest group of additives called brominated flame retardants (BFRs). However, most additives are very toxic and are being phased out in most parts of the world. These compounds are typically measured by chromatographic separation combined with mass spectrometry.

However, this technique consumes a significant amount of time and demands an extensive sample preparation process of chemical pre-treatment. Moreover, in order to analyze the sample, it has to be destroyed. Based on these reasons, Raman spectroscopy is becoming the preferred method of choice for sample analysis as it is nondestructive and takes only a short time to perform a full characterization of the material.

These capabilities can considerably benefit the plastics industry, since the need for a fast and cost-efficient measurement is important to cut down waste, ensure product performance, and reduce delays.

PolymerIQ System

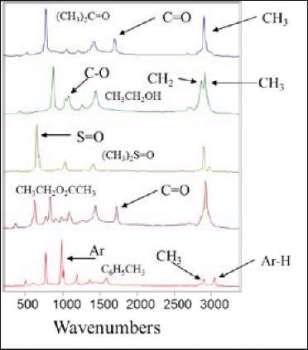

The PolymerIQ system is a unique tool that is capable of detecting the slightest difference between similar types of BFR additives. Figure 2 shows a spectral overlay of three different BFRs, such as penta-, octa- and deca-bromodiphenyl ether.

The spectral display on the right shows all the three brominated compounds separately, while the spectra on the left show these compounds together for comparison purposes, signifying the typical Raman shifts for the brominated aromatic molecules of each compound.

Figure 2. Raman spectral data for three brominated flame retardants, displayed together on the left and right

Measurement of Polymers

Polyethylene oxides are high molecular weight polymers that are generally utilized in the production of hydrophilic compounds and hydrogels that are typically found in thickeners, adhesives, absorbents, water-soluble films, and household and pharmaceutical products.

The known properties of polyethylene oxides and their regulatory acceptance have aided in extending the application of polymer to a range of drug delivery systems, especially for the intravenous injection of drug compounds. Hence, in the pharmaceutical industry, the increasing use of these types of polymers requires rigorous control measures.

Experiment and Results

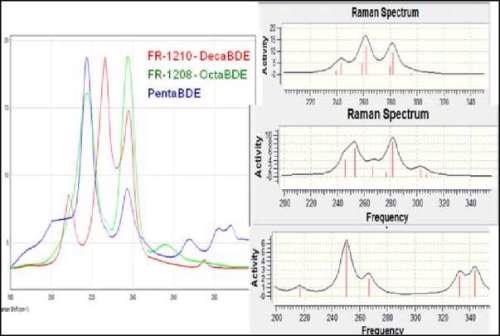

In this experiment, the PolymerlQ system was utilized to assess different batches of polyethylene oxides which had delivered both good and poor performance with respect to its drug delivery properties. Figure 3 illustrates multiple overlaid samples and the Raman spectra that appear similar to the human eye.

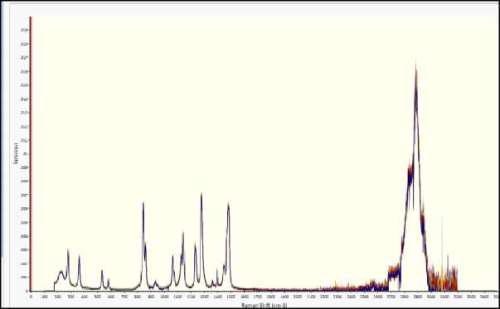

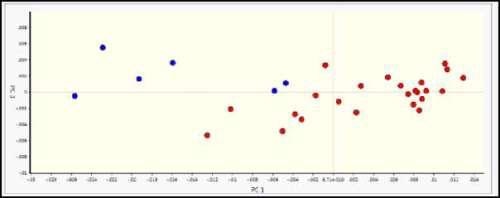

However, when PCA was applied to the Raman data, slight differences from the high quality spectra were detected by the software. In Figure 4, it can be seen that the good, higher viscosity samples (red) are differentiable from the bad, lower viscosity samples (blue).

Figure 3. Raman spectra of four similar polyethylene oxides samples

Figure 4. PCA analysis of Raman spectral data showing the bad, lower viscosity samples (blue) that are distinguished in PC space from good, higher viscosity samples (red).

Conclusion

From this study, it is clear that Raman spectroscopy provides a simple, fast and non-destructive method for analyzing different polymers and additives. The combination of high resolution Raman spectroscopy and sophisticated chemometric software is suitable to meet the rigorous demands of the plastics industry.

In addition, the PolymerIQ system offers an efficient and economical way of identifying and characterizing brominated flame retardant additives that are used in plastic manufacturing as well as excipients used as drug delivery compounds in the pharmaceutical industry.

This information has been sourced, reviewed and adapted from materials provided by B&W Tek.

For more information on this source, please visit B&W Tek.