Throughout the analytical process, it is important for modern analytical laboratories to identify uncertainties. X-ray fluorescence and borate fusion was required to detect key elements in ores, cements and several other matrixes. Bias and drifts coming from the burner position, the fusion technique, the mold effect and the change of fusion instrument are difficult to quantify and assess.

Fusion Monitor by Claisse

The fusion monitor that Claisse has developed was introduced as a new quality control product to determine and validate the correction of drifts and biases related to the fusion technique.

The Fusion Monitor as shown in Figure 1 for XRF analysis has been available for a couple of years. It allows quick, easy and error-free monitoring of the complete fusion analytical process for XRF analysis.

Figure 1. Fusion Monitor

International standards (such as ASTM C-1141 and ISO/DIS 29581-22) and internal laboratory control targets often determines quality control criteria for cements, iron ores and other materials.

These standards have stringent accuracy and precision requirements. In order to meet standards, sample preparation protocols and analytical methods must originally be adjusted.

With the help of borate fusion sample preparation with XRF spectrometry is now needed for the precise analysis of common and new matrixes in present day laboratories.

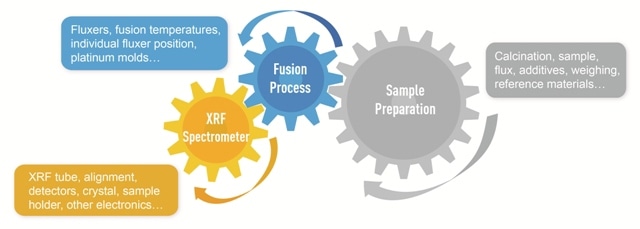

However, certain variables in the lab may cause precision and accuracy to drift away from original values. As shown in Figure 2, a typical sample preparation can be classified by fusion and XRF process into three steps.

Figure 2. Typical sample preparation

There are three steps in sample preparation:

- The first step is the preparation of the sample which includes calcination of the sample, the weighing and the mixing.

- The fusion process itself is the second step.

- The last step is the analysis of the prepared sample on the XRF spectrometer.

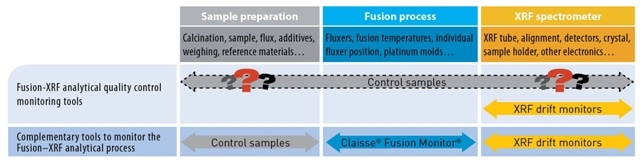

Stable fortified glass disks to assess and correct XRF calibration drifts (XRF drift monitors) are commonly available. These tools do not determine imprecision, inaccuracies and drifts related to the other steps of the analytical process.

Control samples are used regularly to make sure that the complete process is controlled. The sample will help in determining if there is a bias during the complete analytical process. Certified reference materials (CRMs) can be used for overall method quality monitoring, however this practice is time consuming and costly.

Using a sample itself to perform drift monitoring is not accurate because the material’s composition can be changed over time. As shown in Figure 3, using the Fusion Monitor chemical compound will help monitoring the bias coming from the fusion process itself, thus allowing the control sample to focus on the bias from sample preparation and the XRF drift monitor to correct any error coming from the XRF spectrometer.

Figure 3. Monitoring the bias coming from the fusion process

Description

The Fusion Monitor is a quality control product that has been developed for a easy, rapid and proactive quality assessment and monitoring of the fusion process and platinum ware. It is not a RM or a CRM. It comprises fused, homogenous and round glassy beads composed of lithium borate flux, of a non-wetting agent and of a stabilized matrix (cement for example).

The sample matrix is secured from alterations since it is pre-fused in borate flux. The Fusion Monitor is easy to use and can be fused directly from the bottle. This is different from the sample preparation step and it can be manipulated with a v-shaped spatula, just like regular flux.

The Fusion Monitor and the fluxes that Claisse developed, share the same characteristics (hygroscopic, very stable, high density (1.4g/cm3), high fluidity, low water content, etc.

There is no use of weighing the sample and the flux as both of them are merged in the same product. Using the Fusion Monitor therefore improves the preparation process since it saves preparation time.

Manipulation errors are thus avoided. In order for a Fusion Monitor glass disk specimen to be prepared, the operator simply has to put a certain amount of the Fusion Monitor into a platinum crucible and run his routine analytic process. The preparation takes just seconds as there is no requirement for precise weighing.

