In any polymer plant, process gas analysis is important to control and optimize the manufacturing process of polypropylenes and polyethylenes. In plant control systems, the content of the reactor gas streams not only indicates the manufacturing efficiency, but also provides the required data to modify process variables. Polymer manufacturers need to change their product formulations on a constant basis, and hence, during process transitions, the rate of inlet gas analysis becomes critical.

Image Credit: Shutterstock/AppleEyesStudio

In order to ensure a real-time measurement, a MAX300-IG process control mass spectrometer was used to track polyethylene reactor gas. The data obtained was evaluated against a simultaneously measurement carried out using the standard process gas chromatography (GC) technique. The precision of the MAX300-IG was confirmed through the GC data, and additional comparison demonstrated that the mass spectrometer gives a more complete analysis rapidly.

Production of Polyethylene and Polypropylene

Typically, polypropylene and polyethylene are produced through polymerization of the gaseous monomer along with additives of accurately specified concentrations to create the preferred branching and density in the end product. Depending on market conditions, production plants are capable of producing a wide range of polymeric materials. In the plant's mode of operation, such differences typically happen during a semi continuous process, with certain changes occurring to the gas-phase reactant composition that ultimately determines the end product. Consequently, a transition period takes place between individual batches as the contents of the reactor switch from the original formulation to the composition that will produce its replacement.

A batch is capable of running continuously for hours or a few days, and yields low-value material that does not meet the desired specification. The reactor sample is subjected to gas analysis, which is often done to automate or computerize the entire process control depending on the manufacturing conditions. In order to produce a specified class of polymer, certain gas mixtures are required. Concentrations of these gas mixtures must be carefully tracked and if any variations are identified from the ultimate set point, the manufacturer will modify the process variables. This approach allows manufacturers to maintain maximum efficiency in their plants, and at the same time, enables them to protect their equipment from uncontrolled or unusual reactions. Transition events occur on a frequent basis, fast detection of process conditions promotes significant gains in terms of efficiency, and also reduces the quantity of material that needs to be sold as off-specification product. Therefore, the polymer facility depends on precise and fast gas analysis during formula transitions and stable process conditions to achieve the highest efficiency, safety, and product yields.

Real-time Analysis in Polymer Production

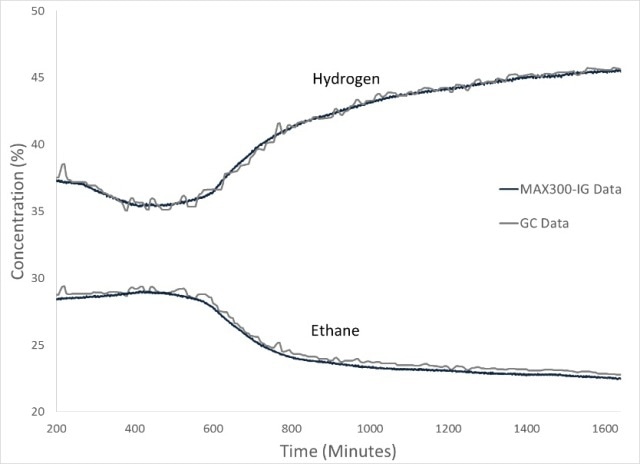

To track the manufacturing operations at a polyethylene facility, the MAX300-IG process gas analyzer was utilized along with a process GC. All the gases present in the process stream were measured by the MAX300-IG, and, ethane, ethylene and hydrogen were determined by the GC. The analysis rate of the MAX300 was 0.4 seconds per component. This allowed the analyzer to measure six streams at the facility at a rate of 10 seconds per stream, with a clearing delay. The fast data acquisition provided a high level of precision and accuracy when compared to the GC data (Figure 1).

Figure 1. The MAX300-IG was used to monitor all components of the polyethylene process. Here, the hydrogen and the ethane trends from the mass spectrometer are shown along with 24 hours of GC data recorded on the same stream.

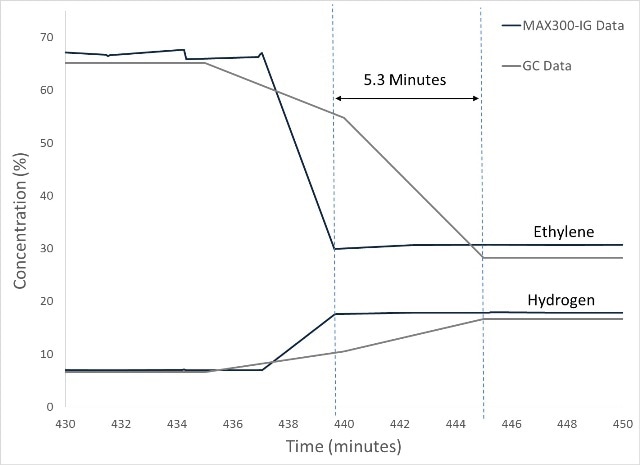

During plant operation, rapid data reporting is very important when one polymeric formulation changes to another formulation. Such changes can take place many times in a single day. The faster this endpoint transition is recognized, the greater the high-value products can be sold. At the test site, the MAX300-IG process gas analyzer detected the endpoint of transition 5.3 minutes sooner than the GC (Figure 2).

