Mecmesin’s force, materials and torque testing systems offer the following benefits to packaging and packaging material manufacturers around the world.

Ensure Production Quality

Can the robustness and reliability of your packaging be easily determined? Can your customers be provided with indisputable evidence of production quality? Is it possible to ensure that your packaging will perform under storage and transportation conditions?

Mecmesin enables packaging materials and products to be manufactured to consistently superior quality.

Minimize Costs, Reduce Waste, and Improve Yields

Can the wall thickness of the PET bottle be reduced and made lightweight with no compromise on its strength? Can the surface roughness of the packaging material be reduced to cut down processing cycle time?

Mecmesin helps manufacturers to decrease material costs and realize lean manufacturing and environmental objectives.

Optimize Design

Do customers know the exact force needed to tear a packet, peel a seam, twist open a cap, remove a cork, pierce a foil, or actuate a pump on their packaging product? Does their packaging protect the product but remain easy for the customers to open?

With Mecmesin, customers can meet the usability requirements of packaging.

Conform to Standards

Is it possible to ensure whether the products meet all pertinent national and international criteria, as well as in-house specifications?

With Mecmesin, customers can consistently achieve regulatory compliance.

Quality Testing Solutions

Mecmesin’s force, materials and torque testing systems are suitable for testing a broad variety of packaging materials:

- Paper, for example, sacks and bags

- Metals, for example, foils and cans

- Textiles, for example, sacks and bags

- Plastics, for example, containers, bottles, plastic sheets, and closures

- Wood, for example, pallets and crates

- Corrugated cardboard

Industry Testing Solutions

Mecmesin’s complete packaging testing solutions cover a wide range of industry sectors, such as:

- Food and drink

- Cosmetics

- Household chemicals

- Pharmaceuticals

- Medical devices

- Transport and logistics

Cardboard boxes

Cosmetic packaging

Blister packs

PET containers

Tensile Testing

A simple tensile test is very useful in determining a wide range of packaging material properties and assessing the dissociation strength of jointed components.

Typical tests include elasticity, tensile strength, tear, peel, elongation, and joint strength.

For instance, tensile tests are used to find the strength and performance of heat-sealed or glued seams on foil or plastic packaging. As such, they offer a quantifiable evaluation to demonstrate whether packaging can be easily opened by a user, and they do not tear completely so that the contents do not spill out.

