Established in the 1890s, Pegler Yorkshire is one of the world’s major Manufacturers of sophisticated integrated heating and plumbing products.

The company’s dedication to customer service, engineering innovation and quality continues today as the organization deals with the challenges of water and energy conservation in its innovative development projects and product design.

The New Product Development department sought to invest its skill in the subjective assessment of the optimal tactile characteristics of its Thermostatic Radiator Valve (TRV) products, in the quest to remain class-leading in terms of customer satisfaction, durability and quality.

The room temperature is controlled by mounting the TRV onto central heating radiators and manual turning the TRV either decreases or increases the temperature setting. To maintain the desired ambient temperature, the integral thermostatic component regulates the flow of hot water through the radiator. An objective methodology to repeatedly measure the torque to turn characteristics of the rotational control was required.

Solution

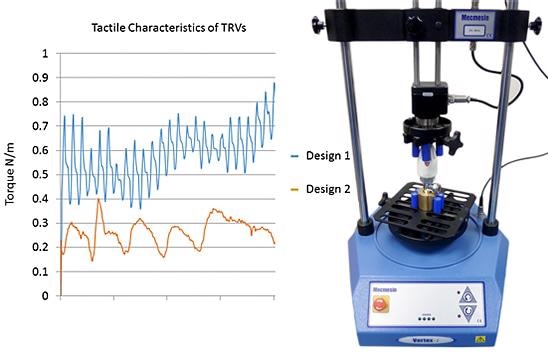

TRV undergoing torque to turn testing on the Vortex.

In addition to a Vortex-i computer-controlled torque test system, Mecmesin also delivered a selection of accessories and fixtures to grip a range of different valve geometries. The TRV is rotated in line with a representative benchmark test, from the minimum temperature setting to maximum temperature and returns to minimum again. The graphical results clearly show the changing torque level for this full-range angular cycle test, which can be correlated to the Engineer’s knowledge of preferred ergonomic characteristics and feel.

Emperor™ software enables the curves for alternative samples to be overlaid for comparison; this analysis offers important feedback for manufacturing optimization and iterative design.

Thanks to the comprehensive programming capability of the Emperor™ software, the NPD can write custom test programs that are configured to their specific requirements — to integrate unique experience into each product. Since the load cells can also be changed, flexibility is provided to maintain the proven accuracy of the results for future designs with inevitably different torque values.

System

- Large saddle plate, 10 N.m capacity

- Lower and upper fixing plates each with 4 pegs

- 6 N.m Intelligent Torque Cell (ITC)

- Vortex-i PC-controlled torque test system with Emperor™ (Torque) software (Superseded by the VortexPro automated torque tester and VectorPro software

Testimonial

Tactile characteristics have become a very important aspect in TRV design. The Vortex-i has enabled Pegler Yorkshire to benchmark and assess new design proposals allowing detailed examination of dynamic characteristics and wear over prolonged use. As a result we can provide customers with TRVs of an increased quality and durability.

Sam White, New Product Development Design Engineer, Pegler Yorkshire

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.