This article discusses the three-dimensional electron backscattered diffraction (3D EBSD) analysis of a microstructure of Ti-6Al-4V (Ti64) alloy produced by direct metal deposition using a focused ion beam scanning electron microscope (FIB-SEM). In this example, data was acquired using an innovative static position 3D EBSD configuration.

The new methods used for net shape fabrication are cheaper alternatives to the traditional Ti alloy preparation techniques involving casting and machining (see e.g.1). An approach similar to that of 3D printing is employed to fabricate components from powder or rod substrates, eliminating the machining process.

An electron beam free-form fabrication or a shaped metal deposition are examples of the fabrication possibilities for low-quantity production of intricately shaped components (Figure 1). However, the microstructure and therefore, the mechanical properties may vary. Specifically, the anisotropy and porosity need to be carefully analyzed, as demonstrated in3.

The 3D EBSD analysis for precise description of the phase distribution, microstructure, and grain formation in materials following annealing was introduced in4.

![Honeycomb-like structure with controlled porosity for biomedical applications, prepared by a direct metal deposition of Ti64. [2]](https://www.azom.com/images/Article_Images/ImageForArticle_13545_45415122362141219793.jpg)

Figure 1. Honeycomb-like structure with controlled porosity for biomedical applications, prepared by a direct metal deposition of Ti642.

3D EBSD

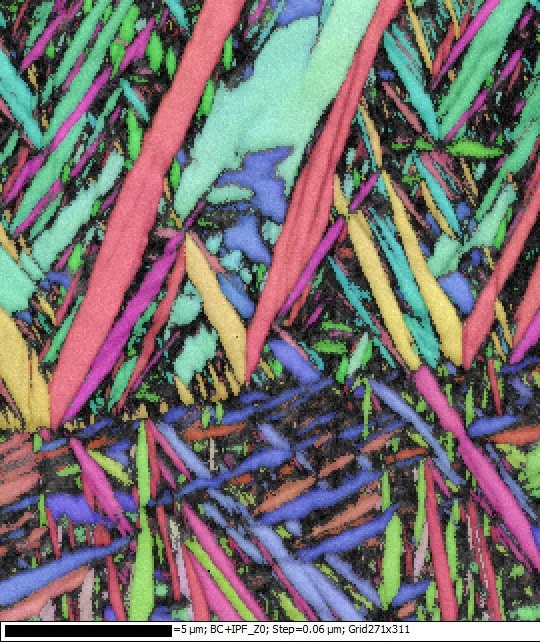

One examples of FIB-SEM tomography is 3D EBSD, which involves serial FIB cross-sectioning followed by orientation mapping by EBSD (2D) to obtain a 3D orientation dataset of the selected volume. Figure 2 shows an example of a 2D EBSD map of a cross-section.

The traditional method for 3D EBSD data acquisition uses sample movement between the EBSD acquisition position and the FIB milling. However, this technique has many serious disadvantages relating to the precision and speed of data acquisition5.

TESCAN FIB-SEM provides a static setup for the 3D EBSD analysis based on a special EBSD camera configuration developed as part of the FIBLYS project6. This configuration facilitates performing EBSD acquisition and FIB milling simultaneously in a static sample position.

Figure 2. 2D EBSD orientation map of the Ti64 microstructure.

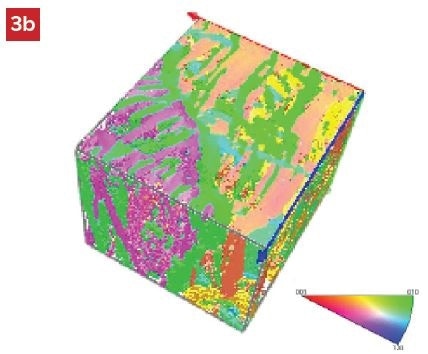

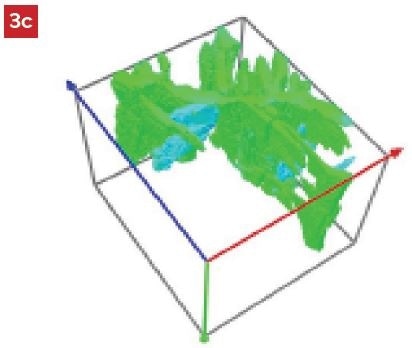

Figure 3. 3D EBSD visualization after post processing in a) Euler angles as RGB color, b) inverse pole figure (IPF-Z) with color legend, c) visualization of a single grain after grain segmentation using mis-orientation limit > 2 deg.

