Induction brazing along with pre-laid brazing foil ensures absolutely uniform connections. This is why the technique has been frequently used for demanding output leads on transformers. A precise working temperature for brazing is supplied by eldec’s MICO-L 50 MF in a reliable manner.

Solid Brazed Connection with Brazing Foil

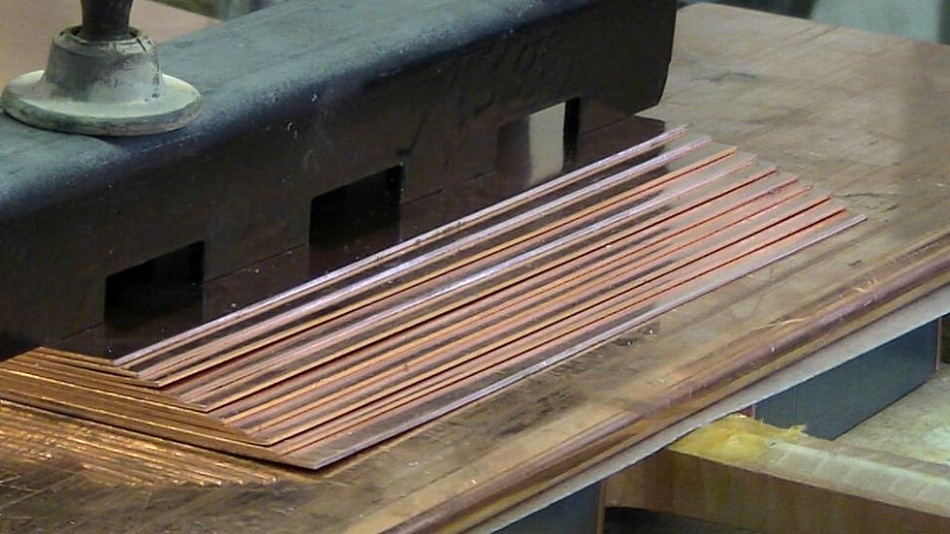

High-quality brazed connections play a vital role in the outgoing leads from bulk transformers. The transformed electricity leaves the installation through these solid copper bars. Thus, it is essential to connect these bars to one another with high precision and stability. This guarantees years of power transmission without losses.

In this example, the user selected a brazing process using brazing foil. An adequate amount of material is always present in the brazing gap and the brazed connection is also extremely uniform. In addition to this, the evenly distributed alloy provides a minimum amount of voids.

When brazing with brazing foil, the working temperature must be absolutely uniform and the heat must be applied with precision. eldec's technology helps assuring these factors. This indeed is attained by using a customized flat faced inductor along with a MICO-L 50 MF with 50 kW output and pyrometer temperature control. The device specifically excels in this area of application.

Induction brazing with precise application of heat

Transformer output

Benefits

- Solid components

- Rapid brazing

- Pyrometer temperature control

- Customized configuration

- High-precision control by pyrometer

- Economical energy consumption

Relevant Generators

This information has been sourced, reviewed and adapted from materials provided by Eldec Induction USA, Inc.

For more information on this source, please visit Eldec Induction USA, Inc.