High performance VICTREX PAEK polymers offer excellent versatility, reliability and design freedom for next generation electronic devices. Today’s electronic market is truly fast-paced and material advancement is critical. The quest for thinner, lighter and smarter mobile devices continues to push the limits of extreme engineering.

Electronic component design depends largely on demands for higher reliability, structural integrity and mobility and also concerns about the environment. Leading brands and OEMs specify Victrex high performance polymers including VICTREX PEEK and APTIV films to reach higher performance levels and to differentiate products with novel solutions.

The following short video outlines the topics covered in our recent webinar: Thinner, Lighter, Smarter: Why Mobile Devices Need High-performance Polymers.

Thinner, Lighter, Smarter On-Demand Webinar Intro

Trends in Mobile Devices

The present trends in mobile devices include the following:

- Portable media devices becoming thinner, lighter and smarter

- Increased daily use of portable products demands improved reliability

- Premium, clean look and feel

- Anodizing permits bold new designs along with durability of the chemical process-treated surface

- Sound quality and clarity are critical drivers for user satisfaction

- Rapid development and shorter lifecycles require quicker response from supply chain

Lightweight Polymers for High-Tech Solutions

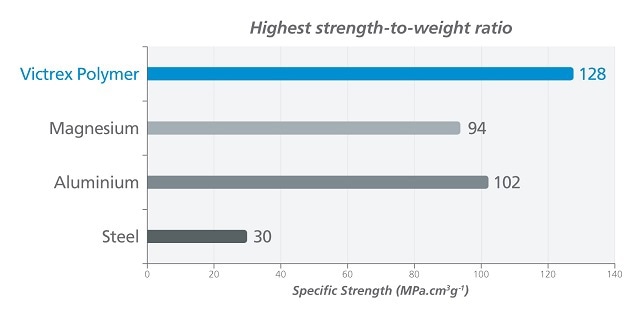

There are a large number of benefits offered by Victrex products that include high stiffness- and strength-to-weight ratio, wear, chemical and creep resistance, and processing flexibility as well as dimensional stability, low outgassing, radio transparency, low moisture absorption, and high temperature resistance. Regulatory and environmental advantages are also provided as PEEK polymers are validated in hot runner systems and meet the demands of lead-free solder processes readily. These high performance polymers are also fully recyclable as well as naturally flame retardant without the need for toxic additives.

Victrex PAEK-based products have a diverse range of electronics applications ranging from mobile device enclosures, switches, cameras, batteries, circuit boards and audio speakers to printers, copiers, sensors and connectors. Victrex products are ideal as a metal replacement or hybrid solution for enhanced performance and design.

APTIV Acoustics film technology

APTIV films offer excellent acoustic performance alongside unparalleled reliability. The nature and range of APTIV acoustic products offers acoustic engineers design flexibility where high quality sound is needed in small space applications.

Electromechanical Components

VICTREX PAEK overmoulded designs enable intricate geometries with watertight sealing for long term durability. The requirements are excellent modulus and strength, adherence to metals, surviving anodizing, dielectric stability and radio translucent.

Advantages of Victrex Polymers

Enable advanced look and feel:

- Polymer withstands anodising and dye process for durable metal colors

- Black color film and tapes with matte/gloss options

Streamline manufacturing:

- Rapid cycling, hot-runner or closed-loop recycle to reduce waste

- Multi-part overmoulding onto metals for uni-body construction

- Adhesive-less joining with laser weld (moulded part-to-film)

Design to the extreme:

- Optimise design, synergise with metal, then anodise

- Hybrid structures with localized reinforcements

- Best combination of stiffness, strength and toughness for thin-wall molding

Metal Hybrid Solution

Figure 1 shows the strength-to-weight ratio of Victrex Polymers when compared with metals such as magnesium, aluminium and steel.

Figure 1. Highest strength-to-weight ratio.

This information has been sourced, reviewed and adapted from materials provided by Victrex.

For more information please download the full brochure from Victrex.