Various factors need to be considered when attempting to obtain an accurate measurement of a sample’s particle size distribution. Using a reliable, highly accurate sizing instrument, and dispersing the sample successfully into its constituent primary particles, are the key factors amongst them.

For efficient sample dispersion, care must be taken to choose the appropriate dispersing medium, additives and surfactants. Also, a good dispersion can be ensured by using ultrasound for the physical separation of particles. Attaining the appropriate dispersion conditions for a specific sample is a fine balance.

The instrument often reports a skewed particle size as the particle size distribution measured by it includes any particle agglomerations in the sample. Conversely, breaking up or milling of the primary particles may occur under harsh dispersion conditions. This is also detrimental as it is unrepresentative of the sample under analysis.

Identifying the point at which full dispersion of the agglomerated particles occurs without milling the primary particles is the area of focus of the particle sizing method development specialist. Microscopy is traditionally used for off-line observation of an aliquot of the sample off-line, to determine the occurrence of milling or dispersion. This article discusses the application of the Hydro Sight imaging accessory to perform this process in-line.

Using Hydro Sight to Determine Shape Change

The experiment involved preparation of urea-formaldehyde, which is a multipurpose resin that contains needle-like particles, for measurement on a Mastersizer 3000 laser diffraction system. A Hydro MV wet dispersion accessory, equipped with a Hydro Sight connected in-line, was coupled to the Mastersizer. Sample addition continued until reaching the required laser obscuration, at which the Hydro Sight analysis was initiated in conjunction with the laser diffraction measurement.

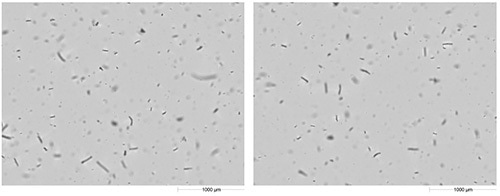

Figure 1 illustrates the analysis of the images of the sample traversing the system by the Hydro Sight during the laser diffraction measurement. The Hydro Sight collects a size distribution and an elongation distribution of the particles from these images. It is possible to capture data at any point, recording the current distribution in conjunction with a representative image frame. The example showed here involved acquisition of the results concurrently with the laser diffraction measurement.

Figure 1. Example images of urea-formaldehyde taken with Hydro Sight.

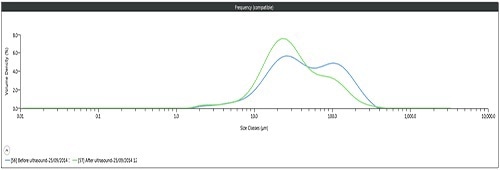

After the initial measurement, the application of ultrasound facilitated further sample dispersion. The subsequent particle size distribution measurement by the Mastersizer revealed a reduction in Dv90, along with an increased level of fines (Figure 2). This finding is in agreement with the sample dispersion and removal of agglomerated particles. However, some milling may have occurred because the particles had a needle-like shape.

Figure 2. MS3000 PSD before ultrasound (blue) and after ultrasound (green).

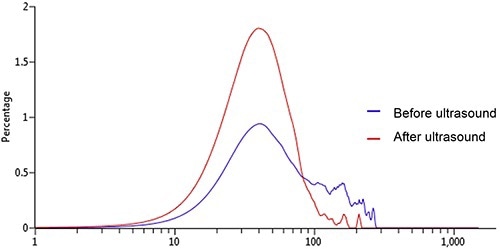

The distributions were reset when a result was captured on the Hydro Sight, making them representative of the sample subsequent to the application of ultrasound. This was followed by acquisition of the Hydro Sight result upon completion of the laser diffraction measurement by the Mastersizer. Figure 3 compares the size distributions measured by the Hydro Sight before and after the application of ultrasound.

Figure 3. Hydro Sight PSD before (blue) and after ultrasound (red).

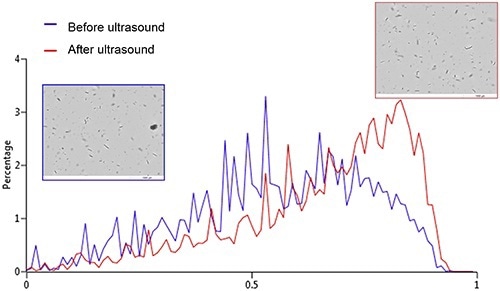

The distributions produced by the Hydro Sight indicate the same change in size distribution after the application of ultrasound, as measured by the Mastersizer. The shape information that can be obtained from the images analyzed is the real benefit of using the Hydro Sight. As can be seen in Figure 4, an increase in particle elongation post-ultrasound is revealed by the elongation distributions acquired over the same image frame sequences, as anticipated for dispersion of agglomerated urea-formaldehyde into single particles.

Figure 4. Hydro Sight elongation distribution before (blue) and after ultrasound (red).

The increase in particle elongation is not in line with the theory that the sample could be milled by the ultrasound, but corroborates the dispersion of the needle-like particles. Therefore, the use of the Hydro Sight in-line with the Mastersizer 3000 facilitates simultaneous evaluation of the sample dispersion and size measurement in the course of the dispersion process. This, in turn, eliminates the need for an offline analysis.

Conclusions

This article has demonstrated the application of the Hydro Sight imaging accessory in-line with the Mastersizer 3000 to rapidly and conveniently determine whether the urea-formaldehyde sample is dispersed or milled upon application of ultrasound.

The Hydro Sight captures images during the circulation of the sample through the Mastersizer 3000 system, enabling basic shape data to be resolved and monitored throughout the dispersion process, and complementing the size information acquired by the Mastersizer. The increase in elongation determined post-ultrasound corroborates that the needle-like sample is not milled, but dispersed, thus avoiding the need for off-line microscopic evaluation of the sample dispersion.

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.