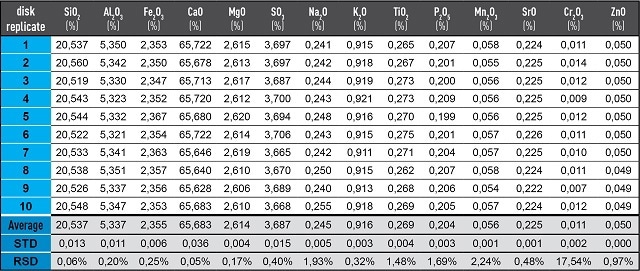

Fusion Monitors are available in large batches in which the sample matrix is homogeneously distributed. Table 1 shows the analysis of 10 samples from a typical batch of Type C Fusion Monitor. The Fusion Monitor glass disks were prepared using a M4™ fusion instrument.

The Fusion Monitor chemical compound is available for a wide range of applications such as cement, iron ores, ceramics and catalysts.

Table 1. Analysis of 10 samples from a typical batch of Type C Fusion Monitor

In order to bridge a missing link in the quality control process for fusion applications for XRF analysis, the Fusion Monitor quality control product was designed.

It is beneficial for laboratories performing fusion for XRF analysis and that are interested in following changes in the fusion instrument, platinum ware, temperature and fusion positions on a given instrument,.

Scope of Use

Since it is homogenous and stable, the matrix matched Fusion Monitor is suitable for assessing and validating the precision of the fusion procedure as well as its precision (drift) over time. In combination with ideal laboratory practices, the Fusion Monitor can help diagnose the root cause of analytical difficulties and validate corrective actions.

As it is based on comparison, the Fusion Monitor can be used irrespective of flux brand and composition used for routine analysis. The measurement obtained from a given Fusion Monitor preparation is compared to a reference value obtained by the preparation of Fusion Monitor specimens in an initial set of conditions (time, mold, fusion instrument and position, etc.).

As Claisse developed the Fusion Monitor, it may be utilized even if the sample to flux ratio of the routine samples differs from the specifications of the quality control compound. For instance, the mold effect can produce a significant analytic bias and is another example of the utility of the Fusion Monitor developed by Claisse.

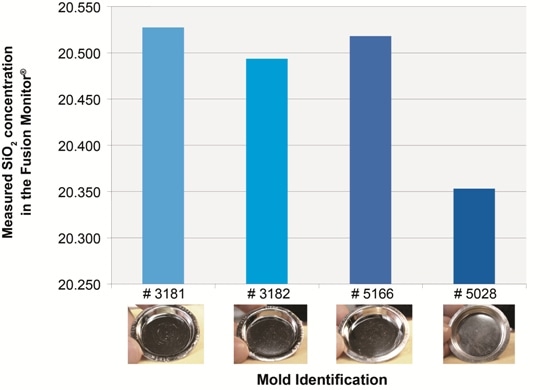

This impact is due to inconsistencies on the mold surface (warping and scratches for example). This bias can be easily monitored and determined by the Fusion Monitor. Figure 4 shows how the Fusion Monitor chemical compound was used to determine the mold effect.

Figure 4. How fusion monitor chemical compound used to determine mold effect

Four different molds (serial numbers 3181, 3182, 5166 and 5028) were used for preparing Fusion Monitor glass disk specimens (n=2). The mean SiO2 measurement obtained while using mold 5028 is clearly lower than for the three other molds.

This shows that mold 5028 requires reshaping and polishing before being reintroduced into production. Using the Fusion Monitor helps in determining the mold effect so that polishing and reshaping can be performed only when necessary, thus saving time and uncertainties.

Conclusion

The Fusion Monitor quality control compound is suitable for quality assessment of all aspects of the fusion analytical process. Its homogeneity and stability characteristics are ideal for monitoring bias and accuracy drifts over time.

This quality control compound is a new approach in the fusion and XRF scientific community to control analytical drift and identify bias between fusion instruments, burners, or molds. In combination with ideal laboratory practices, the Fusion Monitor is a powerful tool to achieve modern quality control goals.

This information has been sourced, reviewed and adapted from materials provided by Claisse.

For more information on this source, please visit Claisse.