There is a very narrow range of textural characteristics that are associated with bakery products — consumers expect certain things when it comes to the way these products feel and behave when eaten. Any variance from the expected texture is considered a dip in quality.

The difference in the way certain textural properties in bakery products are viewed and the way they are associated with quality are described below:

- Moist cakes and hard biscuits are regarded as quality products.

- Bread is expected to be soft to a certain degree.

- Moist bread is considered stale.

Raw materials and components used in automated bakeries play an important role in manufacturing high-quality bakery products. When these are being sold to distribution networks, storage conditions need to be considered as they can affect shelf-life. The quality of the dough and the raw ingredients used in the bakery can be tested for adherence to industry standards with the help of Mecmesin’s range of fixtures for dough.

The acceptability of bakery products can be tested by emulating the way they are handled, for example, the freshness of bread can be tested by squashing it. It is also important to consider that the coatings or fillings used on baked products may have a considerable effect on the texture of the final product when it reaches the consumer.

Figure 1. Various bakery products and steps of manufacture

Test Methods for the Bakery Sector

The texture of bakery products can be tested with a number of texture testing techniques. These techniques are practical ways of checking the texture based on the way they are handled by the consumer, with tests including breaking, bending, stretching, cutting, and squashing.

Some of the common testing techniques are:

- Deformation assessment of bakery products by subjecting them to shearing, compression, and penetration

- Hardness assessment through breaking tests and bulk analysis

Bulk analysis

Crouton hardness is measured through bulk analysis. A bulk analysis is suitable for when testing a single sample is not feasible, or when it would not represent the way it is handled by the customer. The shearing, compression, and extrusion actions during consumption are replicated by the Kramer Shear Cell (Figure 2). The effect of all these actions is measured together, enabling increased reproducibility of results for a highly variable product.

Figure 2. Measuring Crouton hardness via bulk analysis using Kramer Shear Cell

This method can be used for measuring the crunchiness and freshness of biscuits, and the integrity of the fruit used for filling pies.

Compression

The most appropriate indicator of the freshness of the product is compression, for instance, the way in which a loaf of bread recovers after compression is indicative of its quality. If it retains a good amount of springiness it can be proven to be fresh, whilst crumbliness is a sign of excess loss of moisture. The deformability can be tested through FMBRA compression testing.

Figure 3. FMBRA compression testing

Many textural properties like cohesiveness, springiness, hardness, and fracturability can be assessed by squashing solid and self-supporting samples. This method can also be used for conducting the texture profile analysis of the breadcrumb texture.

Extrusion (back extrusion)

The back extrusion test (Figure 4) can be used for measuring the flow and consistency of the custard. This method is also suitable for testing softer food materials like liquids and pastes that are usually tested inside their packaging. Based on the controlled manner in which semi-solid and viscous liquids are displaced, properties like thinning, consistency, viscosity, spreadability, flow, and adhesiveness can be assessed. The back extrusion method can be used for comparing the composition of different custard formulations, the spreading and yielding properties of fillings and sauces, and the consistency of batter.

Figure 4. Back Extrusion test

Penetration and Puncture

To test the firmness of bread, large size cylinders are pressed into the center (Figure 5), while small balls, cylinders, cones, and needles are penetrated into the surface of the sample to replicate the biting action.

Figure 5. Firmness testing of bread

The changes in the crispness and hardness of bakery products can be tested through penetration and puncture testing, which helps in assessing new formulations, or how different conditions affect shelf-life.

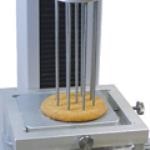

Multiple Point Penetration

This testing method helps evaluate the firmness, maturity and gel strength at multiple points on the same sample since the form and texture may be different in different sections.

Figure 6. Multiple point penetration testing

Shear

Bakery products like croissants need to be subjected to shearing in order to assess their toughness. Cross-sections of croissants are sliced with blades and wires to replicate the action of the front incisor teeth for assessing their tenderness, bite strength, and toughness.

Figure 7. Shear testing of fruit cakes

The sample is subjected to tearing, shearing and compression based on the geometry of the blade, while the texture variations in the sample are evaluated by slicing through it. This method can also be used for evaluating the adhesiveness and consistency of particulates present in fruit cakes. The texture changes due to various processing methods of short dough can be assessed by cutting through it. In order to optimize mixing properties, the cross-sectional hardness of bakery fats and butter can be measured as per ISO 16305.

Snap, Bend, and Break

The fracture characteristics of biscuits can be assessed by using a three-point bend test (Figure 8).

Figure 8. Three-point bend test for biscuits

The fracturability of brittle solids in the form of bars can be tested by this method. The sample is supported at both ends and a force is applied at the center using a knife-edge until it breaks, or until the sample is deformed to a specific point if assessing flexure characteristics.

The degree of softness or freshness of bakery products can be evaluated based on their flexure and fracture properties. However, these properties are desirable only in certain products, while for others, the moisture content is a sign of staleness.

Tension

Tension testing is used to assess the cohesiveness of components present within them (Figure 9). In this test, a ball probe is pressed through a sample to measure its tensile strength.

Figure 9. Tension testing

The freshness of biscuits is indicated by its break resistance and fracture properties. Other properties like extensibility, elasticity, and stretching until break of dough, raw materials, and gluten can be evaluated through tension testing.

In addition to this, the rollability of flour tortillas can be measured by testing the burst strength. The stickiness and adhesion of dough can be evaluated as well.

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.