Roughly 35 million tons of vinyl chloride monomer (VCM) are produced annually, most of which is used for manufacturing polyvinyl chloride (PVC). VCM is formed when 1,2 dichloroethane or ethylene dichloride (EDC) is cracked at high temperature and pressure:

Vinyl chloride is a toxic, flammable and carcinogenic compound. Levels of VCM and EDC need to be monitored by VCM users and manufacturers in their workplaces. The OSHA limit for VCM is set at 1ppm on an eight-hour basis; 50ppm is the equivalent limit for EDC.

Process Insights®MAX300-IGTM Spectrometer

The large 19mm diameter rod quadrupole mass spectrometer from Process Insights has much higher sensitivity than smaller quadrupoles and magnetic sector mass spectrometers. As a result, Process Insights’ spectrometer can reliably monitor even trace amounts of VOCs, thus eliminating the triggering of expensive false alarms.

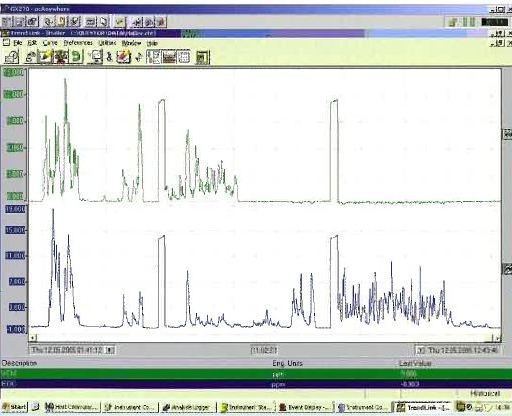

Figure 1 illustrates the trend displays of VCM (shown in green) and EDC (shown in blue) during an issue in a plant. The trend display clearly shows that the Process Insights systemVCM will not be triggered when the EDC level is high.

Figure 1. Trend display of VCM and EDC.

The key features of Process Insights®MAX300-IGTM Spectrometer include:

- Detects VCM and EDC levels as low as 20ppb, in comparison with current OSHA time weighted average limits of 1ppm and 50ppm, respectively

- Capable of analyzing a single stream within 10 seconds

- Capable of monitoring 80 sample points within 15 minutes

- Avoids false alarms and readings by accurately compensating for interference between EDC and VCM using Process Insights’ Questor 5 software

This information has been sourced, reviewed and adapted from materials provided by Process Insights - Mass Spectrometry.

For more information on this source, please visit Process Insights – Mass Spectrometers.