Standards

- ISO 1798:2008

- BS EN ISO 527-3:2018

- BS EN ISO 6383-1:2015

- BS EN ISO 11897:2001

- BS EN ISO 13934:2013

- TAPPI Test Methods

Tensile test on sports closure

Tear test on packaging material

Tensile strength of sealed joint

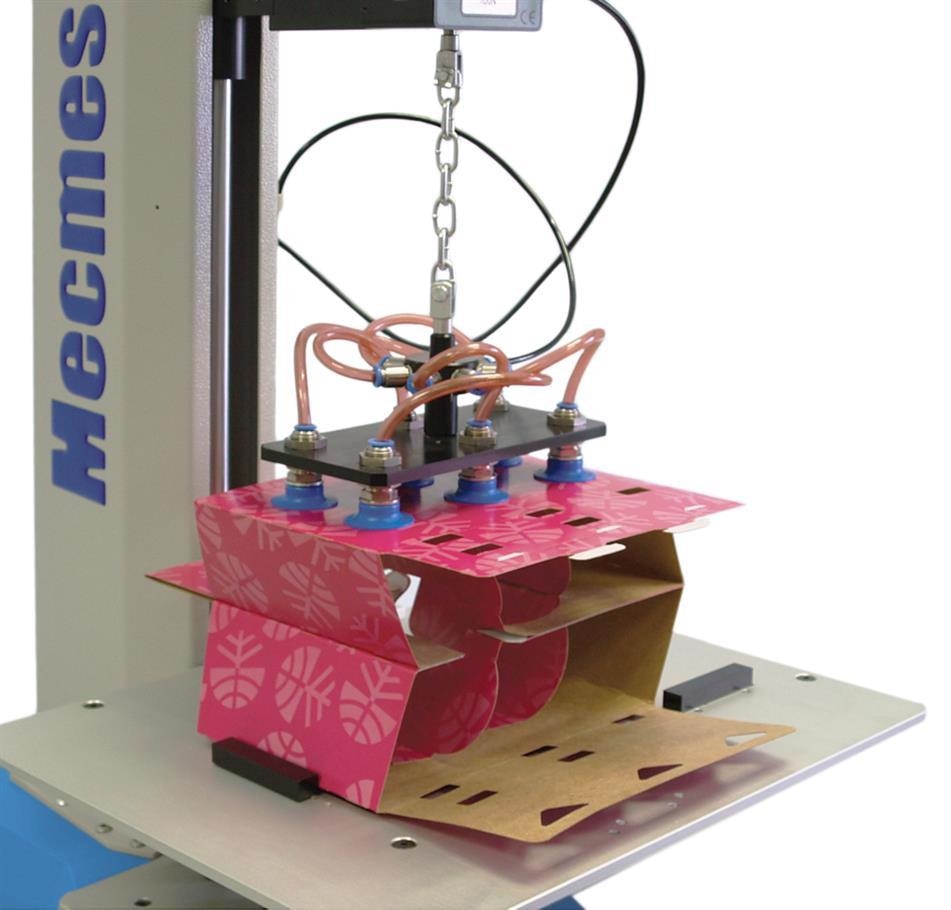

Tensile test on basket carrier

Top-Load Testing

Resistance to top-loading is one of the most important parameters in the design and quality of any container, from drums and PET bottles through to cardboard boxes, bevcans, and food tins.

With Mecmesin’s strong and compact top-load testing systems, both maximum compressive load and container free height can be quantified by just pressing a button. Accurate top-load assessment allows manufacturers to decrease material usage, reduce costs, and fulfill environmental standards, without affecting the compressive strength of the container during the filling, capping and distribution process.

Standards

- TAPPI Test Methods

- DIN 55440

- ASTM D4169-16

- ASTM D2659-16

- ASTM D642-15

- BS EN ISO 12048:2001

- ASTM D4577-05

- ISO 8113:2004

- DIN 55526

- ISO 3037

- ISBT Plastic Bottle Test Method 2004

Typical Top-Load Testing System

- 50-mm vented compression plate

- MultiTest 5-xt (Superseded by OmniTest 5 universal testing machine

- 2500-N intelligent loadcell

Our investment in the MultiTest 5-xt top-load test unit has paid for itself time and time again. The unit is so easy to use that no outside training was needed at start-up and training new operators was very minimal. This has resulted in no misjudgments from equipment set-up. The displayed graph makes it very easy to understand what is occurring during the test and aids in troubleshooting and correcting issues. The touch screen/computer combination reduces the footprint to less than half the size of our older unit. Overall the unit gives great performance at a very competitive price.

Dan McMillin, Quality Manager, Silgan Plastics, Kentucky, USA

PET bottles

Top-load test using a vented compression plate

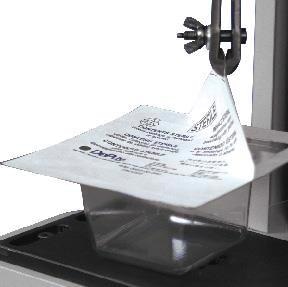

Peel Testing

Adhesive or heat-sealed joints and seams must be firmly formed to guarantee that the packed contents are protected and hygienic, but at the same time, the packaging should remain easy for the customer to open. Mecmesin’s peel testing system offers a quick, repeatable, and accurate technique for evaluating the force needed to start and propagate a peel on adhesive bonds and container seals.

Standards

- ASTM D1876-08

- ASTM F88/F88M-15

- BS EN 868-5:2018

- BS EN 1719:1999

- BS EN 1895:2001

- ISO 11339:2010

- BS EN ISO 11607-1:2017

- FINAT Test Methods

Typical Peel Testing System

- 50 N intelligent loadcell

- MultiTest 2.5-i (Superseded by OmniTest 2.5 universal testing machine)

- Dedicated fixtures

Medical packaging peel test

Induction sealed foil tab test

Coefficient of Friction Testing

Form-fill-seal converting machinery must move, feed, form, stretch, cut, weld, and apply tensile load to raw packaging materials at high speeds.

