Extrusion testing has several applications within the food and other industries, for texture assessment. This method is suitable for viscous liquids or semi-solids, where the product’s rheological properties affect the flow.

Forward extrusion and back extrusion are two categories of extrusion testing. In forward extrusion, the test sample is placed into a confined container and then forced through a grid or an orifice. The foods’ resistance to this extrusion is then measured. The size of the grid or orifice selected is based on the textural property of interest and the product being measured.

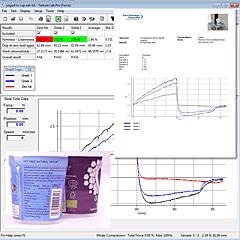

Typically, back extrusion is carried out by placing the product to be measured in an open-top cylinder. This is followed by forcing down a piston with a diameter smaller than the cylinder into the sample. The outcome is that the product flows back between the space created by the cylinder and the piston.

Test Procedures

For example, sour cream becomes grainy when it is not processed properly. Forcing sour cream through a small orifice using forward extrusion, will result in a smooth force level or a jagged one. The jagged one occurs when the grains alternately become plugged and unplugged in the orifice building and then release backpressure.

Back extrusion is a more commonly used method of extrusion testing. The gap between the cylinder and the piston is a key factor to be considered in back extrusion. This is known as the annulus - the smaller the annulus, the greater the resistance to the flow.

To achieve consistency in the testing of viscous liquids, once decanted, samples should be allowed to recover structure in a controlled environment.

Extrusion testing fixtures

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.