In the past few years, it has become a typical practice to screen all incoming production materials within the pharmaceutical sector. This practice restricts both product liability and waste. As the EDXRF method does not considerably heat samples, it is applicable for both organic and inorganic material testing. Moreover, as a simultaneous method, detecting all elements (from Na to Am), the EDXRF is well suited for fast material identification.

Introduction

The Epsilon 3X is a high performance benchtop energy dispersive X-ray fluorescence (EDXRF) spectrometer that is fully capable of identifying materials. This has been described in this article.

The examples considered in this article are common materials used in the manufacture of pharmaceutical products. The fingerprinting method is applicable to all materials including powders, liquids and solids. FingerPrint software is available for the Epsilon 3 and Epsilon 3X range of XRF spectrometers.

Instrumentation

The instrument used was fitted with a molybdenum anode tube, six filters, a 50 kV and 1 mA generator, a helium purge facility (not necessary for all applications), a spinner, a high resolution silicon drift detector and a 10-position removable sample changer.

Sample Preparation

Loose powder standards and samples were simply placed into disposable P1 sample cups filled to an estimated depth of 1 cm.

Method Development

The ideal FingerPrint conditions were established using the standard feature: Optimize Conditions. Measurement times were 150 seconds per condition setting leading to a total measurement time of 300 seconds. The FingerPrint button was toggled to select the FingerPrint application.

This one-time arrangement includes selecting from a range of distinguishing factors controlling the Chi2 regression algorithm. Default settings are recommended for first-time use.

Create a Library - Measure Standards

When using the FingerPrint option, it is not essential to do any interpretation. A set of general use materials are just loaded and measured.

XRF Intelligence - Capturing Subtle Differences

The FingerPrint software uses a high-level statistical algorithm that inspects the entire scan. This includes features such as background profiles and peak shape.

A main advantage is that fingerprinting is a fully automated method without the need for interpretation.

General Use Materials Library Spectra

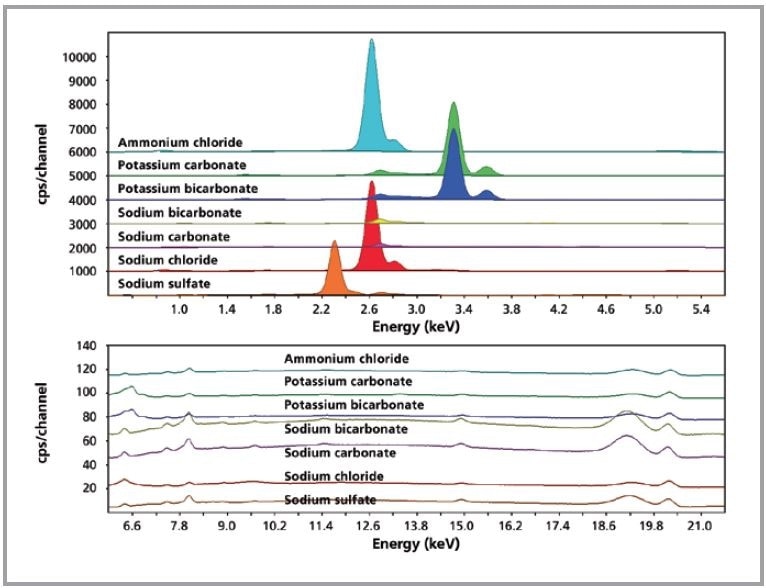

With the scan viewing function, spectra from samples and standards can be viewed as seen in Figure 1. This step is not essential but demonstrates the resolving power of the Epsilon 3X.

Figure 1. Example spectra from the reference library.

Measuring Unknowns

Unidentified samples were kept on the sample tray. Measurements were started once the corresponding sample positions were identified.

A new preparation of potassium carbonate was measured as an unknown.

Instant Identification - Results

The identification of the unknown is automatically conveyed. The unknown example was a match for potassium carbonate, as illustrated in Table 1.

Table 1. Candidate list expanded view.

| Instant identification (candidate list) |

Chi2* |

Confirmation** |

| Potassium carbonate |

0.01 |

Yes |

| Potassium bicarbonate |

3.2 |

No |

| Ammonium chloride |

676936.10 |

No |

* Statistically scoring candidates - lower Chi2 values are better matches.

** Only the lowest Chi2 values are considered a match.

Conclusion

This article clearly shows that the Epsilon 3X XRF spectrometer can be employed for fast FingerPrint identification of all samples including raw materials, excipients, reagents and final products. Both fingerprinting and elemental quantification can also be integrated in a single method.

This information has been sourced, reviewed and adapted from materials provided by Malvern Panalytical.

For more information on this source, please visit Malvern Panalytical.