The surface roughness of the material has a significant effect on the ease with which this may take place and thus the efficiency of the converting process. A valuable parameter for characterizing the surface roughness of the material is the coefficient of friction (COF).

Standards

- TAPPI T49

- ASTM D1894

- ISO 15359

Typical Coefficient of Friction Testing System

- OmniTest universal testing machine

- Coefficient of sliding friction sled fixture

Production of packaging material

Carton production line

Foils and films

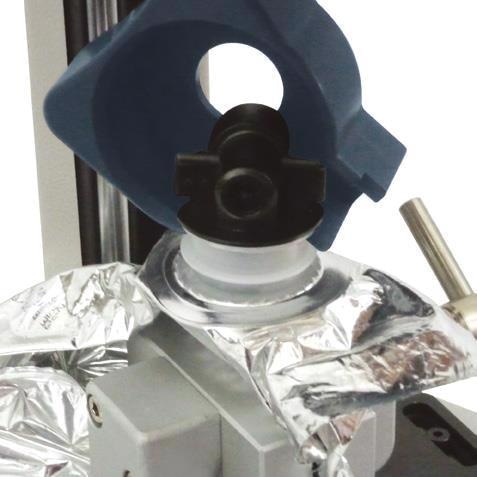

Cork Extraction Testing

A bottle cork must form an adequately tight seal to guarantee that the contents are uncontaminated, while at the same time it should also remain easy to open. The CombiCork Extraction Tester from Mecmesin determines the release twist torque of a champagne/sparkling wine cork or spirit bottle stopper, as well as the extraction pull-out force of a classic still-wine cork.

The “Combi” Cork Extraction Tester is developed in collaboration with and authorized by Oeneo Boucharge, one of the top cork manufacturers in the world, and it enables:

- Evaluation of cork seal integrity to reduce cork taint

- Setting up a reliable standard of product quality

- Optimization of cork design whilst still allowing easy opening

Standards

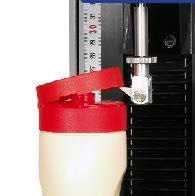

Typical Cork Extraction Testing System

- Combi Cork Extraction Tester

- Cam-operated Fixture

- Bottle Cradle

As a responsible supplier we are committed to ensuring safety within our products. The solution provided by Mecmesin means we can monitor the extraction force of our corks to guarantee our customers receive a consistent end product.

Frederic Junge, Oenologist– Quality Manager, Sibel SA–Oeneo subsidiary, France

In addition, Mecmesin provides a Combi Cork-i testing system, which can simultaneously measure both the extraction force and torque needed to pull and twist a cork from a sparkling wine or spirits bottle.

Cork extraction test

Synthetic corks

Extraction testing of whisky stoppers

Natural corks

Aerosol and Pump Actuation Force Testing

The delivery of products such as liquid soaps, perfumes etc. relies on the performance of aerosol or pump dispensers. A simple compression test carried out on aerosols or hand pumps e.g. on liquid soap bottles, to a pre-determined displacement accurately determines the actuation force of spring-operated dispensers.

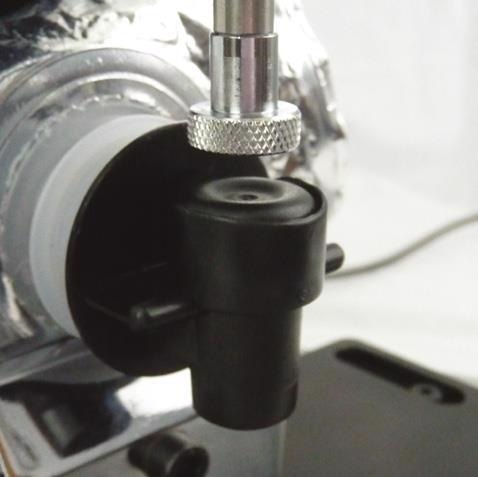

To conduct the test, the container is positioned underneath the crosshead/loadcell of a motorized compression testing machine and a small compression plate is brought down above the central axis of the pump/aerosol. This is compressed to a preset displacement and the maximum force recorded is the pump/aerosol actuation force.

