Vintech Industries Inc. is a global tier two provider of thermoplastic extrusion components to the non-auto RV and automotive industries. World famous OEM brands specify Vintech’s gimps, seals and weatherstrips as original equipment for trim, glass and closure sealing.

The company strongly targets the production of defect-free parts on time and is committed to programs of continuous improvement. Its Quality Control division tests to rigorous automotive industry standards, including GMW14712 and GMW14685. Vintech decided to bring the testing processes in-house in order to enhance the performance of their co-extruded designs.

In addition to increasing efficiency via reduced outsourcing costs, this investment brought significantly increased opportunities to win new customers, quicker turnaround times in design iterations for their customers, and added the ability to carry out other tests to its own internal specifications—functions earlier outsourced to material suppliers.

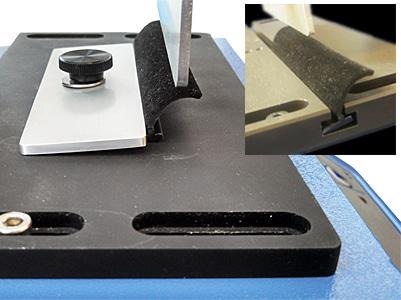

Beltline molding deflection testing, including T-slot locating design.

Solution

Mecmesin provided a 2.5 kN computer-controlled single-column test stand with a variety of fixtures and grips, a portable 500 N digital force gauge and a selection of compression plates to cover the number of testing procedures. In order to achieve a comprehensive suite of solutions, engineers from both companies worked on the specific requirements. Their solutions ranged from custom fixturing—easily interchangeable on standard mounts—to professional reporting back to the OEM client.

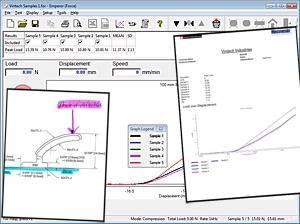

Emperor™ software allows the precise control of the test procedure, data acquisition and analysis of the results for a wide variety of tailored test methods dependent upon the part’s movement and functionality.

Compressibility of elastomeric components is amongst the growing library of programs; in order to ensure effective sealing forces in vehicle closure systems, as well as extraction and insertion forces of moldings to meet manufacturing ease-of-assembly and replacement—yet retain secure in service.

Complete solution: testing requirement, fixture design, results reporting to Vintech’s customers.

System

- Various fixtures, interchangeable baseplates, compression plates and grips

- AFG digital force gauge (500 N)

- MultiTest 2.5-i PC-controlled test stand (Superseded by the OmniTest universal test machine

Testimonial

Mecmesin has customer service which provide unwavering support for our questions and ALWAYS come through with the results and answers we have needed.

This solution continues to open doors for us and grow with our needs. It was everything we didn't know we needed and everything we could ask for. It is simple to use and can be mastered using very user friendly software and conversions into the programs we use every day. I look forward to taking our next steps with Mecmesin!

Terri Lebow, Quality Manager, Vintech Industries

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.