Introduction

Fused silica is an amorphous material, characterised by its extremely low co-efficient of thermal expansion and resistance to thermal shock.

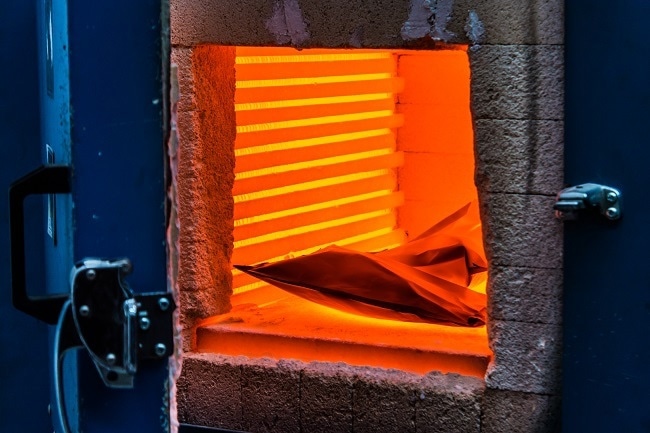

Fused silica is produced by melting high purity silica at extremely high temperatures in an electric arc furnace or resistance furnace. It can be solidified and annealed without crystallising due to its extremely high viscosity.

However, it will devitrify at temperatures over 1100 °C.

Optical and general purpose rods are drawn from the melt.

Key Properties

- Lowest co-efficient of thermal expansion of any known material.

- High resistance to thermal shock

- Low thermal conductivity

- Excellent electrical insulation up to approximately 1000 °C

- Excellent resistance to corrosion from molten metals and glass

- Low dielectric constant

- Low dielectric loss

- Good UV transparency

- Easily machined to tight tolerances

- Dissolves in hydrofluoric acid (HF)

Applications

- Refractories

- Investment casting

- A filler in electronic encapsulation materials

- Specialty coatings

- Optical windows suitable for elevated temperatures

- Microwave and millimetre wave components

- Radar windows

Fused silica is produced at extrmely high tempertatures is used in applications such as refractories which are used in furnaces. Image Credit: Shutterstock/SitthichaiSuntuang

Primary author: AZoM.com