Standards

Typical Pump Actuation Force Testing System

- 12 mm compression plate

- MultiTest 2.5-xt (Superseded by OmniTest 2.5 universal testing machine

- 250 N intelligent loadcell

Actuation force test

Spray cans

Actuation force of tap dispenser

Ring-Pulls and Snap-Caps Testing

Ring-pulls are found on food tins, beverage cans, and tennis ball tubes and must have the ability to endure an adequate level of tensile loading to open the pack, without being separated from the lid. The quality and suitability of the ring-pull mechanism can be evaluated with a simple tensile test on a ring pull.

Snap-caps must lock firmly with a positive click on closure, but it should also be easy enough to be opened. Mecmesin’s motorized force testing system enables easy testing of the compressive force needed to click shut a snap-cap as well as the tensile force needed to open it.

Standards

- ISBT Plastic Flat Top Closure Test Methods

- ISBT Sports Closure Test Methods

Typical Ring-Pull and Snap-Cap Testing System

- Test hook and flip-cap accessory

- MultiTest 2.5-xt (Superseded by OmniTest 2.5 universal testing machine

- 250 N intelligent loadcell

Ring-pull test

Snap-cap test

Sports closures

Torque Testing

A vital process in the production of well-designed and consistently manufactured screw closures is torque measurement. A broad range of torque testing equipment from Mecmesin serves nearly any closure torque testing application, from tamper-evident beverage bottles to child-resistant pharmaceutical containers.

Tamper-Evident Closures

The Tornado Digital Torque Tester from Mecmesin has been developed to measure the two vital torque peaks related to tamper-evident closures. One peak is called the “slip” torque, which is the effort needed to start the movement of the cap, and the other one is the “bridge torque,” which is the smaller, secondary effort needed to break the plastic bridges between the cap and security ring.

Closure Torque

When processing screw closures, it is necessary to apply adequate torque to ensure an airtight seal within the lid; however, the torque must not be too much or else it might damage the closure lining. A Mecmesin torque tester positioned at the point of production enables simple in-line checks to be carried out effortlessly. This guarantees that the capping heads constantly apply the right torque levels.

Child-Resistant Closures

When child-resistant closures (CRCs) are designed, a fine balance between security and accessibility must be achieved. The CRC Tester from Mecmesin can simultaneously measure both compressive force and torque to characterize the “push and twist” action required in opening a CRC. In addition, the CRC Tester may be used to evaluate the reverse ratchet torque of CRC closures.

The success of the introduction of screw cap closures in the wine industry can be attributed to the successful application of the closure itself. In order to determine a good application, you require reliable, accurate and consistent testing equipment. The Mecmesin closure torque testers have fulfilled all the criteria and have given us great confidence in our application of the screw cap closures.

Mr Dean Zeunert, R&D Technical Manager, Orlando Wyndham Group

Stelvin closures

Child-resistant closures

PET bottle cap test on a Tornado Digital Torque Tester

Child-resistant closure test

Any Size or Shape

It is possible to place even awkwardly shaped containers easily in the versatile mounting table, and it is a feature of all Mecmesin torque testing equipment. Movable gripping pegs may be simply repositioned to orient the closure above the central axis of the mounting table. Furthermore, Mecmesin can provide custom-engineered gripping accessories including a wide range of cap mandrels.

Standards

Tornado

Torque Testing Systems

- Manually-controlled, digital testers

- Orbis

- Tornado

- CRC Tester

- VTG Tornado

- Motorized, semi-automated system

- Motorized, touch-screen controlled system

- Motorized, computer-controlled system

The Mecmesin Vortex gives us peace of mind that our process is in control on screw cap application. Our production line does half hourly checks for measuring the seal torque and bridge break torque. The Mecmesin Vortex is a great instrument for us.

Mr Ian Scrivener, Technical Manager Packaging, Hardy’s Wine Company

Cosmetic packaging

Torque test on a Stelvin closure

Plastic screw cap closure test

This information has been sourced, reviewed and adapted from materials provided by Mecmesin.

For more information on this source, please visit Mecmesin.