The innovative design of the MICO series combines the frequency converter and coolant system into a single housing. Small and compact, stationary or mobile, they are a practical and flexible solution for a wide variety of uses including:

- Annealing

- Induction brazing

- Hardening

- Coating and de-coating

MICO Induction Heating Systems

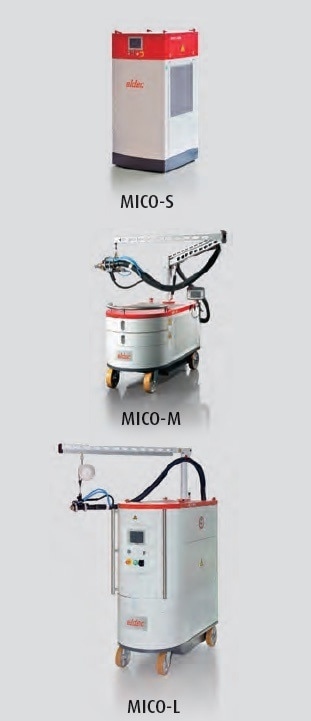

The MICO induction heating systems are offered in three models - S (stationary), M (mobile) or L (large). These are available in various power levels (from 15 kW to 70 kW) and sizes. MICO can be configured with crane hooks, rollers or forklift openings as well as with numerous work surfaces, and with a wide variety of tools, including: retractable arms with parallelogram kinematics; brazing pistol or heating cables and other auxiliary equipment; inductors; short or long arms and with special balancers. The simple touch screen makes operation easy.

The MICO modular kit for induction heating consists of the energy container (coolant system and generator), the stationary or mobile base plate and fixtures for tool handling together with the corresponding tools.

MICO-S Version

The MICO-S version occupies very little space and can be set up quickly. Weighing just 390 kg, it is easy to move around. Openings provided at the base plate allow for pick-up with a forklift or crane hooks.

All the systems are configured precisely to the demands of the customer, for example with coax cables of the correct length, a foot pedal, an arm with balancer, a pyrometer for temperature recording, etc. On request even twin generators are available. Consequently, users benefit from a very efficient and flexible energy source for induction heating and hardening.

MICO-M Version

The secret of the MICO-M generator’s success is its smart mix of quality, compact size and mobility. A MICO-M energy container includes the generator itself, the PLC system controller, the active coolant system and the hose bundle. The whole unit is on casters, so it is easy to move around. Customers may select between a high-frequency version (15 kW) and a medium-frequency (20, 25 or 30 kW).

The MICO-M has a wide range of applications. A few examples include:

- Brazing flat copper wires for machines

- Hardening forming tools

- Heating stress bolts in the construction of power plants

Once it is in place, users gain from the intuitive controller with its in-built touch screen. They have a mature, energy-efficient technology at their disposal that enables them to precisely control the amount of energy required.

These qualities are complemented by a wide range of options, including, the MICO-M’s ability to be fitted with parallelogram kinematics. This makes the handling of the cable and tool significantly easier.

MICO-L Version

The eldec MICO-L generator offers users a predominantly powerful, comprehensive solution that includes a coolant system. Medium (18 to 80 kW) and high-frequency devices (15 to 35 kW) are available. The L in the name of these induction heating systems stands for "large". In the medium-frequency version, the MICO-L supplies up to 80 kW for hardening and heating parts and components.

This powerhouse comes with a generator, controller, cooling system and hose bundle. It can be moved on casters as an option (a base plate for stationary use is always included) and is therefore available at all times. Inside, carefully selected high-performance components ensure precise and safe heating processes. The efficiency and reliability of these devices is the result of years of development and optimization by eldec.

The MICO-L can be fitted with a wide variety of inductors (tools), heating cables, brazing guns and auxiliary devices. This unit is a true all-round solution for induction heating and a wide range of effective heating processes needed in numerous industries.

This information has been sourced, reviewed and adapted from materials provided by Eldec LLC.

For more information on this source, please visit Eldec LLC.