Precious metal mining involves removing ore from the ground and subjecting them to a number of sample preparation methods for the extraction of the desired metals. Fire-assay is a widely used method for separation of metals from their ores, leaving behind a matrix-free "button" of the metals of interest. This is followed by dissolution of the resultant button in the appropriate acids for subsequent analysis.

Since the amount of sample utilized in the sample preparation is known, it is possible to determine the metal concentration in the ore from the analytical results. Flame atomic absorption (AA) spectrometry is typically used to perform these analyses owing to its cost effectiveness, ease of operation, robustness, and analytical speed.

This article discusses the advantage of using the PerkinElmer PinAAcle™ 500 Flame AA spectrometer to analyze precious metals in simulated digested precious metal buttons, with special focus on the accurate measurement of the low levels.

Experimental Procedure

A PerkinElmer PinAAcle™ 500 Flame AA spectrometer equipped with a 10 cm burner head was used to perform all analyses under the conditions listed in Table 1. A high sensitivity nebulizer without a spacer was employed to introduce all samples and standards by means of self-aspiration. Optimizing the gas flow rates resulted in a steady signal with maximum sensitivity.

Table 1. PinAAcle 500 AA spectrometer instrumental conditions

| Parameter |

Gold (Au) |

Palladium (Pd) |

Platinum (Pt) |

Copper (Cu) |

Silver (Ag) |

| Wavelength (nm) |

242.80 |

244.79 |

265.94 |

324.75 |

328.07 |

| Slit (nm) |

0.7 |

0.2 |

0.7 |

0.7 |

0.7 |

| Lamp |

HCL |

HCL |

HCL |

HCL |

HCL |

| Air Flow (L/min) |

4.40 |

4.40 |

4.40 |

4.40 |

7.80 |

| Acetylene Flow (L/min) |

1.58 |

2.02 |

2.02 |

1.86 |

2.02 |

All analyses used a three-second integration time and three replicates. Roughly 15% aqua regia (gold, palladium, platinum) or 2% HNO3 (copper, silver) was used both for standard preparation and as a matrix to simulate a button sample dissolution subsequent to fire-assay sample preparation.

Experimental Results

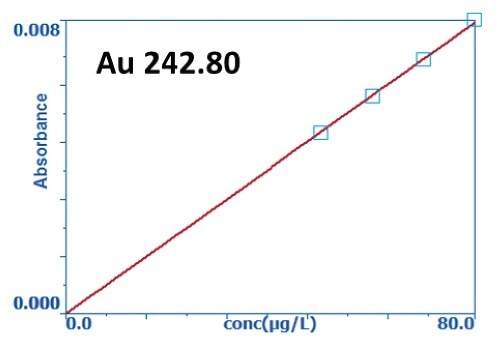

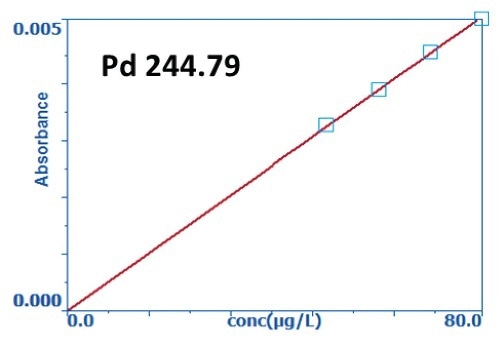

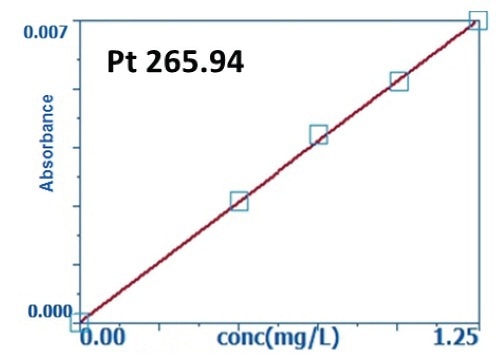

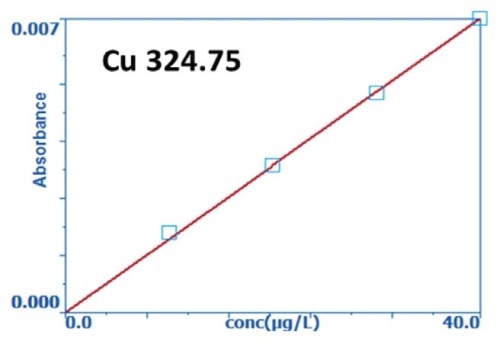

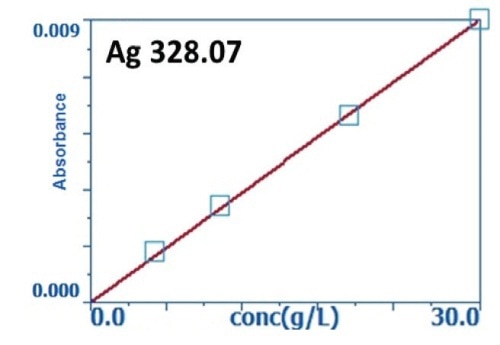

Low-level calibration curves with regression values > 0.999 were established to assess the ability of performing accurate low concentration measurements. The lowest standards were those with absorptions higher than the blank and relative standard deviations (RSDs) less than 5%. It is possible to measure lower concentrations for each element, but the RSDs would be higher than 5% due to statistics associated with small numbers.

The calibration standards and the resulting calibration curves are given in Table 2 and Figure 1, respectively. Measuring a standard at the mid-point of each calibration curve assessed the accuracy of the measurements. Table 3 shows the corresponding results.

Figure 1. Low-level calibration curves for gold, palladium, platinum, copper, and silver.

Table 2. Low-level calibrations

| Element |

Calibration Standards (µg/L) |

Calibration Type |

| Au |

50, 60, 70, 80 |

Linear Through Zero |

| Pd |

50, 60, 70, 80 |

Linear Through Zero |

| Pt |

500, 750, 1000, 1250 |

Linear Through Zero |

| Cu |

10, 20, 30, 40 |

Linear Through Zero |

| Ag |

5, 10 20, 30 |

Linear Through Zero |

Table 3. Mid-level standard quantitative read back

| Element |

Standard (µg/L) |

Read-Back (µg/L) |

% Recovery |

| Au |

65 |

67.7 |

104 |

| Pd |

65 |

69.2 |

106 |

| Pt |

850 |

836 |

98 |

| Cu |

25 |

24.1 |

96 |

| Ag |

15 |

14.5 |

97 |

Conclusion

The results clearly demonstrate the capability of the PinAAcle 500 Flame AA spectrometer to perform accurate measurements of low-level precious metals in matrices resulting from the preparation of ore samples with the fire-assay method.

Sample analysis is simplified, thanks to the Syngistix Touch™ software operated from the large touchscreen display of the PinAAcle 500. However, if more flexibility is required, Syngistix™ for AA software can be run from the PinAAcle 500’s on-board computer. With this full-featured software, greater flexibility can be achieved for method development, reprocessing of off-line post-analysis data, and reporting.

Along with these improved software features, the PinAAcle 500 has been designed for use in corrosive environments by incorporating acid-resistant coatings on the flame shield and instrument boards. These qualities make the PinAAcle 500 Flame AA an ideal tool to perform precious metal measurements in a mining atmosphere.

This information has been sourced, reviewed and adapted from materials provided by PerkinElmer.

For more information on this source, please visit PerkinElmer.