Consumer acceptance of food products relies heavily on their texture and mouthfeel. At times, texture characteristics are even more important than the appearance, taste or smell.

The way in which the brain interprets the physical characteristics of the food while chewing is the property meant by texture. The mouthfeel refers to the interaction between the food and the surfaces in the mouth, and the way this feels for the consumer.

Some of the different terms used to describe food texture are soft, hard, crispy, or crunchy. Terms like fresh, stale, and ripe are also used to describe food products.

Based on the mouthfeel alone, one cannot establish a consumer’s sensory relationship with food — this starts long before mouth feel, and certainly before the taste test. Some other important things to be considered are the way it feels while handling the product, whether being mixed or pressed during preparation, tapped or squeezed at the sale point, or grasped or torn when being lifted up to the mouth.

Finger feel is the texture-based interaction that is related to the sense of touch. Texture also influences the way the product and its ingredients interact with the production equipment.

Different actions like extrusion, slicing, or compression is performed from when the product is being made from its raw ingredients through to when it is served to bear an influence on the consumer's interpretation of the product.

Making sense of sensory

The basis of texture analysis stems from the fact that there is a clear benefit from understanding the way in which the sensory experience for the end customer can be optimized.

Based on customer feedback obtained from surveys and evaluation panels, processors determine the expected texture of a product. These characteristics can be measured and controlled using a scientifically developed test method that is based on the information gathered. The measured test data is correlated with ideal products using a texture analyzer.

The interaction between the consumer and the product is mimicked to create an accurate and relevant test. As the consumer often bases their decision on a product's texture, the food sample must be deformed in the same way that the consumer will experience. Replicating the preparation and presentation of the test sample is vital to derive accurate results.

The Kramer shear cell from Mecmesin can be used to test bulk samples of food products by replicating the motion of chewing or biting to determine tenderness or firmness data (Figure 1).

Maintaining standards

Comprehensive knowledge of the measurable parameters that influence the quality, and the capability to test them, enables the manufacturer to react to external influences and trends.

The variability in the raw ingredient supply and revisions in regulations related to nutrition, the environment, and safety need to be kept in mind. Over the years, a number of standard tests have evolved in the industry, with the aims of standardizing the textural quality of raw ingredients, assessing the produce at the point of harvest, and classifying products at the initial stages of the supply chain.

These tests, and the special fixtures used for performing them, were designed by pioneers who acknowledged the need for quantifying the grading of food. The Bloom strength testing of gelatin, which generates a hardness value as a result of the compressive force on a gel of known concentration, is one such example.

Some examples of fixtures used in these tests include the Magness-Taylor probes for testing the ripeness of fresh fruit through penetration and blades used to shear meat for measuring tenderness during the packing and processing stages (Figure 2).

An example of food products that are influenced by safety regulations are canned and retorted products. These products are preserved by thermal processing, which can influence their final texture.

Generally, the firmness of products that are subjected to hotter conditions, or longer cook times for sterilization, is reduced, which tends to reduce consumer acceptance. However, that the product is sterilized is more important than its texture profile is. After thermal processing, sensory and instrumental texture analysis may be conducted to determine the significance of the change in texture.

This kind of product is considered fit for release if the texture is within the criteria derived from initial testing. If it is not within the criteria, the processors work towards making necessary alterations in the formulation in order to make it fit. One commonly used method for modifying the texture is the addition of calcium, which helps maintain the required texture and mouthfeel. Such alterations are first tested on a small scale before being applied to large-scale production.

At times, the desired texture for the consumer may be easy to achieve in production, but this is not always the case. A dairy product that is rich and creamy flows consistently, holds its shape well, and feels firm to touch, may not be easily delivered from filler-line nozzles.

The use of a texture analyzer allows the food manufacturing industry to exercise control over their production processes. The settings of food processing equipment are influenced by the physical properties of the product.

Another factor that influences customer acceptance is the choice of packaging, which may affect the texture of the product, resulting in a change to the mouthfeel.

Tolerance and conflict resolution

The taste and preference of the end-customer change frequently, with some of the currently popular taste preferences including sugar-free, fat-free, dairy-free, GMO-free, gluten-free, additive-free and preservative-free. Producing a product that meets these demands may result in a compromise of the final texture of the product.

