|

Heat treatment has changed beyond recognition since the first simple annealing and hardening cycles were discovered empirically hundreds of years ago. These changes have been driven by a better understanding of the underlying science, increasing demand for products and quality requirements, and latterly, social factors such as environmental considerations. In addition, the market has been shaped by technological developments, such as the changing use of materials and advances in manufacturing techniques, which have opened up new opportunities.

Hardening

The simplest process to benefit from technological progress is hardening. Although the vacuum furnace has existed for many years and pressure quenching is common, the latest generation of intelligent furnaces incorporate rapid controlled quenching with minimum component distortion. Step quenching can be carried out and process times are kept to a minimum by using convective as well as radiant heating during the cycle. Quench gas recovery systems also keep costs down and offer environmental benefits.

Case Hardening

Case hardening has evolved from using solid to liquid, and now, usually, gas as the enrichment source, but the next generation of technology uses vacuum, or plasma. The benefits are similar to those gained from plasma nitriding. However, work has to be done to introduce new materials to maximise the benefit of the new technology.

Nitriding

Changing from traditional gas nitriding to plasma nitriding will bring a host of benefits, including better control of the process and increased material types and product shapes that can be effectively treated. Ammonia is no longer used in the process and cycle times are shorter, so there are energy savings as well as environmental benefits. An increase in processing efficiency also follows from the shorter processing time.

Nitrocarburising and Oxynitrocarburising

The advent of ‘low temperature’ heat treatment processes, such as nitrocarburising and oxynitrocarburising, also offers many more options to treat components and tools, with very low risks of distortion or post-processing machining.

Laser Hardening

Laser hardening is a very efficient way of locally hardening large tools, producing virtually no distortion, dramatically increasing tool life, and, interestingly, borrowing much of its technology from the CAD/CAM used to make the tool. Compared with the alternative of flame hardening, it is light years ahead. Laser technology is also being used for surface modification, to replace shot peening in certain applications.

Hard Coatings

Another environmentally friendly technology gaining market share is hard coating. Even using the most skilled heat treater, it is often more cost-effective to treat or coat limited load bearing areas, rather than the entire tool or component. While there are heat treatment techniques to do this, plating and hard coating offer alternatives. Plating still has environmental problems, so the environmentally friendly technologies of hard coating provide viable alternatives.

Hard Coating Materials and Technologies

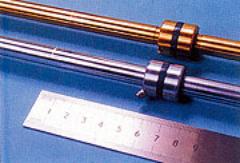

Coatings such as titanium nitride (TiN) and chromium nitride (CrN) are evolving as much as alloy steels evolved in the 20th century. Complex coatings such as titanium aluminium nitride (TiAlN) or titanium aluminium boron nitride (TiAlBN) are already being applied, and combinations with other elements such as yttrium are being researched. Multi-layer coatings, in which the composition changes throughout the coating, have been developed to maximise mechanical properties of the layer. Not only the coating, but also the deposition method can be matched to the application, and the three main deposition methods of electron beam, arc and magnetron all have their strengths and weaknesses. Of course, coatings can be applied to polymer surfaces, and while this has been mainly used for decoration so far, there are many potential engineering applications.

|

|

|

Figure 1. Titanium nitride coating (gold) achieves substantial wear reductions on aircraft components.

|

Carbon Coatings

Carbon, with its allotropy, has a unique part to play in surface engineering, since coatings can be applied with varying amounts of ‘diamond’ for wear resistance and ‘graphite’ for lubricity. This technology, together with ion implantation, will surely be developed to enable wholesale commercial coating of polymers in the near future.

Ion Implantation

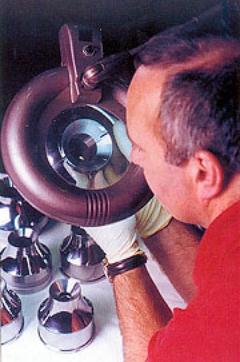

These hard processes operate at between 350°C-450°C, and their fine finish allows them to be applied to finished parts while maintaining design tolerances. However, in the case of polymers and certain steels, these temperatures are not low enough to totally avoid all undesirable material changes and distortion risks. Here, the relatively new technology of ion implantation offers significant benefits. Under vacuum at temperatures of less than 200°C, ions such as nitrogen can diffuse into the surface layers of metals and plastics to produce a very hard, but very thin layer, to extend product life or increase lubricity.

|

|

|

Figure 2. Component inspection for ion implanted parts

|

The Heat Treatment Industry

The changing use of materials and the cold wind of global competition from developing countries have made traditional heat treatment, plating and other technologies relatively uncompetitive. Nevertheless, the businesses that anticipate the needs of the market by capitalising on user education, process design and minimising costs by efficient processing are the ones gaining market share.

Component Cost Considerations

The extended choice now available underlies a sea change in the engineer’s view of heat treaters and coaters. Today, reduced total life costs are achieved by designing a system, one in which material choice is determined by how much the material can be modified by surface engineering to meet the requirement of the end user. This enables the development of innovative, high-performance products such as austempered ductile iron (ADI), which is used in applications that would never had been considered for cast iron in the past. The application of the correct thermal processes forms ADI and increases the material toughness to such an extent that it has been used to make road breaker bodies and automotive gears. The near net shape manufacturing process is, of course, much cheaper than machining wrought components.

The Current State of the Heat Treatment Industry

Today, heat treatment is a mature business, designing systems to meet engineering specifications, working closely with platers, hard coaters and other parts of surface engineering to reduce total life costs and enhance performance. Like every other business it also has to adopt new methods, reduce operating costs and reduce its environmental impact.

Materials Selection and Today’s Engineers

Yesterday’s engineers selected the material and, if it didn’t perform, they modified it. Today’s engineers should be selecting the material as the first building block in a system that combines structural strength, flexibility, surface hardness and lubricity, to meet the specification, as well as being cost-effective and reliably meeting the lifetime requirements. A tall order, but one that can be achieved by using the skills of the heat treater, the coater, and the ion implanter if, and only if, they are all considered as part of one system designed to satisfy the customer.

|