Response time is defined as the interval in time a system needs to react to a given input. A challenge that many suppliers are faced with is decreasing response time while also maintaining accuracy and a high quality.

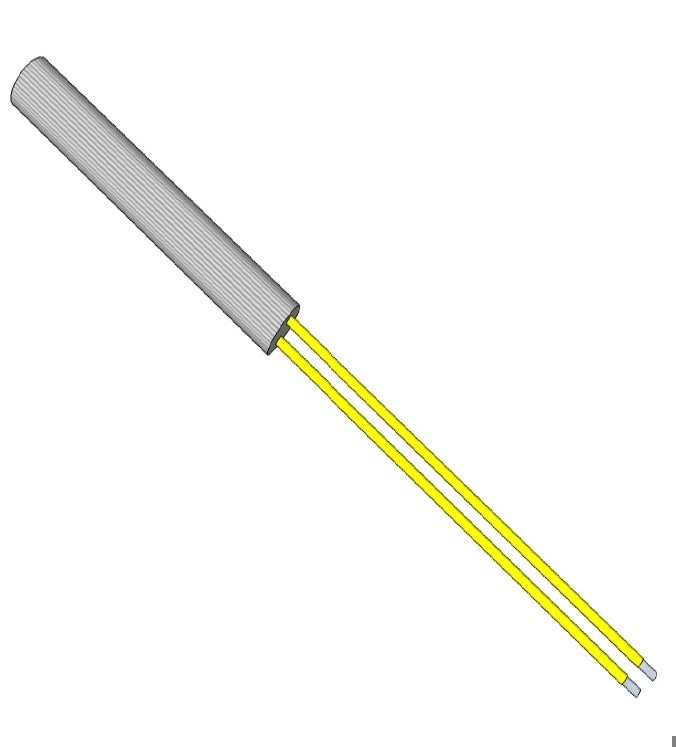

Temperature sensors are mostly employed in assembly constructions in order to protect the sensor element from an aggressive atmosphere or process media. Implementing sensors in end applications, sensor elements are often assembled into housings surrounded by epoxies, polyurethane or other polymer based materials.

Mostly, the sensor is placed in metal tubes surrounded by a thermal heat conducting paste such that the response time characteristics are enhanced. However, the thermal heat transfer of thermal conductive pastes is very limited owing to their polymer based nature.

Temperature Sensors - Directly Welded Wires - Innovative Sensor Technology IST AG

Advantages of Applying Metalized Backsides

In order to achieve the ever increasing demands in high accuracy and faster response time, Innovative Sensor Technology IST AG came up with a solution based on a standard RTD element. The element has been applied with a metalized backside, which enables the element to be soldered onto a metallic surface and thus increasing the thermal coupling, leading to a faster response time without compromising on high accuracy.

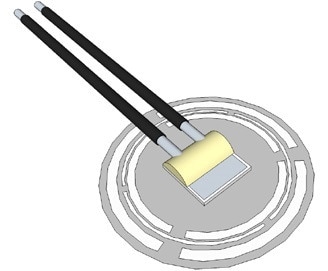

Sensor with metalized backside

Spoken in values, solder with a thermal heat coefficient of around 67 W/m*K is at least factor 3 better than characteristic heat conductor pastes with 10 to 20 W/m*K, thus yielding superior response times in comparison with conventional assemblies.

