One of the world’s largest building materials company, Saint-Gobain has been internationally recognized as a member of the Top 100 Global Innovators. Within the division of High-Performance Refractories, Spin-Works International Corporation has been brought in to expand the mission of Saint-Gobain – bringing sustainability to customer processes.

Spin-works is a manufacturing business, creating ceramic components to recover waste heat, reduce emissions and improve energy efficiency for customers involved with a broad range of high-temperature industrial processes.

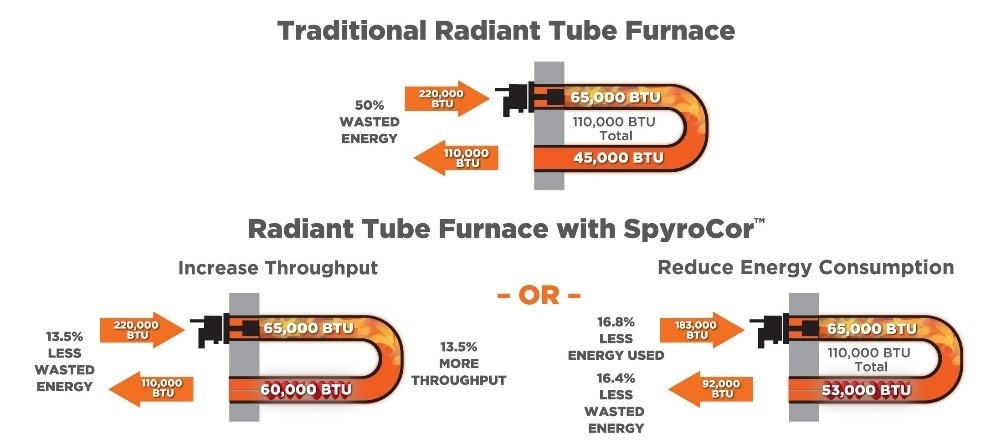

The SpryoCor™ are radiant tube inserts and a signature product of Spin-Works. When used, they create a uniform temperature in a furnace’s hot zone and therefore minimize the issue of exhaust leg ‘cold spots.’ In doing so, the inserts increase the efficiency of the furnace and can decrease energy consumption by up to 16%, with the furnace’s performance maintained at its usual level.

Frequently used in operations within the steel industry, SpyroCor™ can also lead to a reduction in emissions and even has the potential for gains in throughput.

With a multi-fin twisted, patented design, the SpyroCor efficiently captures wasted energy from the exhaust gases and radiates that energy back into the furnaces. By doing this, fuel input is reduced while still allowing enough energy to be available for the system load. Lower amounts of gas used also means that less CO2 and NOx is generated and released into the atmosphere. The ratio of gas used to emissions released is 1:1 – i.e., decreasing input by 15% leads to 15% fewer emissions.

However, throughput gains are produced if the energy inputs are kept the same. Using the same amount of input produces greater amounts of heat, which means that steel can be put through quicker and in a larger quantity.

A SpyroCorTM radiant tube insert (Image credit: Saint-Gobain)

The inserts are created from durable, thin wall silicon carbide, which allows them to be resistant to thermal shock. They are available in straight, U, W and tri-tube configurations.

SpyroCor™ radiant tube inserts’ installation process is rapid, which allows the effects to be seen immediately within a furnace. If upgrading to a new furnace, the inserts can be pre-installed or reused from a previous furnace installation.

Due to their many benefits, an investment return on the SpyroCor inserts can be realized within 18 months.

This information has been sourced, reviewed and adapted from materials provided by Saint-Gobain High-Performance Refractories.

For more information on this source, please visit Saint-Gobain High-Performance Refractories.