Interview conducted by Mychealla RiceAug 16 2016

Interview conducted by Mychealla RiceAug 16 2016

Mike DiGiacomo, Sales Engineer from Paratherm, talks to AZoM about the benefits of Paratherm’s heat transfer fluids and how they differ from traditional fluids.

Can you give a brief background about Paratherm and the work you do?

I have been with Paratherm for 3 years and am the Western US and Canada sales engineer for general industry. This includes Asphalt, Chemical Processing, Converting, Laundry, Liquid Terminals, Plastics and other smaller niche markets. I assist heat transfer users select the correct fluid for their application and troubleshoot problems that they are having with their systems.

Please can you tell us about Paratherm’s different Heat transfer fluids?

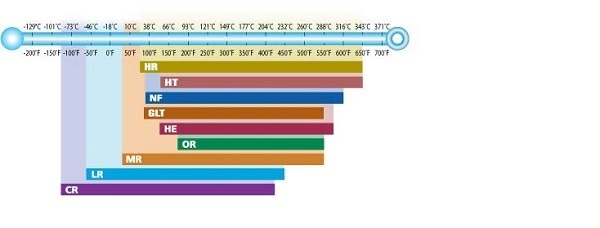

Paratherm’s heat transfer fluids are specifically engineered for temperature ranges and applications. We balance factors such as base chemistry, physical properties (density, viscosity, thermal conductivity), level of refinement (purity), and proprietary formulation to make the highest quality heat transfer fluids available. We offer 9 different heat transfer fluids, 3 system cleaners, and an oxidation inhibitor additive. Our fluid chemistries include natural organic hydrocarbons and also high temperature synthetic hydrocarbons.

How do Paratherm’s heat transfer fluids compare to other traditional fluids? What are the differences?

Paratherm’s heat transfer fluid line offers fluids that range in temperature from -127°F all the way to 675°F. We have a fluid that will not only meet but exceed most customers’ needs. Our fluids are compatible with most of our competitor’s fluids but our engineering R&D has allowed us to create more thermally stable fluids at higher temperatures that result in our fluids lasting longer under the same operating conditions as our competition.

How does Paratherm’s heat transfer fluids compare to lower-cost alternatives such as water and steam?

Water and steam definitely have their place in the heat transfer fluid world because most plants have a steam based system. With that being said there are some limitations and safety concerns with operating steam at high temperatures (under extreme pressure). In some states like California a full time steam operator is required at all times. For systems running Paratherm fluids, the beauty is the fluids run at a much lower pressure (less than 1 atm) and do not require a full time operator.

Oxidation and fouling are common problems with heat transfer fluids. How do Paratherm’s solutions detect and resolve issues like these?

Oxidation is the most common problem for oil based heat transfer fluids. Other fouling issues like increased high and low boilers of are concern too. Paratherm recommends at least yearly testing of the fluid. We test for the Total Acid number (TAN) as a check on oxidation issues, we test for viscosity and run a distillation of the sample to check for low and high boilers. We review each test with the customer, in comparison with the specific fluid baseline data, and will make recommendations based on our findings. This can include site visits and a review of the system design to help the customer get the longest life possible out of our fluids.

Which heat transfer fluid would you recommend for temperature control? Why?

There are many factors that go into selecting a fluid. First we need to understand the customer’s temperature needs, are they heating, cooling or both and is a dual purpose fluid needed for heating and cooling. We also have a look at the heating method itself: gas fired heater, electric heater, waste heat. Different heat sources carry varied thermal impact, at a molecular level, upon the fluid base. Will this installation be indoors or outdoors and is there a need for a low temperature start up? Will there be frequent start-ups and shutdowns? Is it a batch or a continuous process? Will frequent system component exchanges introduce oxidation liabilities?

Economics can also factor into the selection of a fluid and many times a customer will think they need a high-temperature synthetic even though they will never run near the maximum operating temperature limit. Can they run a high temp synthetic at a much lower temperature? Sure but there are many other options available and they don’t need to spend the extra money to do so.

How important is regular fluid analysis and maintaining your thermal oil system?

It can be compared to a blood test for medical diagnosis. Regular fluid analysis is very important to maintaining the thermal oil system. Many times we can catch something wrong with the system and see it in the fluid test results before a larger problem happens. We track year-on year change in the fluid and can make recommendations to the system based on our findings. to extend the life of the fluid.

What industries will benefit from using Paratherm’s heat transfer fluid? What will it mean for them in the long term?

Asphalt Paving, Chemical Processing, Engineered Wood, Gas Processing, Industrial Laundry, Plastics, and Poultry and Meat. Our customers know that in the long term they will benefit from using Paratherm because we are the most service oriented supplier in the industry. Our mission is to keep our customers applications up and running while maintaining and extending the life of their equipment. We have warehouses throughout the US and world to ensure quick delivery. We also offer emergency shipments around the clock when needed.

Where can our readers go to find out more?

Our newly redesigned website has a wealth of knowledge geared towards hot oil systems and maintenance. www.paratherm.com

About Mike DiGiacomo

Mike DiGiacomo is a Sales Engineer at Paratherm. Mike has over 10 years of experience in technical and industrial sales sector.

Mike graduated from the University of Delaware specialising in Biological Sciences.

This information has been sourced, reviewed and adapted from materials provided by Paratherm.

For more information on this source, please visit Paratherm.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.