Mecmesin's Force and Torque test instruments and motorised systems enable beverage manufacturers to:

- Maintain consistency of manufacture and products

- Ensure the maximum standards of precise, consistent product quality such as minimal leakage, deterioration, or evaporation

- Ensure safety and security during storage, package integrity, distribution and display on the shelf

- Ensure package closures are sufficiently tight to form a tight seal while still being easy-to-open and re-seal by customers

- Control resources and costs

- Achieve greater efficiency, minimize waste and rework, maximize production, enhance yield.

- Comply with relevant standards

- Accomplish regulatory compliance with standards such as DIN 55440-1:99

- Adhere to environmental standards on the use of primary source material for PET containers.

Quality Testing Solutions for the Beverage Industry

Mecmesin force and torque test systems are used by numerous beverage companies including:

- Wineries

- Spirits distilleries

- Breweries

- Dairies

- Manufacturers of bottled water and soft drinks

- Manufacturers of sports drinks

The success of the introduction of screw cap closures in the wine industry can be attributed to the successful application of the closure itself. In order to determine a good application, you require reliable, accurate and consistent testing equipment. The Mecmesin closure torque testers have fulfilled all the criteria and have given us great confidence in our application of the screw cap closures.

Dean Zeunert, R&D Technical Manager, Orlando Wyndham Group, Barossa Valley

A Complete Product Range

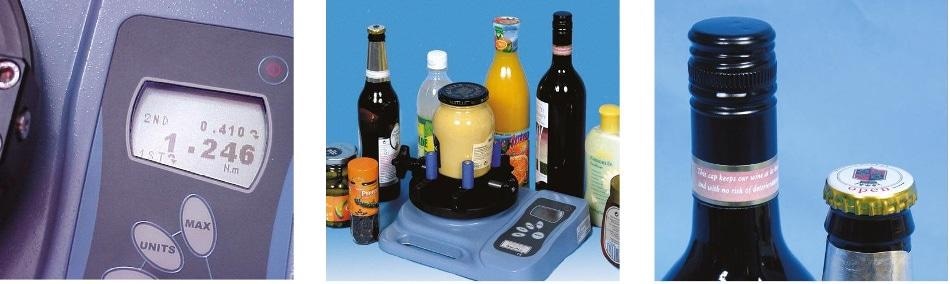

Mecmesin provides a range of economical measurement systems for quality control and production line testing in the beverage sector, including their MultiTest force testing systems, which range from simple systems integrated with a force gauge to completely motorized, computer-controlled force test systems, as well as a complete range of torque testing systems.

Quality Control Applications for the Beverage Industry

These force and torque testing instruments are used to carry out a wide range of quality control tests to measure, for example:

- Application and release torque of screw closures

- Pull-off force of crown closures

- Characteristic forces of “sports drinks” push-pull closures

- Slip torque and bridge torque of tamper-evident closures

- Top-load strength of aluminum bevcans and PET bottles

- Resistance of foil on drinks containers to piercing by a straw

- Tensile load associated with extracting “corks” from wine bottles

- Tensile force required to open a “ring-pull” can

- Peel strength of induction-sealed foils and labels

- Puncture force of flexible pouches

- Actuation force of “bag-in-box” dispensers

Orbis

The Orbis is a manually operated closure torque tester that delivers an economical solution for closure torque measurement applications. With its molded carry-handle and compact, lightweight housing, it has been built for easy usage and portability. It is perfectly matched for use in beverage manufacture and quality control areas.

Tornado

The Tornado digital torque tester is ideally suited for the testing of application and removal torque on caps and closures. Its ability to dtect initial bridge torque and peak torque make it the instrument of choice for testing closures with tamper-evident seals.

Application and Release Torque of Screw Closures

In the beverage sector, the opening torque of bottles and other containers with screw closures is a crucial quality check to guarantee:

- Minimal evaporation or leakage

- Integrity of the product during storage, distribution, and display

- Easy opening and resealing of the drink by consumers

Mecmesin offers a full range of torque testing systems for use in PET and plastic caps tamper-evident foil inserts in caps, testing screw closures, and aluminum caps with skirts.

The Mecmesin Orbis has helped us immensely with the introduction of screw cap closures. We love this unit because it is robust and easy to read on the large LCD display. This unit has been an integral part in testing screw cap closures; it has several times traveled with me to all corners of Australia. We chose the Mecmesin Orbis because of its reliability and robustness. It is great value for money especially compared to the old analogue units.

Andrew Wright, Operations and Logistics Manager, CSA Australia

Vortex

The Vortex range of motorized torque testing systems comprises of dedicated systems for measuring torques of screw closures and more. They can accurately and consistently test application and release torque up to 10 N.m (90 lbf.in) capacity. The Vortex range enables a constant and repeatable test speed to be fixed, thus eliminating the variability related with manually worked testers. The Vortex-i is powered by Emperor, flexible, robust, and user-friendly Windows-based software; it is ideal for production or laboratory use.

The Mecmesin Vortex gives us peace of mind that our process is in control on screw cap application. Our production line does half hourly checks for measuring the seal torque and the bridge break torque. The Mecmesin Vortex is a great instrument for us.

Ian Scrivener, Technical Manager Packaging, Hardy’s Wine Company

Top-Load Testing

Producers need beverage containers that comply with environmental standards restricting the use of materials, yet do not suffer top-load crush failures, both on the capping line or during stocking at various stages of the supply chain.

Top-load test systems based on a MultiTest test frame, force gauge, and vented compression plate are an economical and easy-to-use way to compute crushing load and to comply with top-load test standards such as:

- ASTM D2659-16

- ISBT Plastic Bottle Test Methods

Typical top-load testing system:

- Vented compression plate

- MultiTest-dV or OmniTest

- 1000-N loadcell

Regardless of which Mecmesin system is selected by customers, they can feel assured in the fact that numerous Mecmesin test systems and instruments are in use worldwide for beverage containers and countless other applications. Mecmesin has enjoyed more than three decades of proven success.

Furthermore, Mecmesin’s customers are supported by detailed technical information, service, calibration, and support facilities from the headquarters in the United Kingdom and its worldwide network of over 40 distributors and agents.

Peel Testing

When planning beverage containers, a balance must be established between realizing a strong effective seal that prevents contamination of beverage, while still being easy to peel back. A peel testing system from Mecmesin, based on an OmniTest test frame and specialized grips, can offer quick, repeatable, and accurate data to assess the quality and strength of container seals and adhesive bonds. Mecmesin peel testing systems also meet the necessities of the following standards:

- ASTM D1876-08

- BS EN 1895:2001

- ISO 11607

- ISO 11339:2010

Standard peel testing system:

- Specialized grips

- Intelligent 25-N loadcell

- OmniTest

We have always found Mecmesin’s equipment to be first class in its field. I would have no hesitation in recommending them to my colleagues within the industry.

Jon Gilroy, Quality Manager, Esterform Packaging, Leeds

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.