The Department of Bioengineering at Imperial College London was a pioneering institute in the formulation of this field and today is the leading facility of its kind in the United Kingdom. In close collaboration with industry partnerships, the department develops innovative technologies, with both undergraduate and postgraduate degree courses and diverse research activities.

The specialized nature of this field poses unique challenges, through its cross-disciplinary activities in pure engineering, clinical practice, and biomedical sciences. Experience of the practical aspects of this emerging field is an essential foundation for students graduating from this world-renowned institution.

The department required testing equipment for its own laboratory for training in solid mechanics as well as for use with pre-existing, custom-made testing rigs.

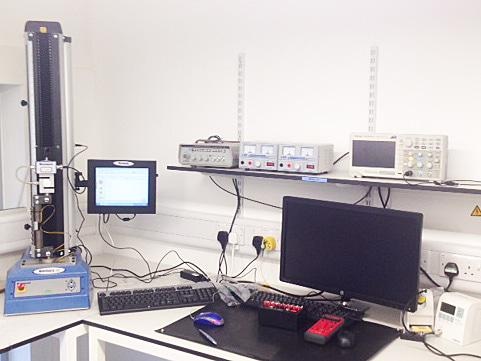

The MultiTest has a small footprint and is easily housed in the Bioengineering laboratory

The Solution

Mecmesin provided a touch screen controlled UTM with fixtures and a 5 kN loadcell, rated to accomodate the expected force values in the range of tests on mild steel specimens. The touch screen operation was suited for the educational setting, where specific test procedures are programmed and then run by choosing an icon.

The focus is on gaining insight from the test results rather than the programming. Fortunately, only minimal training is required to operate the MultiTest xt, though controlled by powerful Emperor™ software. It is possible to add new programs to the library when required, offering the flexibility to adapt to an expanding curriculum.

Bone repair plate: strain-gauges record compression and flexure deformation data

The system enables results and calculations to be displayed immediately alongside the graph, indicating the key features of the load-displacement curve. The data is used as output for subsequent calculation and comparison of the mechanical properties of the test samples, including yield stress, ultimate tensile strength, and Young’s Modulus.

In the tensile tests, repeatable and controllable deformation behavior is exhibited by dog-bone specimens, demonstrating the fundamental engineering theory.

The versatile test stand can perform compression procedures relevant to the real world applications of biomechanical components, such as broken bones and prosthetics, where compression and bending forces are experienced, or an intricate physical design with cut-outs or holes to induce stress concentrations.

Using strain gauges, the department collects data for material property calculations for a complete analysis capability.

The System

- MultiTest 5-xt touch screen controlled test stand (Superseded by the OmniTest Touch 5 universal testing machine

- Wedge grips and adapters

- 5 kN intelligent S-beam loadcell

- Imperial College London's own custom-made testing rigs

Testimonial

The Bioengineering Department at Imperial required a new system for teaching purposes to demonstrate tensile and compressive testing on a range of different materials and custom fixtures. A system was needed that was flexible and easy to use but with a compact form that would fit our available space. The MultiTest 5-xt was an ideal solution and the hardware support from Mecmesin has been excellent.

Dr. Dominic Southgate, Senior Teaching Fellow, School of Design Engineering

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.