Single-detector systems, also known as conventional gel-permeation chromatography (GPC), feature a refractive index (RI) detector, and are used for making molecular weight measurements by comparing the elution time of a sample against the standards of a known molecular weight. Multi-detector GPC is an advancement of single-detector systems.

Traditional single-detector systems are employed in many applications, such as preparation of polysaccharides, development of synthetic polymers, manufacture and QC, blending, and grading. Single-detector systems are very popular, thanks to their robustness, reproducibility, repeatability, simplicity, and accessibility. However, in the past few years, this technology has been improved considerably, and additional detectors provide significant amounts of information. Light scattering detectors such as LALS, RALS or SEC-MALS are capable of measuring both molecular weight distribution and absolute molecular weight with excellent precision. Multiple concentration detectors enable compositional analysis of copolymers, and viscometers help in determining molecular structure and branching. Keeping these advantages in mind, this article shows the top 10 reasons for using a sophisticated multi-detector GPC system.

Absolute Molecular Weight

A major restriction of using the standard GPC/SEC technique is the way molecular weight is measured. Given that molecular weight originates from retention volume and from a comparison with molecular weight standards, the quantified results will be precise only if the standards are of the same material as the sample. Traditional calibration overlooks the changes in structure, sample type, branching and chemistry/composition. Figure 1 shows a multi-detector GPC system, OMNISEC.

Figure 1. No polymer characterization laboratory is complete without an advanced multi-detector GPC system such as OMNISEC.

Modern polymers entering the market often lack the required standards. Measurement of a relative molecular weight is only sufficient when ensuring that a pair of production batches are identical, but using a light scattering detector ensures that all molecular weight measurements are precise, regardless of the polymer being determined.

Structural insights

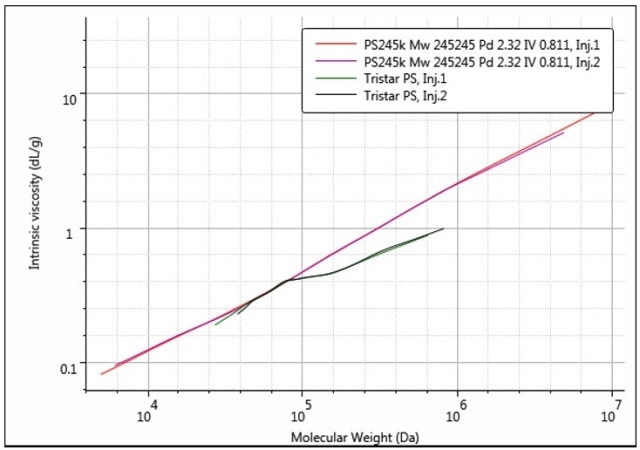

The Mark-Houwink Plot (molecular weight versus intrinsic viscosity) or Conformation Plot (molecular weight versus Rg) is perfect for studying polymer structures (Figure 2). These tools are useful when comparing and contrasting molecular size or density as a function of molecular weight, both of which are associated with structural changes within a sample.

Figure 2. A Mark-Houwink plot easily distinguishes between linear and branched samples.

If a branched polymer is being produced, then these plots would aid the viewing and measuring of the level of branching in a specified sample. If a natural polymer or polysaccharide derivative is being used as a viscosity modifier in creams or foods, the degree of substitution will considerably affect the performance of a product, and cannot be defined using traditional techniques or bulk measurements of viscosity. Also, this can be viewed with a Conformation or a Mark-Houwink Plot. As soon as target Mark-Houwink values have been detected, production of the polysaccharide product can be controlled in a better way, thus improving the quality and value of a product.

Copolymer Composition

Copolymers can differ with respect to molecular structure, weight and composition. In the case that a copolymer is changing both molecular weight and composition, then the molecular weight distribution acquired from standard measurements will fail to have a representative shape or representative values for the molecular weight.

A multi-detector GPC system containing two concentration detectors can utilize the varied responses of individual detectors for individual components to deconvolute each component’s concentration, and subsequently work out the molecule’s dn/dc at each data slice. This helps in the precise measurement of molecular weight over the entire distribution, irrespective of whether the molecule is changing composition or structure. RI and UV are the standard concentration detectors, but this technique needs at least one of the components to be a chromophore. Nevertheless, this approach opens up a wide range of applications.

Information

Multi-detector GPC could potentially be one of the most data rich methods. In fact, a single experiment is capable of determining a polymer's molecular weight, molecular weight distribution and moments, intrinsic viscosity, polydispersity, radius of gyration, hydrodynamic radius, Mark-Houwink parameters, branching frequency, branching number, UV absorbance, polymer concentration, dA/dc, dn/dc, absorbance spectra, and recovery. With large amounts of data available from an individual system, sophisticated GPC substantiates its value for both existing and future characterization needs.

