For testing, gripping a sample correctly is an essential aspect of test repeatability.

It is necessary to firmly hold the sample to avoid slippage, but without distorting it or introducing localized changes in the performance of the sample under load.

Suitable fixtures bring together the following features:

- Interchangeability

- Adjustment for alignment

- The method of tightening

- Size capacity

- The surface of the grip faces

- Characteristics for loading: axial force or torque

Testing to Industry Standards

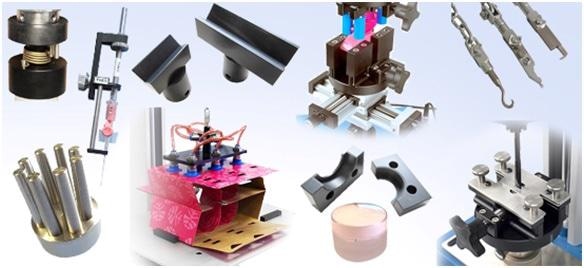

Industry standard methods often specify the gripping method. Mecmesin can provide a full range of approved grips and fixtures for use with all of its instruments and systems.

The company’s accessories catalog consists of everything required for a complete testing solution, including grips and cradles, cables and peripherals, and load and torque cells and sensors.

Download the Materials Testing eBook

Download the Materials Testing eBook

Custom Grips for Unique Applications

Custom grips are often needed to test flexible, molded or asymmetric items. Mecmesin has an expert in-house design and manufacturing facility to address these specific requirements.

These typically include fixtures for torsion springs, containment and guards, jigs for bending awkward or large items, grips for control devices with moving parts, cap mandrels to fit specific designs, vacuum fixtures for preform packaging, and much more.

Custom-engineered Solutions for Force & Torque Measurement - Mecmesin

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.