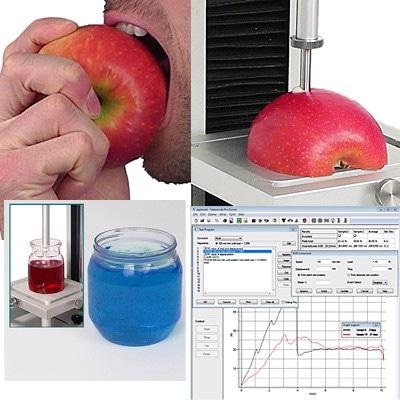

Texture and the associated mouthfeel of a food item, or finger feel of a product where sensory perception is fundamental (e.g. nutraceuticals, cosmetics) has an important role to play in the consumer's evaluation and acceptance of that product. These characteristics play a more significant role in some cases than those of appearance, smell, or taste.

If the producer can understand how the consumer views the texture, it is possible to conduct scientific measurements and analyses that can deliver consistent quality aligned to desirable properties.

Consumer evaluation panels often perform the initial evaluation, which is important to obtain a better understanding of preferences and terminologies. After obtaining this information, the producer can correlate their own internal expertise and data to the sensory findings.

A product can be accurately and repeatedly tested using a texture analyzer to measure numerical output against the subjective findings. The impact of changes to ingredients or preparation can be scientifically quantified and measures are taken to match or improve previous formulations, or a competitor's offering.

Texture Analysis in R&D and Academia

Texture measurement systems from Mecmesin are used in Schools, colleges, and universities worldwide.

A practical texture analysis capability is useful in science disciplines with a focus on laboratory work and the physical analysis of pharmaceutical or food products. The physical properties of samples can then be tested by academic departments in food science and nutrition, or chemistry, which cover food technology and food/nutraceutical/pharmaceutical product design and development.

These facilities can also be utilized by related courses that cover food safety and strategy, environmental sustainability, the agri-food business, economics, and marketing to appreciate the balance with processing, production, and shelf-life requirements.

Research programs addressing the challenges in combating the impact of poor harvests, delivering nutrition, optimizing various elements of the food supply chains, and studying digestive health issues are some project areas where instruments such as texture analyzers may be used.

A measured scientific approach is essential to completely understand the complexity of the structure of food products that leads to complex behavior when undergoing deformation.

The textures derived from mechanical properties range from brittle fracture to viscoelastic flow, and the variety of Mecmesin fixtures designed to recreate the interaction of a consumer - or processing and packing equipment - with the sample enables relevant testing and detailed correlation studies.

In industry, R&D facilities can apply a scientific approach for product improvement, while achieving consistent quality and minimizing costs. Cosmetics, pharmaceutical, and food companies can achieve a controlled texture, to maintain a competitive advantage, regardless of a changing business and legislative environment.

With Emperor software, the MultiTest-i system enables the development of custom test procedures to conduct thorough and complex research experiments. (The MultiTest-i has been superseded by the OmniTest universal testing machine)

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.