A common perception is that fat content influences the relationship between the quality and the texture of the product. This is because the mouth feel of fatty food products is associated with richness, higher quality, and better transmission of taste, because of the structure of fats. Texture analysis can be used to compare the texture of low-fat alternatives with traditional product formulations.

The thickness and consistency of semi-solid dairy products like dips, yogurts, and sauces can be tested and compared with baseline data obtained from extrusion methods. The quality perception of such products depends on the way they are served, mostly by spooning or pouring from containers. The flexible range of accessories available from Mecmesin allows the producer to use the back extrusion method to closely replicate consumer interaction with the product in its own packaging.

In the back extrusion method, a probe in the form of a cylinder, or a flat or circular plate, is lowered like a plunger into the sample, which is confined within a cylindrical receptacle. The product is extruded back between the plunger and the cylinder to measure the force. The overall firmness of the sample is given by the peak force. The energy needed to initiate and maintain the flow is provided by the area under a force vs displacement graph.

The behavior of a sample may be assessed multiple times during the important elements of its processing. The forward extrusion method is used to replicate the flow through the filling machine, where it is forced to flow through a hole of known diameter at the bottom of the cylinder containing it. This hole represents the nozzle bore.

In order to ensure maximum forward extrusion, the tolerance between the cylinder fixture and the plunger must be close. The manufacturer can gain considerable information for profiling the behavior of the sample by varying the hole diameter and cylinder clearance (Figure 3).

Fresh processed meats and vegetarian substitutes may also be examined based on similar texture analysis, with an equivalent texture preferred by the consumer. This information can be used for optimizing forming and pressing equipment.

The Complete Package

The taste, smell, appearance, and texture of the food product is protected by its local environment once it enters the packaging stage.

Packaging is required to protect this environment in accordance with environmental regulations and consumer opinion. The two main consumer acceptance criteria that rely on the effectiveness of packaging are the need for crisp and crumbly food items to be delivered in a non-crumbled state, and the need for a useful shelf life of bakery products.

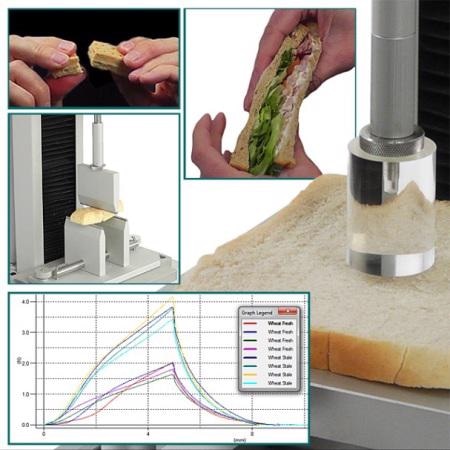

In bread staling tests (Figure 41), the product is squeezed by applying a compressive force, where a lower peak force for a specific displacement indicates the softness and freshness of the item. Stale items, which harden over time, have an increased peak force. Measurement can help to find alternate packaging options.

The assessment of brittle foods is based on their break resistance, wherein if the food breaks all at once, the product is of good quality. The break resistance also provides data that helps minimize damage during transportation. Using the 3-point bend fixture, one can assess the shelf life qualities of bakery products by plotting the reduction in force needed for breaking.

Figure 1. Bread staling and biscuit snap strength tests evaluate packaging performance in addition to consumer acceptance criteria

Money where the Mouth is

The ultimate aim is to deliver a product on time and safely to the customer in an undamaged state. Apart from ensuring the safety of the product, it is also important to maintain its quality in order to avoid complaints from the consumer end. Measurement techniques like sensory testing and texture analysis, and control of the formulation and processing parameters, enable companies to meet customer expectations.

Although taste is the main factor in gaining customer acceptance, it is a subjective assessment in which likes are subjective. Therefore, a more quantifiable assessment can be made by evaluating the mechanical properties that determine the physical texture. Attributes like crispiness, ripeness or tenderness can be quantitatively determined with the help of a texture analyzer. Producers have to decide on objectively quantifiable attributes so that their unique selling point is maintained. Taste comes much later in the consumer acceptance cycle, for which texture is the first important step.

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.