Static 3D EBSD Method

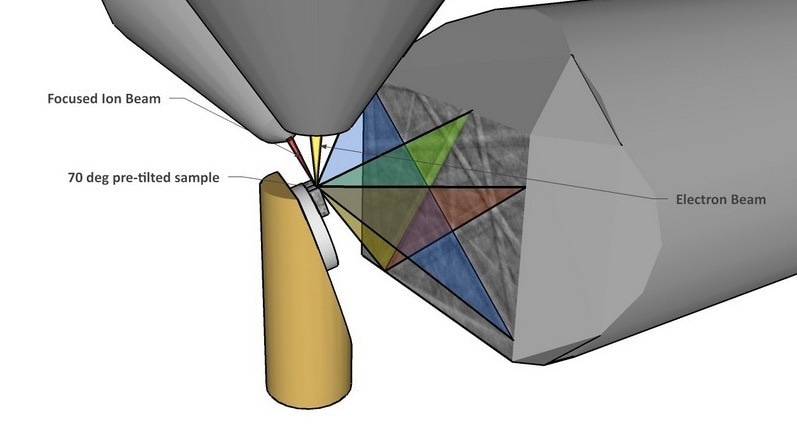

The core concept of the “static 3D EBSD” method was put forward and first realized as part of the FIBLYS project5. This static configuration allows 3D EBSD acquisition without having to move the sample during the whole data acquisition process. Figure 4 schematically shows the configuration.

Figure 4. Static position 3D EBSD configuration on TESCAN FIB-SEM

The static configuration is advantageous over conventional movable 3D EBSD setups in many ways:

- Easy process setup

- Highest possible acquisition speed

- Highest possible EBSD resolution

- The EBSD camera can be placed very close to the sample without any risk of screen damage during the sample movement

- Highest possible acquisition accuracy

- Eliminating correction for stage inaccuracies (rotation, tilt, shift)

Experiment and Results

The acquisition was performed using a LYRA3 FIB-SEM featuring Oxford Instruments EBSD NordlysNano. Oxford Instruments 3D Viewer was used to perform the post-processing and visualization of the 3D EBSD dataset acquired.

Acknowledgments

This experiment was carried out in cooperation between TESCAN and Oxford Instruments application laboratories.

References and Further Reading

- G.P. Dinda, L. Song, and J. Mazumder, Fabrication of Ti-6Al-4V Scaffolds by Direct Metal Deposition, Met-allurgical and Materials Transactions A, vol. 39A,Springer 2008, pp. 2914-2922,

- Xiang Li, Chengtao Wang, Wenguang Zhang, Yuanchao Li, (2010) “Fabrication and compressive properties of Ti6Al4V implant with honeycomb-like structure for biomedical applications”, Rapid Prototyping Journal, Vol. 16 Iss: 1, pp.44 - 49

- B. Baufeld and O. Biest, “Mechanical properties of Ti-6Al-4V specimens produced by shaped metal deposi-tion”, Sci. Technol. Adv. Mater. 10 (2009)

- R. E. A. Williams, M. Uchic, D. Dimiduk and H. L. Fraser (2005). Three-Dimensional Reconstruction of Alpha Laths in Alpha/beta Titanium Alloys …, Microscopy and Microanalysis, 11 (Suppl. 02) , pp. 836-837.

- S. Zaefferer, “3-Dimensional Orientation microscopy Using FIB-EBSD Tomography: An overview on Tech-niques, Applications and limits”, Book of abstracts pp. 123-136, EMAS Workshop 2009

- Description of a new 3D EBSD method without the additional sample movement, FIBLYS - Building an An-alyzing Focused Ion Beam (FIB) for Nanotechnology, 2009,

TESCAN Group

Founded in 1991 by a group of managers and engineers from Tesla with its electron microscopy history starting in the 1950’s, today TESCAN is a globally renowned supplier of Focused Ion Beam workstations, Scanning Electron Microscopes and Optical Microscopes. TESCAN’s innovative solutions and collaborative nature with its customers have won it a leading position in the world of nano- and microtechnology. The company is proud to participate in premier research projects with prominent institutions across a range of scientific fields. TESCAN provides its clients with leading-class products in terms of value, quality and reliability. TESCAN Group is the North American arm of TESCAN Group, a multinational company established by the merger of Czech company TESCAN, a leading global supplier of SEMs and Focused Ion Beam workstations, and the French company ORSAY PHYSICS, a world leader in customized Focused Ion Beam and Electron Beam technology.

This information has been sourced, reviewed and adapted from materials provided by TESCAN Group.

For more information on this source, please visit TESCAN Group.