Molecular Weight, Independent of System and Setup

The molecular weight of a sample is independent of the system, in addition to being independent of the retention volume of a sample compared with the molecular weight standard. In a traditional setup, factors like flow rate, column set, pump performance, and run temperature can influence the quantified molecular weight. In other words, if molecular weight is measured at multiple places on multiple systems, or on varied days, unexplained variations are observed. It may be due to the systems themselves even if they are regularly validated and serviced. However, in a multi-detector setup, the quantified molecular weight does not rely on these things, thus ensuring greater consistency between batches and instruments.

More Easily Identify Experimental Issues

The single-detector GPC is known for its excellent robustness, and consistently provides the same results all the time. However, a major drawback of this system is that it is characterized by a number of issues:

- Improper sample dissolution leads to inaccurate reporting of molecular weight, resulting in potential damage to the system and columns

- Interaction of the column and sample results in later elution times and inaccurate reporting of the molecular weight

- The presence of aggregated material in small quantities could be masked from a stand-alone concentration detector

Any of the above issues can lead to inaccurate results and thus affect the quality of products. Such issues can be identified with a multi-detector system, which guides users to take action to reduce them, thereby reducing the occurrence of quality problems and their associated costs.

Time and Cost Efficient

Standard calibration consumes a significant amount of time. Each time a system setup is modified, an entire set of standards have to be run to develop the calibration curve. However, in multi-detection, only a single-calibration standard is required. All normalization factors, detector calibration constants, offsets, and band broadening factors are measured in one step, and sample measurement can be immediately started, thus resulting in faster measurements and faster testing.

Because What You Don't Know CAN Hurt You

Repeatability is one major benefit of using a standard calibration, single-detector system, but this repeatability is only possible because a small amount of data can be captured. There could be underlying variations which would not be perceptible. For example, standard calibration is not capable of differentiating between a branched sample and a linear sample of slightly higher molecular weight. In the case that there are similar polymers from similar syntheses, which exhibit distinctive properties, this could be attributed to the inability of the traditional system to differentiate the underlying variations controlling the product's quality. Such outcomes would lead to quality issues and unhappy customers, thus affecting the profitability. In contrast, a multi-detector system detects these issues and helps in producing a quality product all of the time. This translates into a higher value product and a higher quality.

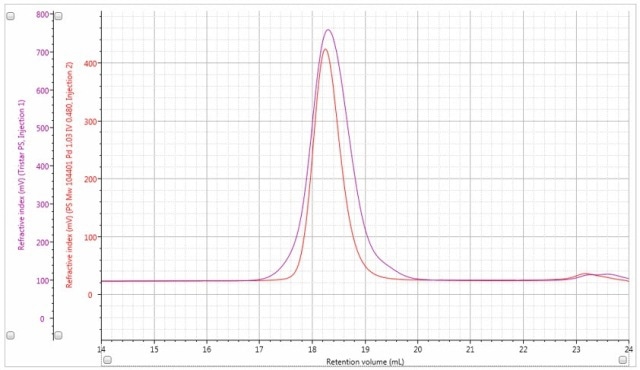

Figure 3 displays overlaid RI chromatograms for linear and branched polystyrene. The latter sample is characterized by higher molecular weight, but its branching does not alter its size. As a result, both samples elute at the same time. In contrast, standard techniques would record these as having identical molecular weights, but the real molecular weight change and branching could drive the polymer's properties beyond the preferred specifications.

Figure 3. Overlaid RI chromatograms for linear (red) and branched (purple) polystyrenes. Conventional measurements are unable to see the significant differences in molecular weight and structure.

Your Competitors are Already Using These Techniques

Every year, a countless number of papers are published citing chromatography, light scattering, multi-detector SEC, multi-detector GPC, or SEC-MALS. Such papers are published by scientists who apply these methods to optimize their own productivity. By employing multi-detector techniques, they are staying at the forefront of polymer characterization studies.

In fact, many companies are increasingly using multi-detection to assess samples from bulk polymers like polyolefins, polystyrene, PET and PVC to renewable polymers such as hyaluronic acid, lignins, pectins, alginates, and cellulose derivatives. Both in QC departments and online, multi-detection systems have been established to assure the highest quality product from research and development phase through to the production phase.

Because You Can't Afford Not To

With stringent margins and strong competition to market, improved characterization and better control of polymers and their properties through enhanced production control would translate into a better product. This means less waste, fewer quality issues, and better control of production costs. In case polymers are being characterized for use in different types of formulations, then grading and quality checking of raw materials would demand a greater level of certainty to ensure that the end product is within the desired specification. This reduces the risk of low quality raw materials, which could affect an entire production batch, thus saving time and money in this process.

A multi-detection experiment provides more precise results in a faster way. Irrespective of the industry, the optimum way is to have the best data from a sophisticated system, and this could be achieved by investing in a suitable multi-detection system.

Conclusion

Whether developing new polymers and/or polymerization methods in research, or producing polymers or polymer-containing formulations in the industry, multi-detection systems provide a number of benefits compared to a single-detector system. The above-mentioned points provide insight into the nature of the polymer being characterized. Ultimately, this translates into improved control and product quality, more reliable product quality and happier customers.

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.