Dairy products (Figure 1) are manufactured from a complex microstructure of fat and protein and so exhibit a wide range of physical properties. The physical structure, as well as the subjective sensory properties of dairy products, changes significantly from the raw ingredients through manufacturing and post-manufacturing procedures.

Consumers use these sensory properties to assess the quality of a product. Texture measurement, ranging from the spreadability of butter to the firmness of curd is very important in current dairy products, and the same is used by food technologists to evaluate the sensory quality and engineering performance during the manufacturing process.

Figure 1. Dairy products

It is important for manufacturers to ensure that when their products are added to prepared foods, the right consistency is maintained to ensure a high-quality product. In order to change the consumers’ taste to a new product, healthier versions must have a mouthfeel similar to their counterparts. The following descriptions are used by consumers to gauge their perceptions:

- Softness

- Creaminess

- Thickness

- Chewiness

- Stickiness

Sensory terms cannot be easily converted into basic functional and physical properties. In order to correlate the sensory terms, several test techniques may need to be applied.

Test Methods for the Dairy Sector

There are certain texture testing methods that can be used to determine the texture of dairy products. It is key to ensure that texture testing is kept both real and practical by utilizing methods that optimally replicate product handling by consumers, for instance, spreading, pouring, bending, squashing, and cutting the product.

Some examples of dairy texture measurement include testing viscous liquids (i.e. yogurt) to assess spoonability and flowability, and determining shredability of cheese for better control in production and softening.

Bulk Analysis

Bulk analysis (Figure 2) is used for assessing the firmness of curd, and bulk shearing is used for determining cottage cheese curd at different formulations of PH value.

Figure 2. Dairy bulk analysis

Compression

When self-supporting and solid samples are squashed, different textural properties can be assessed, such as springiness, hardness, fracturability, and stickiness. Compression testing (Figure 3) can be used for evaluating the crumbliness of feta cheese, determining the springiness and elasticity of soft cheeses such as brie, and assessing the compression behavior of hard cheeses like cheddar.

Figure 3. Dairy compression test

Extrusion (Back Extrusion)

Extrusion tests (Figure 4) can be applied to liquids, pastes, and other softer foods. These products can be tested in their own packaging without actually removing them. In this test, semi-solid liquids and viscous liquids are displaced in a controlled way to examine several properties such as viscosity, consistency, thickening, thinning, spreadability, adhesiveness, and flow. For dairy products like creams and yogurt, the extrusion test will detect flow properties and spoonability of the end product. Applications of the extrusion test include:

- Shear-thinning in pumps of soured cream

- Flow properties of fromage frais

- Extrusion comparison between full fat and low-fat yogurts

Figure 4. Dairy extrusion test

Penetration and Puncture

A ball probe is employed to measure the consistency of dips. Tools like balls, small cylinders, cones, and needles are used to pierce the surface of a sample in a way that mimics biting or chewing in the mouth. Penetration and puncture test (Figure 5) is used for:

- Determining the body and consistency of gelled structure

- Pressing on camembert surface to evaluate ripeness

- Assessing the thickening of mousse

Figure 5. Penetration and puncture test of a dairy product

Multiple Point Penetration

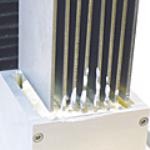

Multiple point analysis (Figure 6) can be used for measuring the firmness of cheese containing particulates. It is utilized to test various points on a single sample, whose form and texture can differ largely from area to area to determine properties like maturity, gel strength, and firmness.

This can comprise multiple-layered products or particulates like cheese in which texture varies from one point to the next point. Firmness-enabling particulates in fruited cheese are one application of multiple point analysis.

Figure 6. Multiple point penetration test of a dairy product

Shear

In shear testing (Figure 7), wires and blades are used to slice samples, and their cross-sections can then be studied in detail. These wires and blades mimic the action applied by incisor teeth. Properties such as toughness, tenderness, and bite strength are evaluated. The difference in product texture is quantified by slicing through the entire sample. When considering the viability of products like cheese for machining purposes, this test provides an indicator of shredability.

Figure 7. Shear test on a dairy product

Shear testing can be used to determine the firmness of butter in accordance with ISO standard 16305, and also to assess the fracture characteristics of hard cheese to judge its slicing or grating hardness.

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.