There are some differences between the quality acceptance of pet food/animal feed and that of food products produced for human consumption. Particularly in the pet industry, the texture must appeal to both the owner/consumer and the animal consuming the food.

Food palatability in terms of smell, taste, appearance¸ and texture should ensure that the animal eats the product, and these attributes should also be able to satisfy human sensory processing, with the possible exception of taste.

All food meant for animal consumption has required safety and nutritional targets, which limit the variability possible during the formulation process. Therefore, after establishing the acceptability criteria, it is advantageous to use texture analysis techniques to determine the measurable properties.

As with any food product intended for human consumption, the correlation to desirable texture first involves sensory testing different samples. The difficulty for animal food products is obtaining feedback from the subjects, which are known to have heightened senses compared to humans. Often, a product that is not rejected is considered desirable, although it is possible to design experiments to rate preference of one formulation over another.

Cats (carnivores) and dogs (omnivores) represent the majority of the pet food market. Treat items, products for daily consumption, and occasional veterinary prescribed medication are the food categories that owners would need to provide to their pets, with the option of dry or wet formulation.

Variability of Ingredients and Processing

The final animal food texture is influenced by several factors including the manufacturing process, the selection of raw ingredients, and the need to dispense the product to its packaging in the most efficient and economical way.

A nutritionist drives the ingredient mix, specifying limits for proteins, carbohydrates, amino acids, minerals, and vitamins, amongst other things. This ensures a variety of diet as well as a balance of the essential needs of the animal’s biology such as meat, vegetable content, etc.

In addition, there are specific formulations that can be used to enhance conditioning or provide more medical support for pet animals, including:

- Puppy /kitten (young), adult, and senior life stages

- Urinary tract maintenance, dental hygiene, hairball control, and joint health

- Reduced calorie for inactive, obese, or indoor pets

Kibble-like products such as nuggets and pellets that are fed to small mammals and rodents are subject to the same processing challenges. When ingredients are processed to form the end product, additional elements are introduced that can negatively affect the texture.

It is important to optimize the operational parameters of the manufacturing equipment to maintain the operational efficiency, but the resulting product is still palatable.

Heat treatment or thermal processing is applied to animal food to ensure safety, shelf life performance, and stability, but it impacts animal fats and proteins, which are essential to the nutrition and palatability. The production throughput of extruded, shaped dry kibble pellets and viscous, wet food, supplied via filling machines, is susceptible to the physical properties of the ingredients at the production stage and, must be balanced against the end texture.

These consumer choices extend the variability in raw materials, possibly introducing uncertainty to the production of desired texture and increasing the need to quantitatively define it via texture analysis. Similarly, the parameters controlling dispensing of a product into its packaging, whether pouch, can, sachet, tray or retort, can be evaluated for their impact.

Animal Feed

Like pet foods, nutrition and safety regulations also apply to food products for animal husbandry, which are a sub-category of animal feed. The regulations are concerned with the fact that farm animals are part of the human food chain.

The nutritional requirements are considered towards commercially optimal meat and dairy produce, instead of extended lifespan. The same challenges exist in balancing the production, packaging, storage, and transportation of the feed, with the required palatability.

Test Methods for the Pet Food Sector

In the animal feed industry, texture measurement can help to maintain the consistency of palatable products, regardless of changing ingredients or the improvement of shelf life or packaging options. It is possible to test biscuits, pellets, dry kibble, packaged or canned wet foods in the same manner as similar consumer products.

Bulk Analysis

Determining tiny particulates in confections, such as meringue, is more accurate in bulk form.

- Compare dry, extruded, or baked food processing

- Quality of animal feed

- Overall bulk hardness and firmness of pet food

Penetration and Puncture

- Hardness, bite force of pressed/rawhide bone

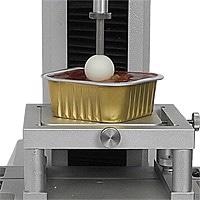

- Firmness testing wet food

Multiple Point Penetration

- Firmness testing (in the tray, tin, can), chunks in jelly, wet food

Shear

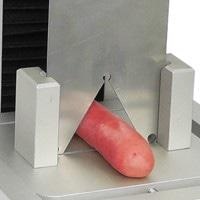

Cross-sections of samples can be measured by slicing through them with wires and blades that mimic the actions applied by the front incisor teeth. Attributes such as toughness, tenderness, bite strength, and cook quality are assessed. Variations in product texture are determined by slicing through the entire sample.

- Measure the hardness of flavor enhancement coatings

- Bite force, shear, and cutting resistance of meaty treats

Snap, Bend, and Break

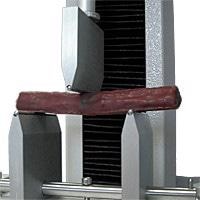

The three-point bend is suitable for measuring the brittleness or flexibility of bar-shaped treats.

- Dog biscuit/cookie snap strength

- Chew treat flexibility, bend strength

Tension

- Tensile strength, and elasticity of chewy treat

Gelatin Testing

Gelatin (gelatine), a natural protein of animal origin, is widely used in many pet foods. It performs various functions, any of which may be the main purpose.

- Protein fortification for nutritional benefit

- Elasticity to provide the desired level of chewiness and softness

- Safety and health improvement, easily digested, and low calorie

- Kibble quality and stability, unaffected by extrusion

Testing the gelatin’s bloom strength in-house provides control over the formulation process.

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.