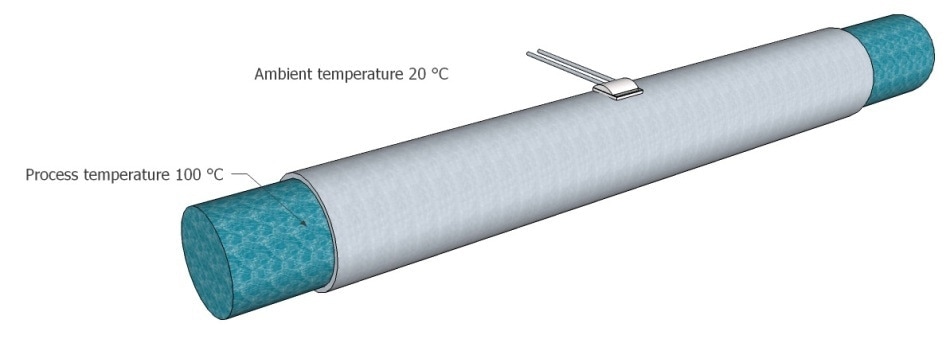

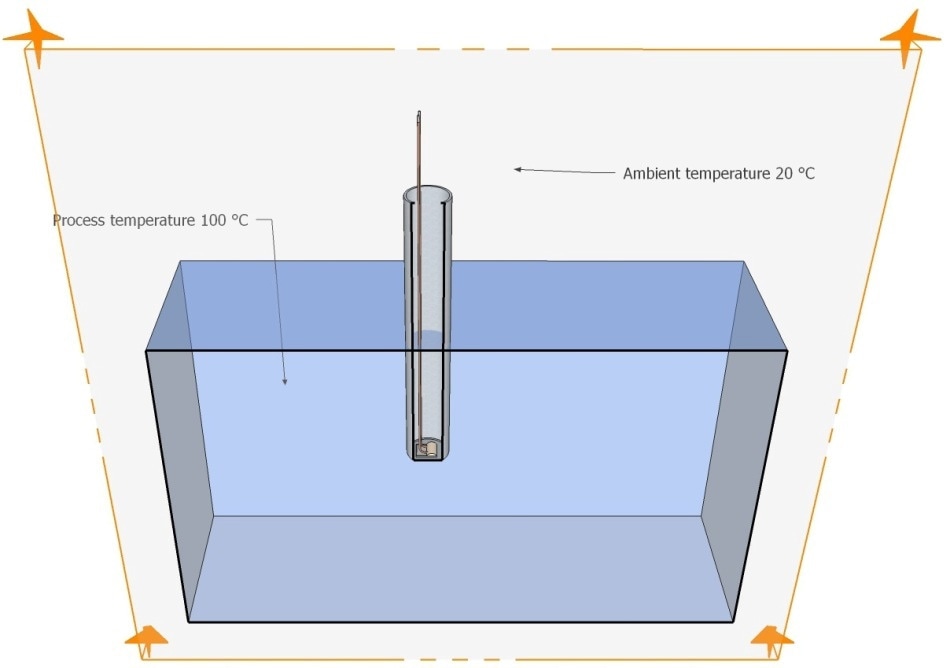

In other cases, sensors are placed into a process only some millimeters from the outside or – if pipe diameters are very low – placed on the outside of a tube.

Sensor immersed in metal tube and surrounded by a thermal heat conducting paste

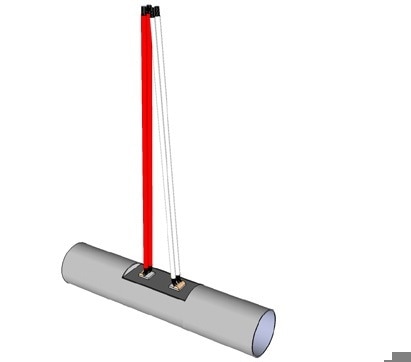

Sensor soldered on a tube - measurement is influenced by ambient temperature

Sensor soldered into the bottom of a tube – measurement is not influenced by ambient temperature

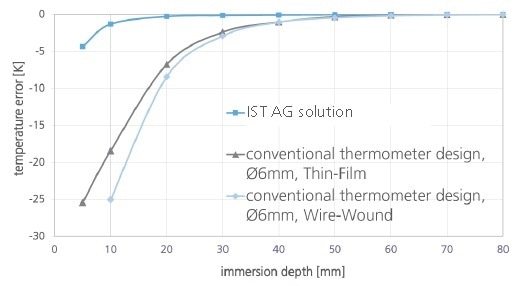

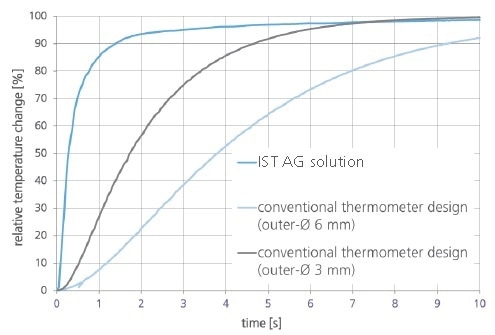

If the surrounding and process temperature varies significantly, these constructions lead to incorrect measurements which can often be noticed because of heat transfer from the surroundings to the sensor. The use of soldered sensors can considerably reduce this influence (Graphs 1 and 2).

By using the soldered metalized solution from IST AG, the required immersion depth is much lesser in comparison to a standard assembly.

Graph 1. Minimized immersion depth compared with standard RTDs.

Graph 2. Response time compared with standard RTDs.

In certain cases, the soldering process can cause changes in values or affect the accuracy because of the mechanical stress during the soldering process.

Hence, Innovative Sensor Technology IST AG offers sensors with metallized backside for soldering as well as constructions like soldered elements to tubes, in elements with individual tolerance classes, in caps or on metal discs on different metals to compensate for reproducible offset shift while soldering the elements to different metallic surfaces.

Sensor elements soldered onto metal tube

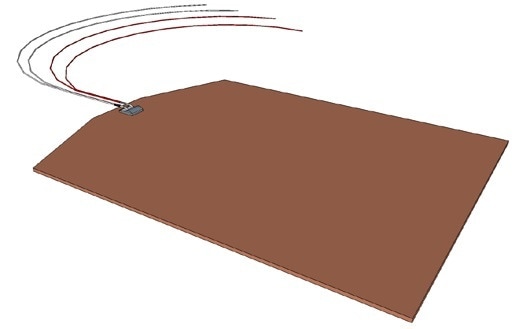

Sensor element soldered onto foil

Sensor element with inverted wires and metallized backside

Sensor element extended with 4 PTFE wires soldered onto Cu plate

This information has been sourced, reviewed and adapted from materials provided by Innovative Sensor Technology, USA Division.

For more information on this source, please visit Innovative Sensor Technology, USA Division.