Silicon nitride-based ceramics present excellent thermal and mechanical properties and compete with traditional refractory materials for resistance to corrosive media and highly fluctuating thermal values, as well as offering mechanical properties similar to high strength metals.

The physical strength of a ceramic material in response to applied force is an important factor in determining its practicality in demanding industrial spaces. This relationship between proportional material deformation and applied stress is called Young’s modulus. This article reviews the Young’s modulus and modulus of rupture (MOR) of silicon nitride ceramic materials.

What is Young’s Modulus?

The Young’s modulus (E), i.e., the modulus of elasticity, of a material governs the level of applied force needed before it bends or breaks. It illustrates the constant ratio of tensile stress (σ) to tensile strain (ε) within the elastic limits of materials for tension as well as compressive forces. This property determines the force needed to enable engineered materials such as silicon nitride ceramics to deform and stretch.

The moduli of elasticity are determined by using the formula E = σ/ε and are usually expressed as a value of mega- or gigapascals (MPa or GPa).

Importance of Young’s Modulus

Young’s modulus is used to plot stress-strain graphs to ascertain the brittleness and malleability of a material in relation to its linear elasticity and stiffness. This information is highly crucial for components in harsh industrial environments since it has the potential to determine the tendency of the material towards elastic or permanent deformation under different thermodynamic conditions. Technical ceramics that have high Young’s moduli are widely applied in high-temperature and mechanically demanding applications for thermally critical components such as chemical thermocouple protection sheaths and molten metal handling crucibles.

What is the Modulus of Rupture?

The MOR of a material is different from its tensile strength in the sense that UTS defines the maximum stress that can be endured by a material before severe deformation due to stretching. In contrast, MOR refers to the point at which a material’s cross-section breaks as a result of bending.

The two properties are inherently connected. Upon testing a test piece or component under three-point-bend (3PB) conditions, the concave surface is subject to compression, whereas the convex surface elongates under tension as illustrated in the following schematic drawing, ultimately resulting in failure or rupture of the component.

.jpg)

In general, MOR is expressed in MPa of applied force and can be determined from the axial load (F) at the point of fracture, as well as the cross-section of the material.

Importance of Modulus of Rupture

MOR is crucial for the characterization of a material’s structural capacities in response to high axial loads. This is significant for load-bearing components needed to endure different types of thermodynamic stresses in harsh operating conditions. Silicon nitride ceramics for refractory environments usually demonstrate high moduli of rupture to resist fracture caused by bending and to guarantee long component services lives for even the most rigorous applications.

The Young’s Modulus and MOR of Sialon

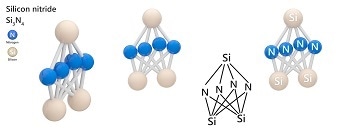

Sialon ceramics based on high-strength silicon nitride were developed as a cost-efficient solution to some of the most rigorous thermal processing and mechanical industrial environments. A tetrahedral arrangement of silicon–nitrogen bonds replaced by the addition of oxygen and aluminium offers excellent resistance to different types of thermodynamic stresses, with optimized resistance to corrosive attack. These properties are supplemented with high physical integrity and material strengths under applied forces.

Silicon nitride and sialon ceramics have some of the highest Young’s moduli known for engineered ceramics due to the highly dense composition of interlocking silicon nitride grains. The highest material stiffness is recorded at roughly 470 GPa — that of naturally occurring sapphires.

Silicon nitride and sialon ceramics exhibit an exceptional range of flexural strengths appropriate for different application requirements. Technical silicon carbide represents a 3-point MOR of 450 MPa, whereas silicon nitride-based ceramics display moduli of rupture that range from 500 to 945 MPa.

Sialon Ceramics from International Syalons

International Syalons is dedicated to the continuous advancement of technical silicon nitride ceramics for the most rigorous applications in the world. The company was among the pioneers to recognize the potential of silicon nitride-based materials to be applied to refractor applications, offering exceptionally high-strength and rigid materials for rigorous thermal and mechanical environments. Its sialon grades demonstrate different thermo-mechanical profiles appropriate for a range of profiling methods.

International Syalons offers multiple grades of silicon nitride ceramics with different Young’s Modulus and MOR, such as:

| Syalon Grade |

Young's Modulus (GPa) |

Modulus of Rupture at 20 ºC (MPa) |

Modulus of Rupture at 1000 ºC (MPa) |

| 101 |

288 |

945 |

700 |

| 050 |

306 |

800 |

750 |

| 501 |

340 |

825 |

- |

| 110 |

139 |

500 |

400 |

International Syalons designs and engineers highly innovative refractory materials and technical ceramics to the highest standard of certification. The company offers advanced silicon nitride ceramics that are appropriate for use in ferrous and non-ferrous metal handling, chemical processing and oil and gas recovery applications.

This information has been sourced, reviewed and adapted from materials provided by International Syalons.

For more information on this source, please visit International Syalons.