Figure 2. During product formula transition, the MAX300-IG identified the endpoint 5.3 minutes faster than the GC analyzing the same sample stream. The ability to quickly identify the onset of production conditions increased the volume of high-value product produced.

Another important factor that needs to be considered is to pinpoint the end of the transition, for instance, if a manufacturing line is yielding 5 tons of low density polyethylene every hour, 5.3 minutes would indicate 0.45 tons of product. During the course of this period, the value of product produced at the same low density polyethylene manufacturing line is $618*. The MAX300-IG process gas analyzer has the required speed to track various manufacturing lines at the same plant. Similarly, at a facility with three manufacturing lines undergoing a transition every couple of days, the value of detecting the end of transition sooner would translate into approximately $29,000 per month.

*At $1,400/metric ton of LDPE

The MAX300-IG

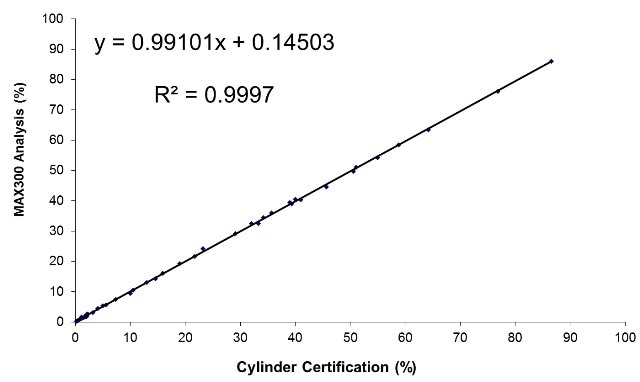

For more than four decades, mass spectrometry has been extensively utilized for industrial process control. When used in polymer applications, the MAX300- IG process gas analyzer (Figure 3) allows real-time measurements of hydrogen, argon, nitrogen, alkane and alkenes in the reactor sample streams, as shown in Table 1. This instrument is designed to determine all components at varying concentrations, spanning from 100% to 10ppb. This dynamic range combined with high linearity is essential during product transitions where concentrations of components can radically change in a short time (Figure 4).

Figure 3. The MAX300-IG, process control mass spectrometer

Table 1. Standard polymer application measurements for the MAX300-IG, process gas analyzer

| Compound |

Analysis m/z |

| NITROGEN |

28 |

| HYDROGEN |

2 |

| METHANE |

16 |

| PROPANE |

29 |

| PROPYLENE |

41 |

| ETHANE |

30 |

| ETHYLENE |

26 |

| 1-BUTENE |

39 |

| OTHER BUTENES |

56 |

| N-BUTANE |

58 |

| ISOBUTANE |

43 |

| PENTANE |

72 |

| 4M1P |

84 |

| 4M2P |

69 |

| 1-HEXENE |

55 |

| N-HEXANE |

86 |

| N-OCTANE |

85 |

| N-DECANE |

142 |

| ARGON |

40 |

The 19mm quadrupole mass filter enables improved sample throughput, long term stability, and high analysis repeatability without experiencing any loss of sensitivity at the high-mass range. The MAX300 analyzer is capable of performing quantitative analysis at a speed of 0.4 seconds per component. Standard maintenance includes changing the pump oil every two years and substituting the plug-and-play ionizer unit. The instrument also eliminates the need for a carrier gas.

Figure 4. The linearity of the MAX300-IG is demonstrated by the analysis of certified gas bottles. This dataset includes readings of propane, propylene, ethane, ethylene and hydrogen. Calibration for instrument response is obtained from a single standard and the analyzer is linear from 100% down to the low detection limit.

Conclusion

The MAX300-IG process gas analyzer is an effective tool for polymer process control. Requiring minimum calibration support and maintenance, the instrument gives both quantitative and real-time measurement of all compounds present in the effluent and inlet streams of various reactors at a production plant. The control system is updated by the analysis rate at 10 seconds for each sample stream. This real-time analysis is integral to sustain highly accurate production control. Additionally, the reactors should be controlled and maintained to optimum conditions in order to maintain equipment with minimum modification, improve product yield, and reduce turnover. During formula transition, endpoint detection is very important. In contrast to the traditional and slower analysis methods, the MAX300-IG provides a cost-effective solution, thanks to its ability to perform fast and accurate gas analysis.

This information has been sourced, reviewed and adapted from materials provided by Process Insights - Mass Spectrometry.

For more information on this source, please visit Process Insights – Mass Spectrometers.